Dustproof heat dissipation device for electromechanical equipment

A technology of electromechanical equipment and heat dissipation device, which is applied to the structural parts of electrical equipment, electrical components, transportation and packaging, etc. It can solve the problems of dust coverage and poor heat dissipation effect, achieve uniform heat dissipation, improve heat dissipation efficiency, improve heat dissipation and dust removal effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

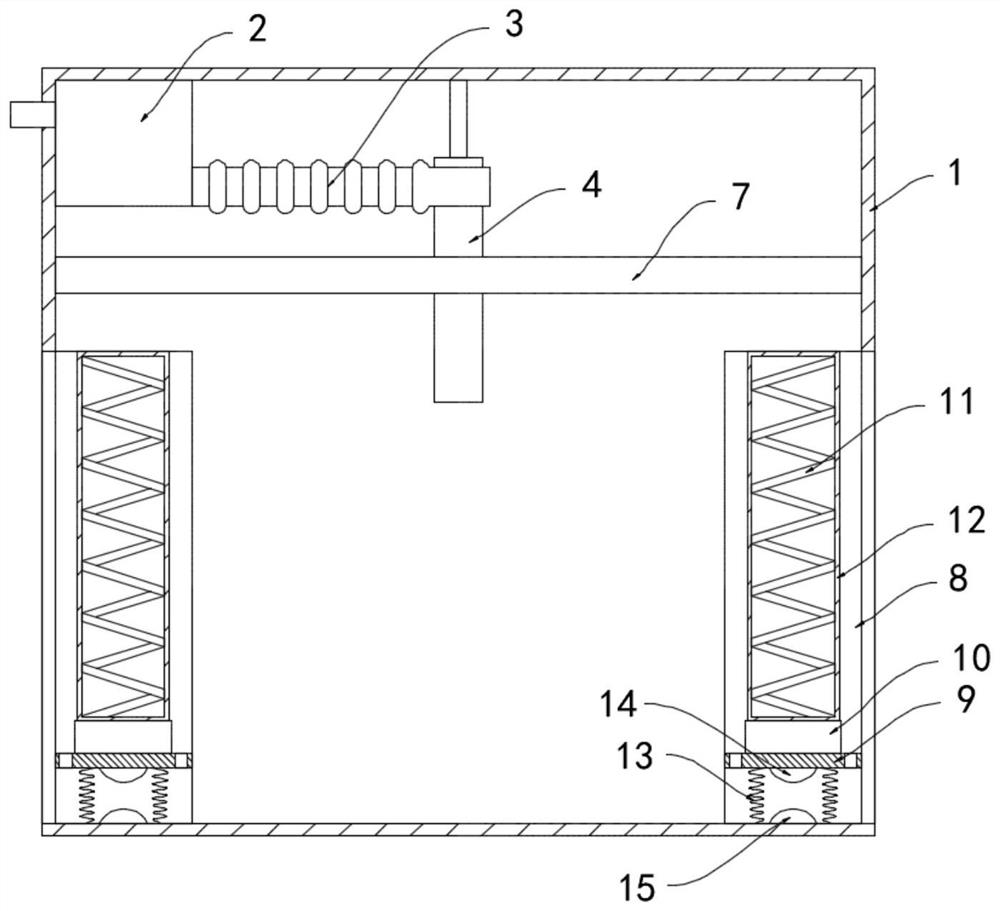

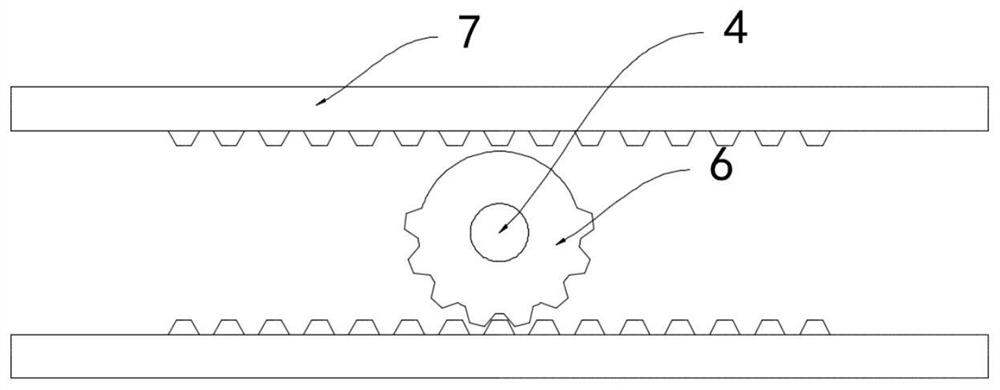

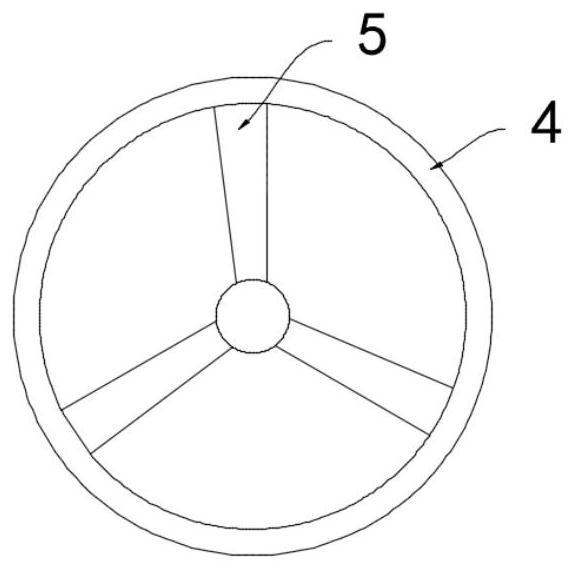

[0022] like Figure 1-3 As shown, a dust-proof and heat-dissipating device for electromechanical equipment includes a casing 1, a suction fan 2 is installed on the inner top surface of the casing 1, and the air outlet of the suction fan 2 is extended to the outside of the casing 1. The suction fan The air inlet of 2 is fixedly connected with a bellows 3, and the other end of the bellows 3 is rotatably connected with a vertically arranged suction pipe 4, and the inner wall of the suction pipe 4 is fixedly connected with a horizontally arranged fan 5, and the suction pipe 4 A half ring gear 6 is fixedly sleeved on the outer coaxial, and racks 7 are fixedly connected to the inner walls of both sides of the housing 1, and the half ring gear 6 meshes with two racks 7 respectively.

[0023] The side wall of the housing 1 is provided with two vertical air intake slots 8, the inner side wall of the air intake slot 8 is slidably connected with a slide plate 9, the upper surface of the ...

Embodiment 2

[0028] like Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that: the bottom of the housing 1 is fixedly connected with a dust collection tank 16, a through hole is provided through the sliding plate 9, and openings are provided on both sides of the dust collection tank 16. The air outlet of the suction fan 2 is fixedly connected with a blowing pipe 17, the lower end of the blowing pipe 17 is extended to the dust collection tank 16, and the outlet end of the blowing pipe 17 is arranged horizontally.

[0029] In this embodiment, the ash shaken off the surface of the dust filter net 12 settles downward, passes through the through hole in the sliding plate 9, and falls into the dust collection tank 16 for collection, which is convenient for removal. When the suction fan 2 works, the blowing pipe 17 The discharged wind is introduced into the dust collection tank 16 and flows quickly in the horizontal direction to blow off the dust in the dust collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com