Aluminum alloy angle iron extruding and recycling device

A recycling device and aluminum alloy technology, applied in the field of aluminum alloy angle iron extrusion recycling device, can solve the problems of inconvenient loading and unloading, occupying a large space, unable to carry out regular recycling processing, etc., and achieve the effect of easy folding and efficient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

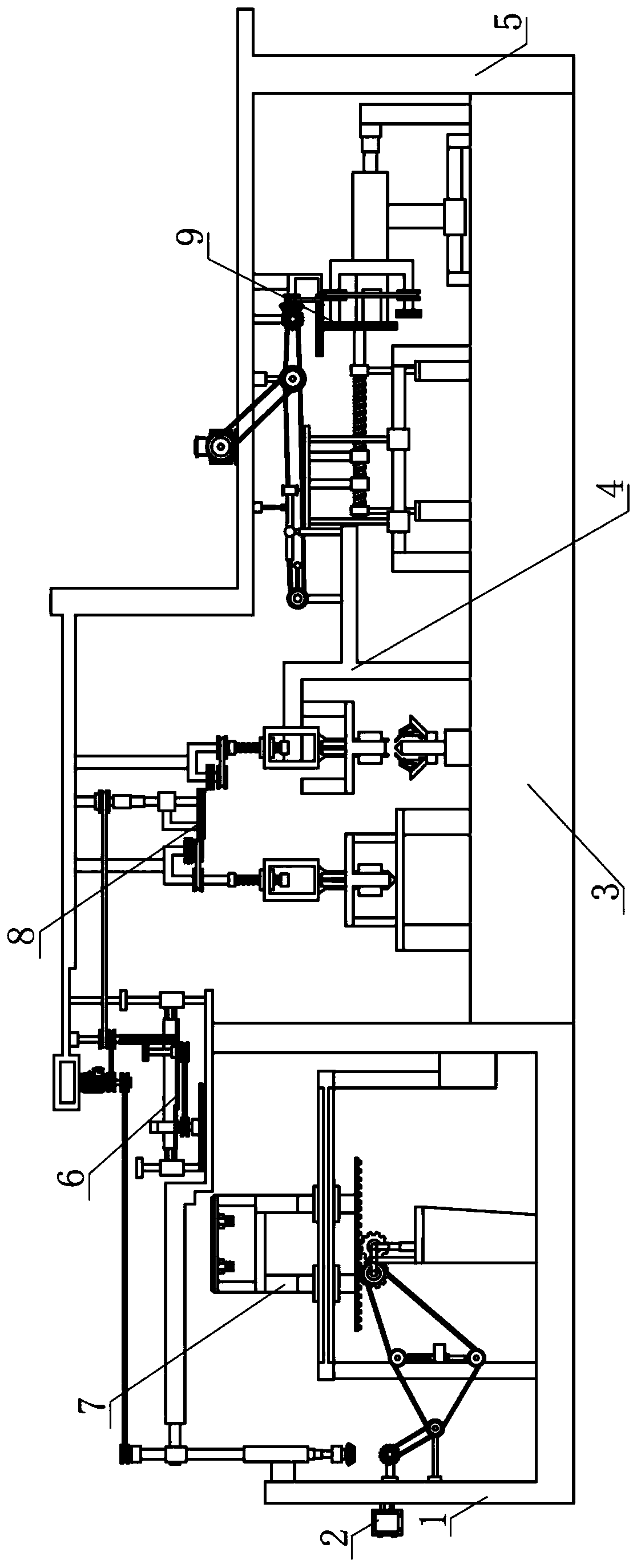

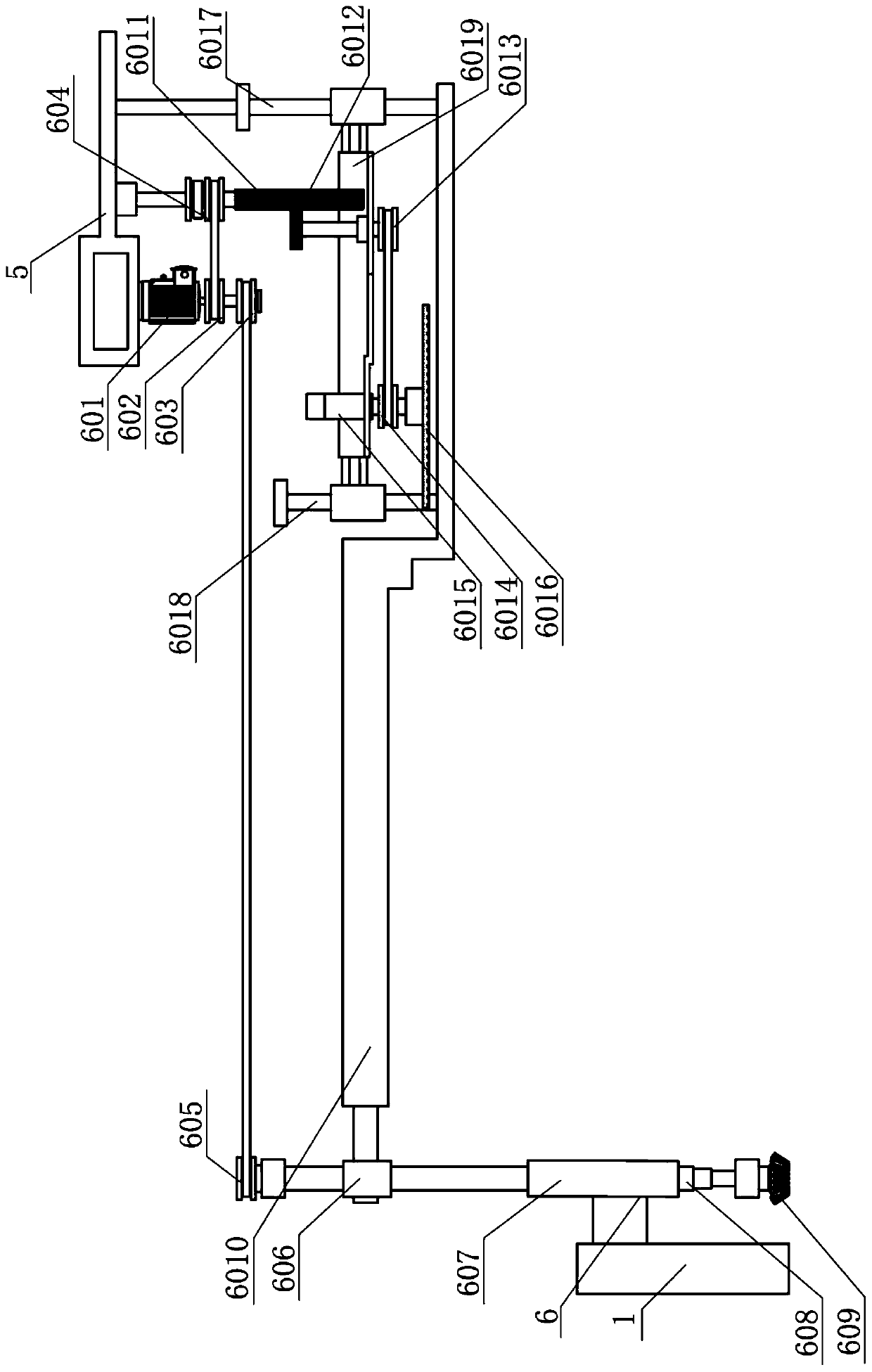

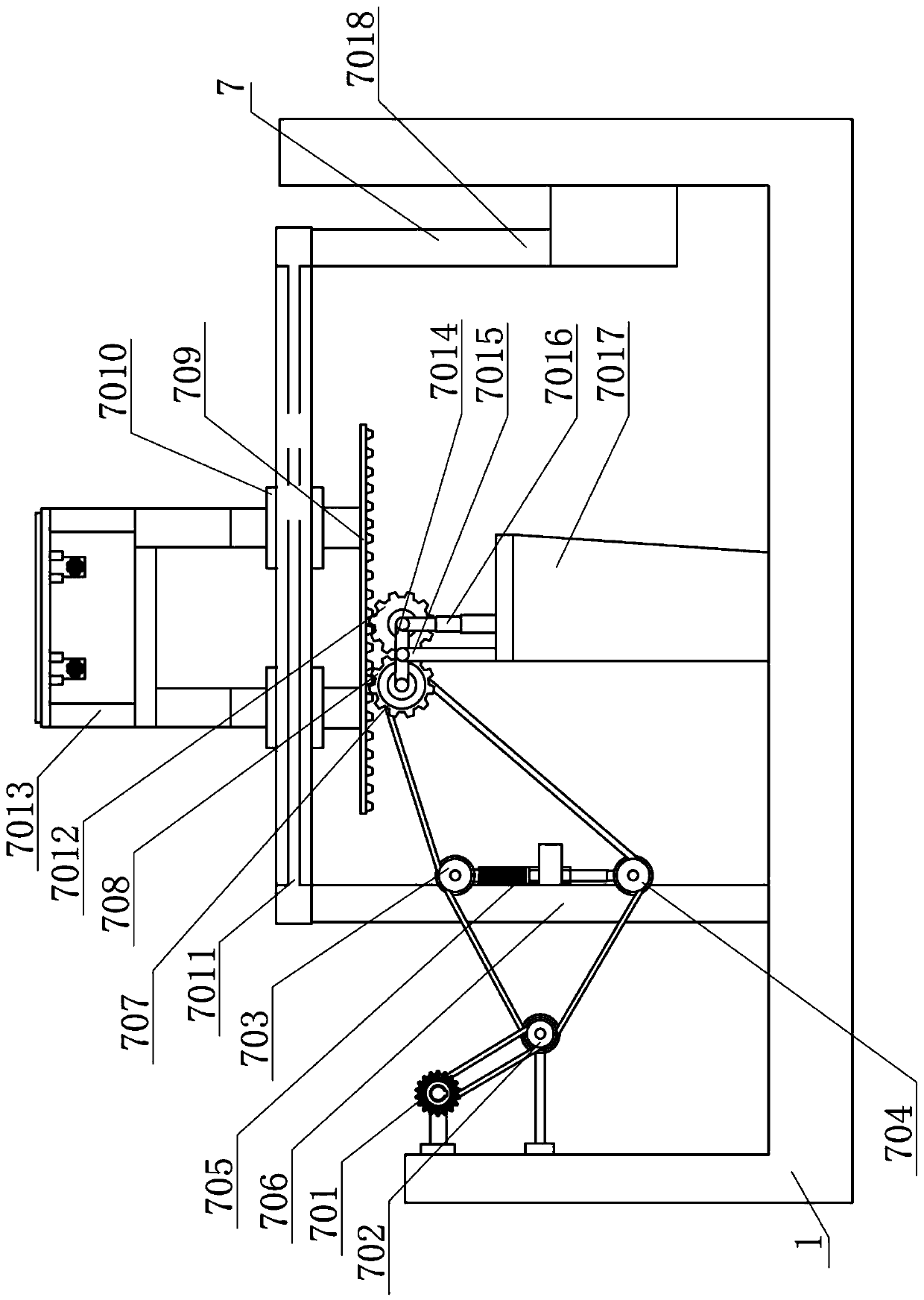

[0028] An aluminum alloy angle iron extrusion recovery device, including a left frame 1, a running monitoring control panel 2, a right bottom plate 3, an inner connecting frame 4, a right top frame 5, a suspension corner cutting mechanism 6, a circulation mechanism 7, and a pressurized counter Folding mechanism 8 and connecting plate separation mechanism 9; the middle and upper part of the left end of the left frame 1 is provided with a running monitoring control panel 2; the bottom of the right end of the left frame 1 is connected with the right bottom plate 3; 6 are connected; the inner side of the left frame 1 is provided with a circulation mechanism 7; the left side of the top of the right bottom plate 3 is connected with the inner connecting frame 4; the right end of the right bottom plate 3 is connected with the right top frame 5, and the bottom of the right top frame 5 is left The side is connected with the suspension corner cutting mechanism 6; the left side of the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com