Flue waste heat recovery heater

A flue waste heat and heater technology, applied in lighting and heating equipment, removing solid residues, reducing greenhouse gases, etc., can solve the problems of easy formation of scale in heating pipes and affect heating efficiency, etc., to improve the effect of heat dissipation and improve Heating efficiency and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

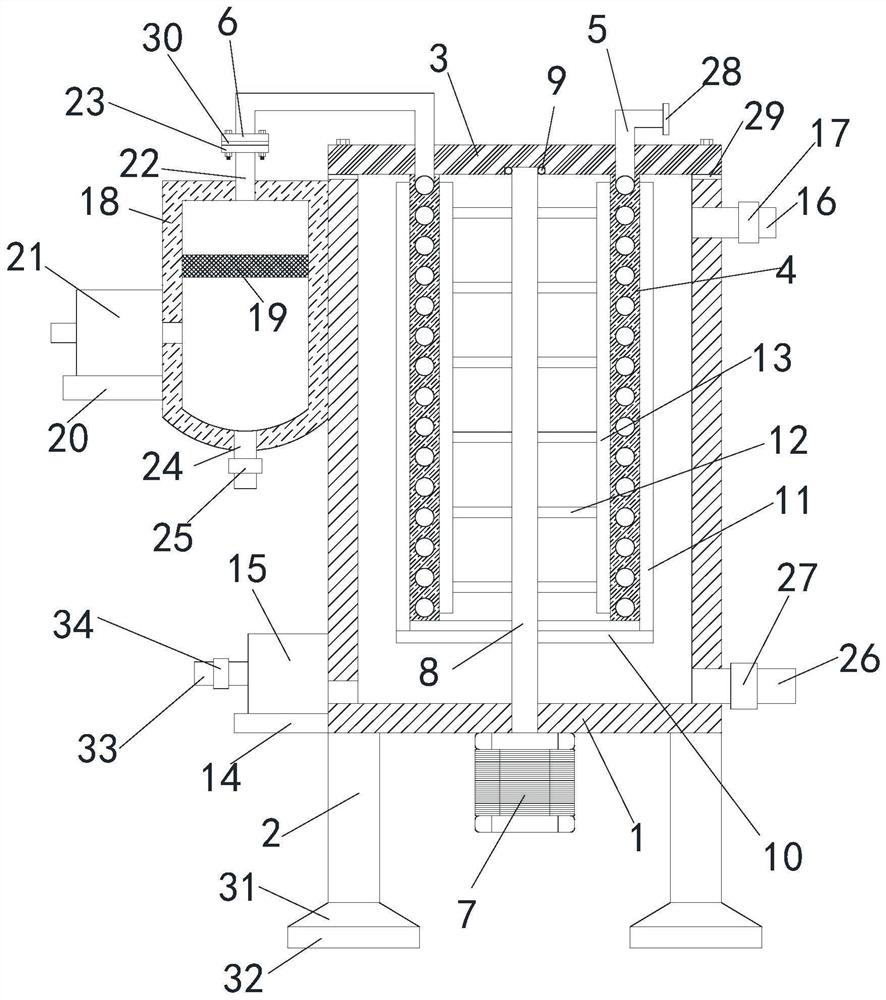

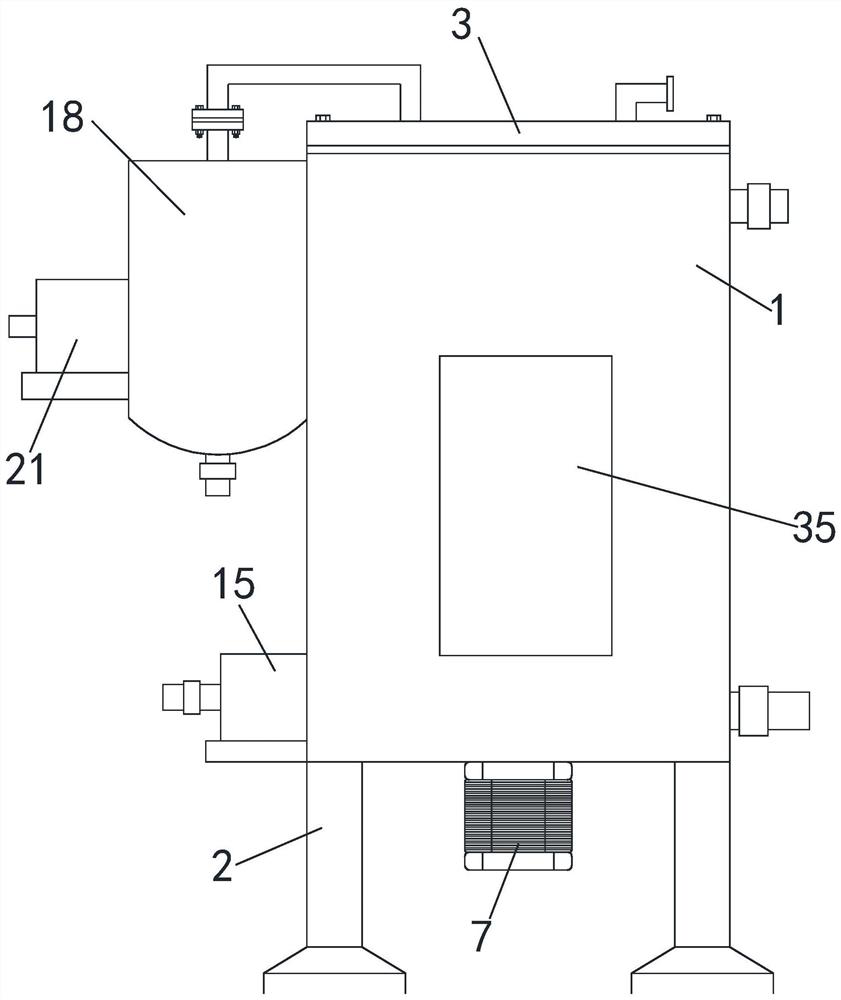

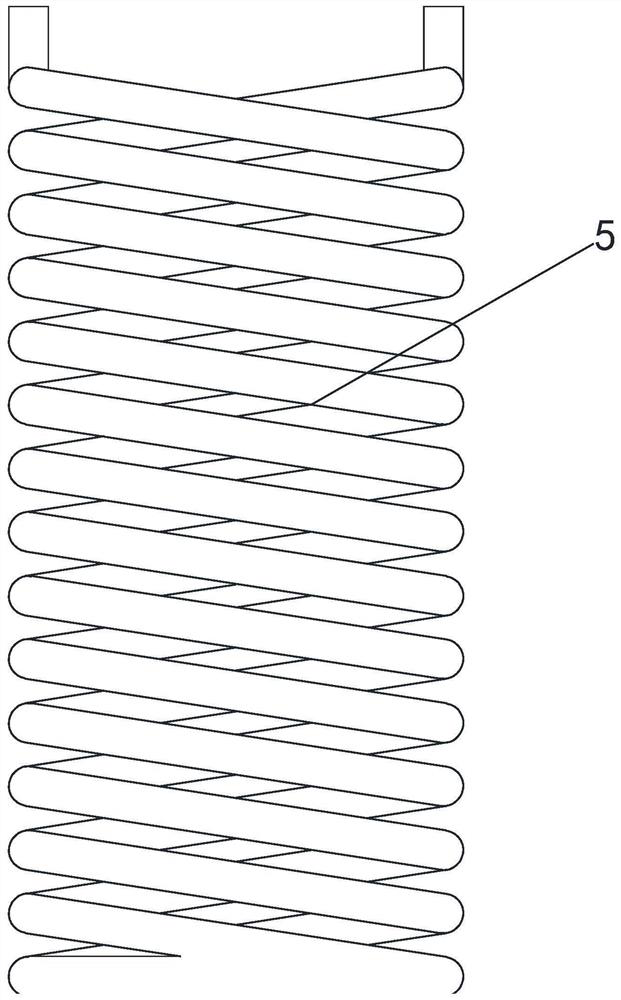

[0029]SeeFigure 1-3, A flue waste heat recovery heater, comprising a box body 1, four legs 2 are fixedly connected to the bottom end of the box body 1, and the bottom ends of the four legs 2 are fixedly connected to a support 31, The bottom end of the seat 31 is fixedly connected with an anti-skid pad 32. The four supports 31 increase the contact area of the leg 2 with the ground. The anti-skid pad 32 increases the friction between the leg 2 and the ground to improve the stability of the heater. The front end of the box 1 is provided with a square groove penetrating the inside of the box 1, and the inside of the square groove is fixedly connected with a transparent baffle 35. The transparent baffle 35 facilitates the observation of the inside of the box 1. The top end of the top plate 3 is fixedly connected with the top plate 3 by screws, and the bottom end of the top plate 3 is fixedly connected with a sealing ring 29, and the bottom end of the sealing ring 29 contacts the top en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com