Large-diameter steel pipe butt-joint auxiliary connection tool

A large-diameter, steel pipe technology, applied in the field of steel structure mechanical construction auxiliary tools, can solve problems such as low precision, unreasonable docking methods, and non-versatile docking tools, etc., achieve low production costs, and facilitate batch industrial processing and manufacturing , good practical value and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

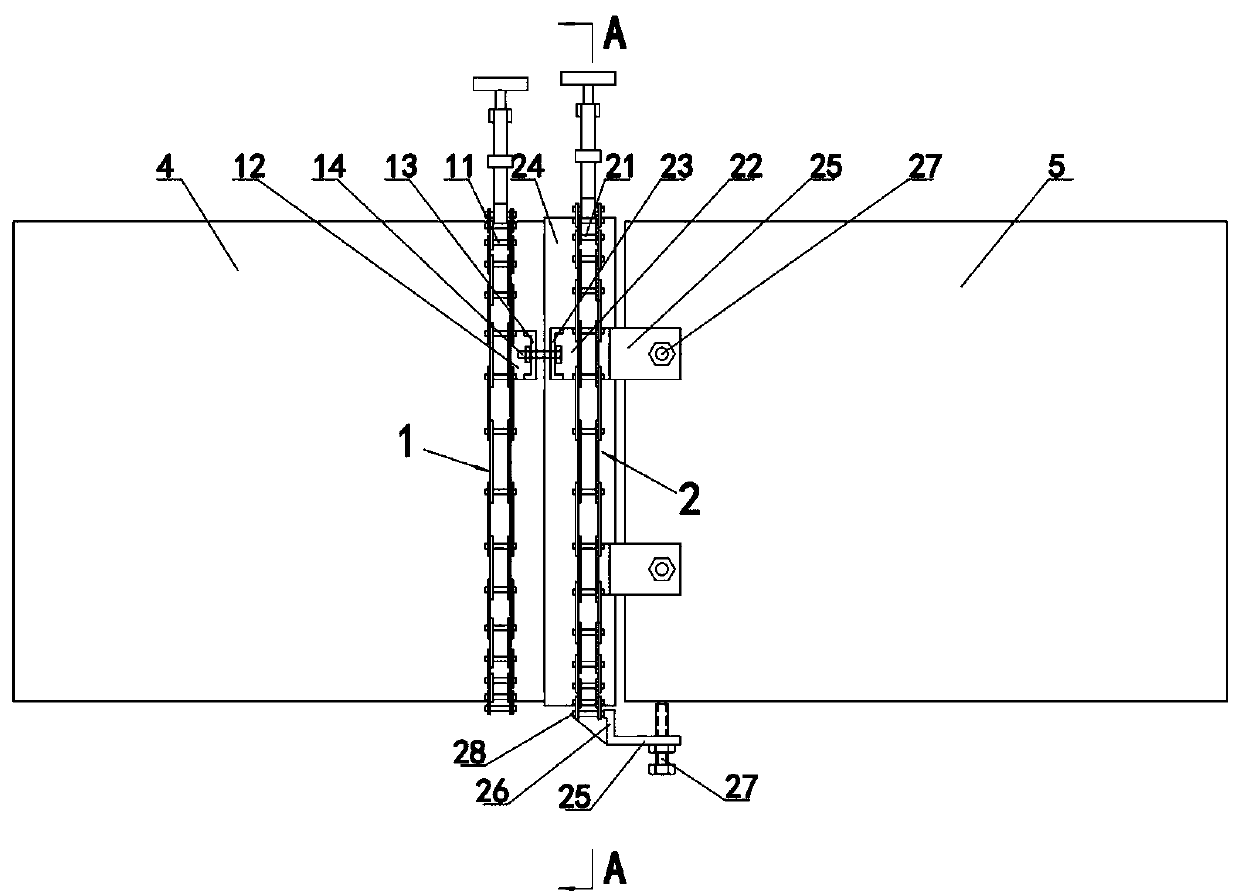

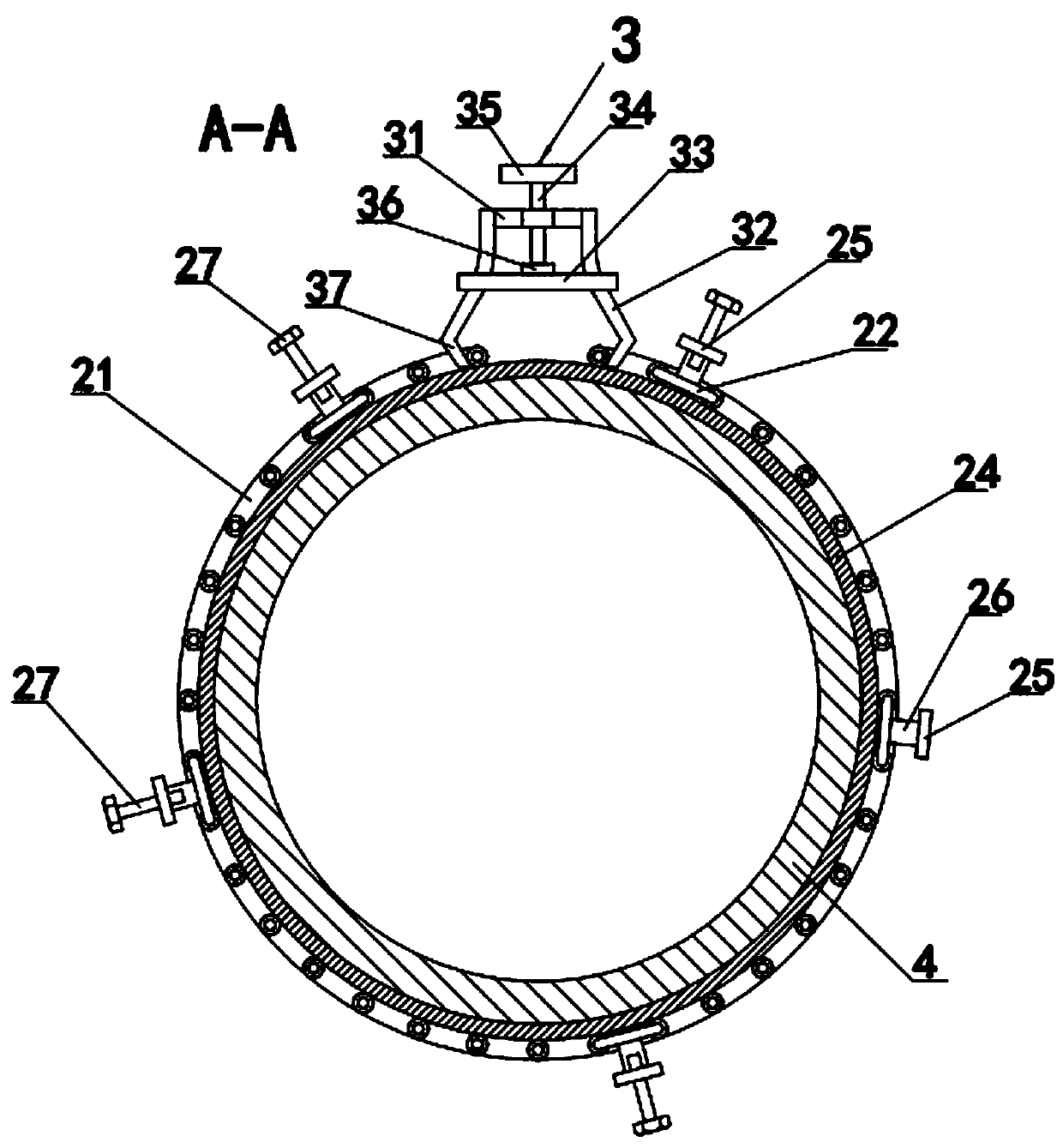

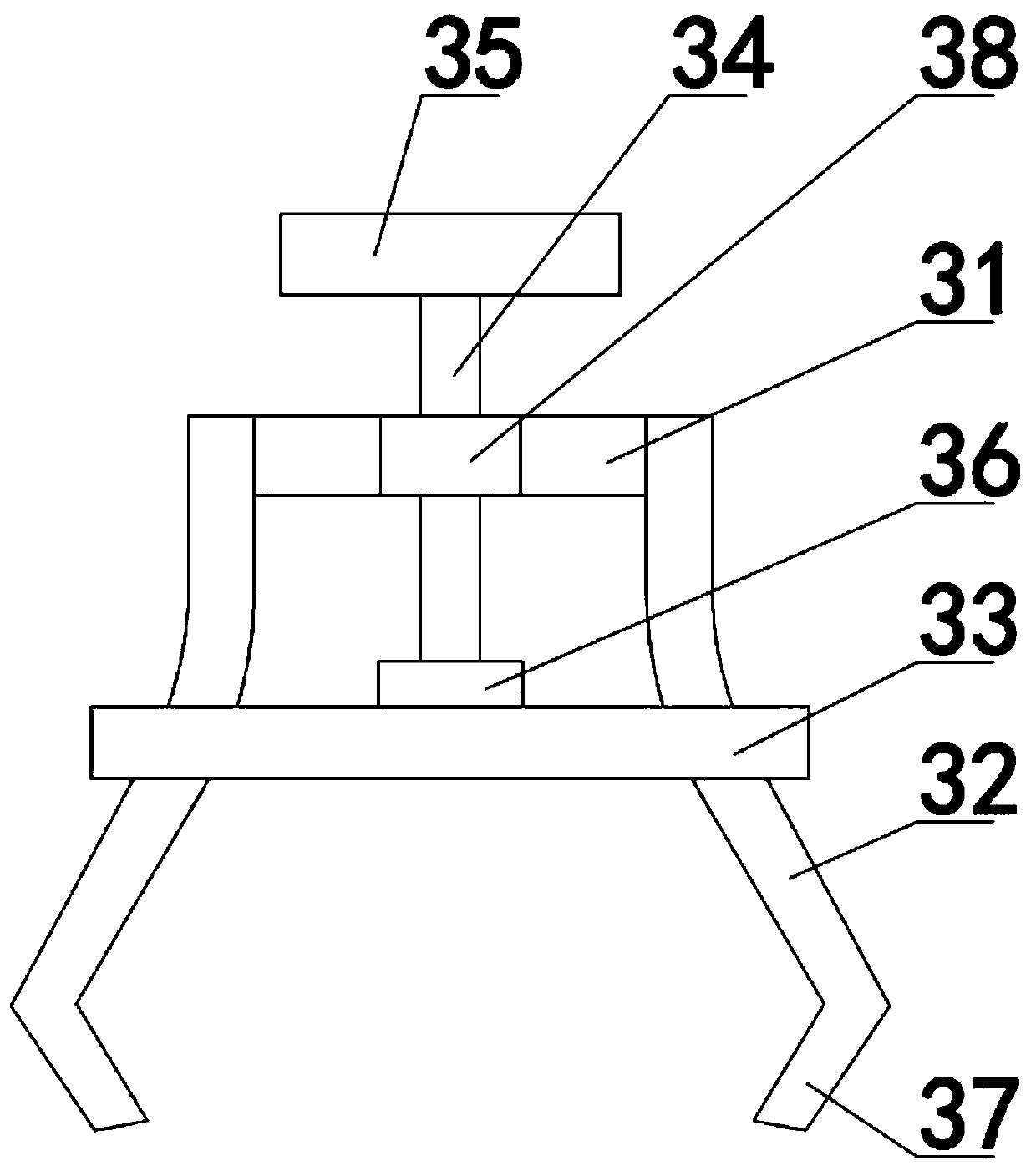

[0020] Embodiment 1: as figure 1 When the connecting tool is applied to the butt joint of large-diameter steel pipes, the tool only needs to be assembled on the fixed cylindrical steel pipe at first, and then the free cylindrical steel pipe and the fixed cylindrical steel pipe are docked and fixed when the welding operation is required. It is mainly used as an auxiliary tool for welding or kit construction after the ends of large-diameter steel pipes are accurately butt-jointed. And it can be applied to some emergency fields, such as alignment welding after pipeline rupture. When this tool is applied to the workshop to implement the butt joint of two equal-diameter or different-diameter steel pipes, it can also achieve fast and accurate butt joint effects. The tool mainly includes four main components including a fixed lock piece, a movable lock piece and two locking devices. The fixed lock, the movable lock and the locking device are independently assembled components. For ...

Embodiment 2

[0026] Embodiment 2: On the basis of Embodiment 1, the form of the sliding sleeve can be changed. The sliding sleeve adopted in embodiment 1 is a closed cylinder sliding sleeve, while the sliding sleeve used in this embodiment has a semi-closed sliding sleeve with cracks on the circumferential side. When the semi-closed sliding sleeve is used, upwardly protruding flanges are respectively provided on the two ends of the crack, and connecting holes are respectively arranged on the flanges, and connecting bolts run through the connecting holes.

Embodiment 3

[0027] Embodiment 3: On the basis of Embodiment 1, arc-shaped spacers are fixed on the bottom surface of some or all of the chain links of the fixed chain or movable chain, and each arc-shaped spacer is approximately consistent with the arc of the side wall of the cylindrical tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com