A positioning fixture for star sleeve

A technology for positioning fixtures and star sleeves, applied in the direction of the chuck, etc., can solve the problems of inconsistency in size and the influence of star sleeve machining accuracy, etc., and achieve the effects of reducing the possibility of deformation, facilitating restrictions, and reducing the possibility of deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

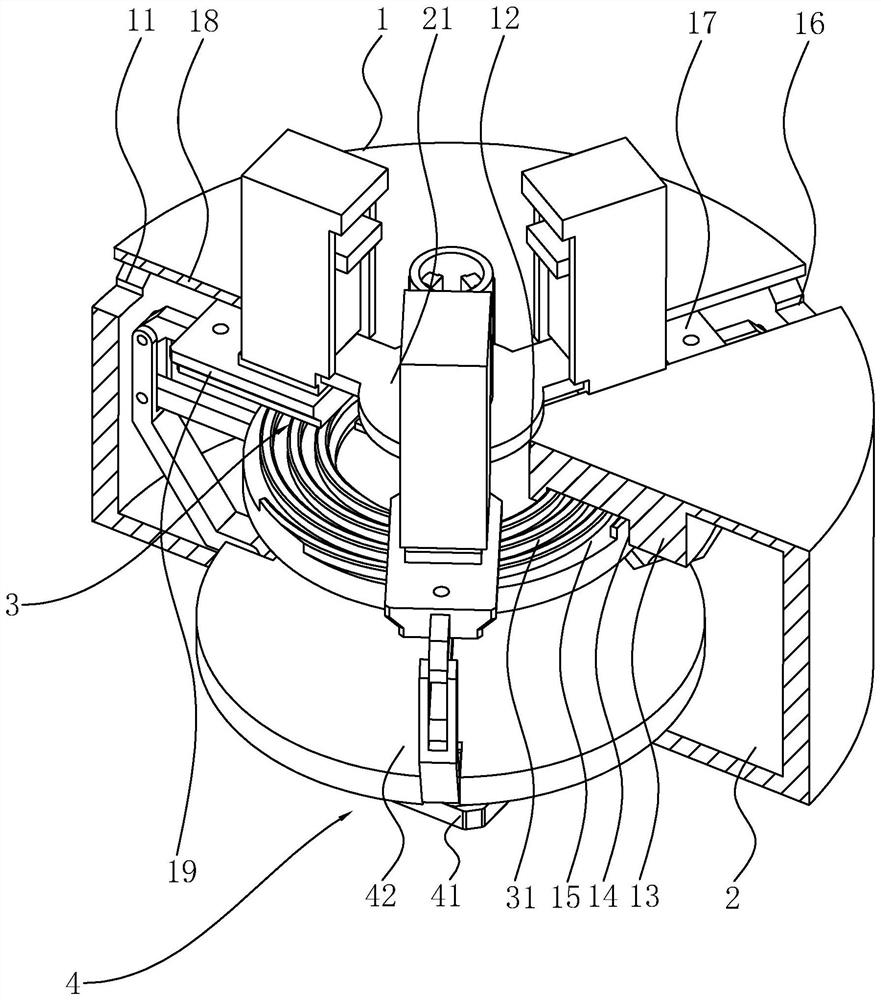

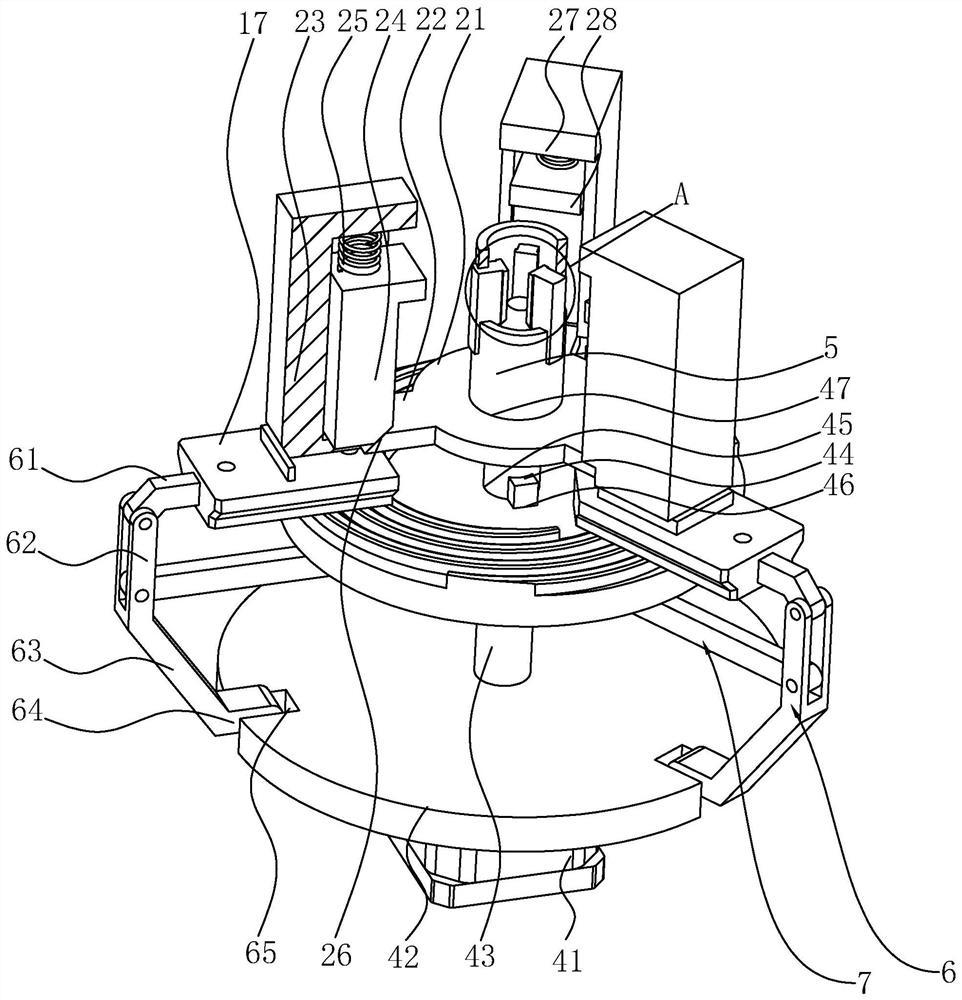

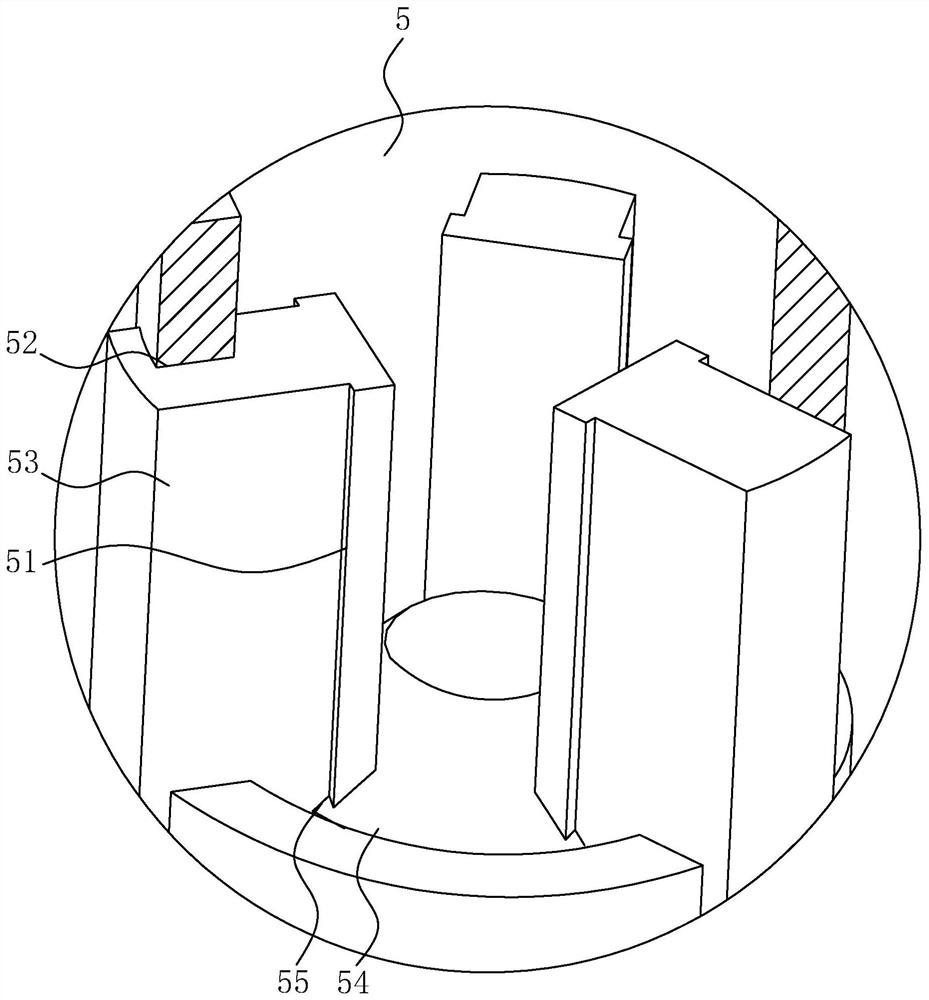

[0034] Embodiment: A kind of positioning fixture for star sleeve, as figure 1 As shown, it includes a box body 1, a circular cavity 2 opened in the box body 1, a first circular through hole 12 opened on one side of the box body 1 and communicated with the circular cavity 2, fixed in the circular cavity Cavity 2 is close to the fixed seat 13 of the first circular through hole 12 side, is opened in the mounting groove 14 of the fixed seat 13 away from the first circular through hole 12 side, rotates and is installed in the screw disk 15 in the mounting groove 14, along The fixing seat 13 is evenly distributed in the circumferential direction on the three slide grooves 16 on the side of the fixing seat 13 close to the first circular through hole 12 , and the slider 17 is slidably disposed in the slide groove 16 along the radial direction of the fixing seat 13 . Three first strip-shaped through-holes 18 are evenly distributed along the circumference of the box body 1 on the side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com