Cascading damping and rotation parallel structure

A technology of damping rotation and parallel connection, which is applied in precision positioning equipment, belts/chains/gears, mechanical equipment, etc. It can solve the problems that the existing structure cannot meet the requirements, and achieve good scalability, integration, and scientific and efficient design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

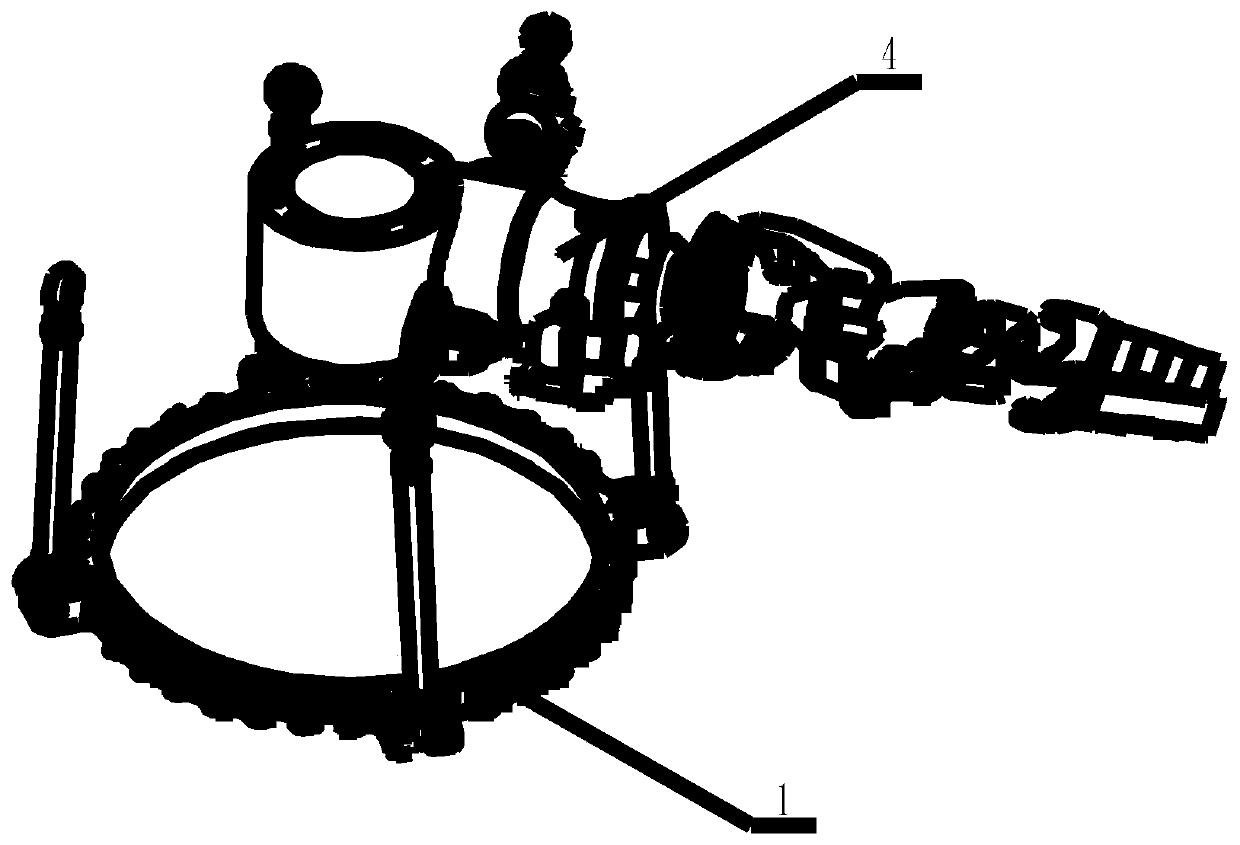

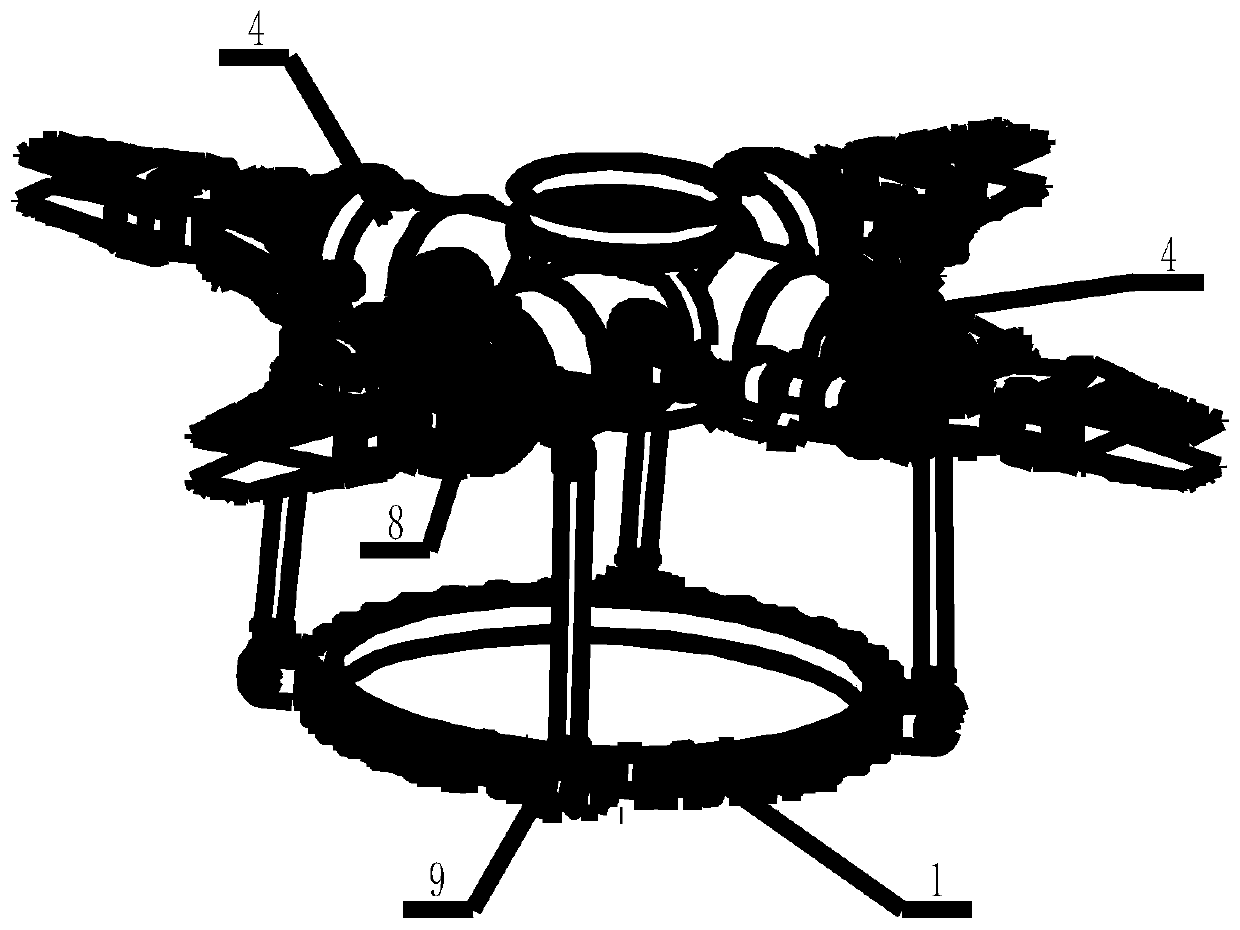

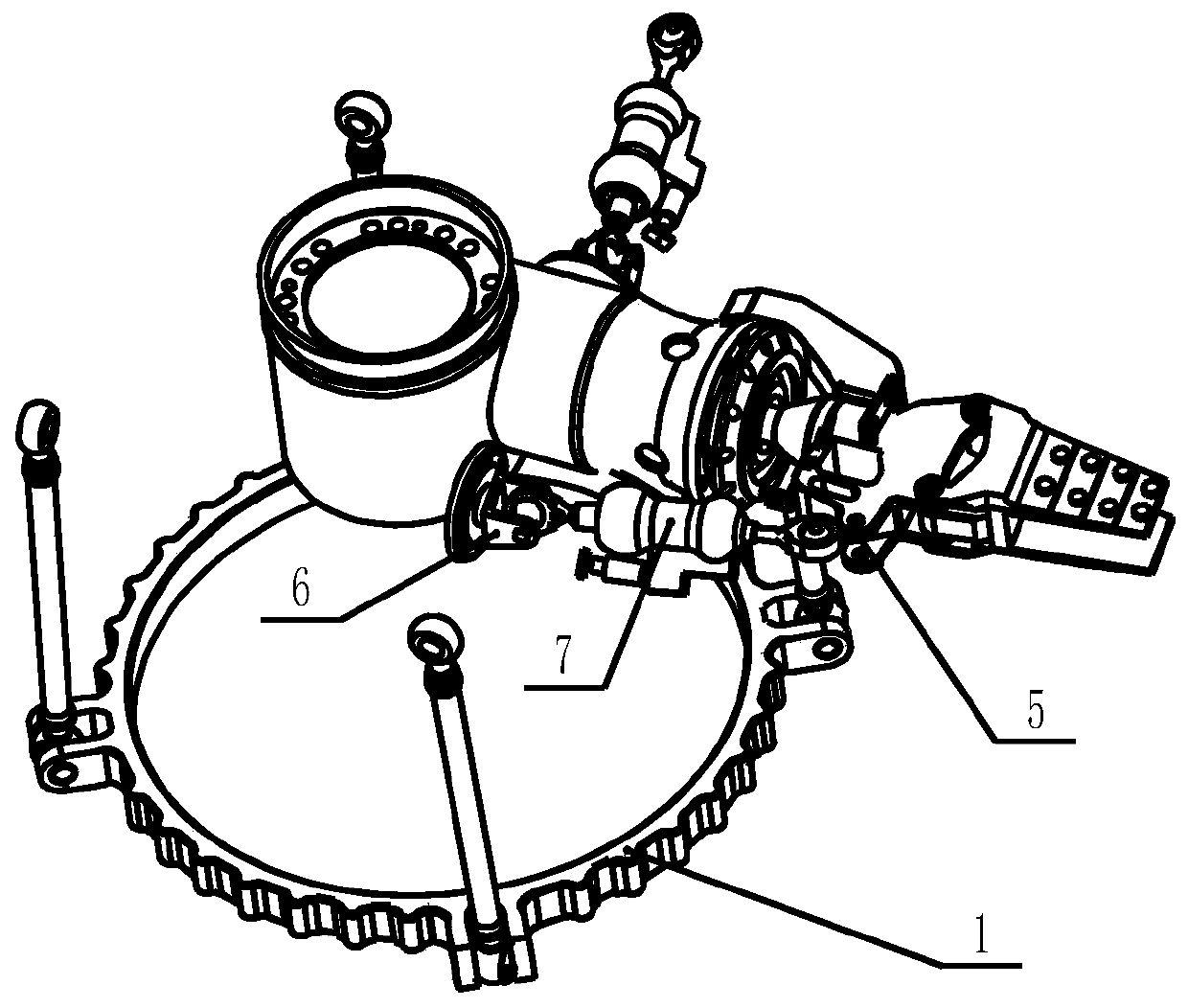

[0022] According to the attached Figure 1-7 The present invention is described further:

[0023] A cascade damping rotary parallel structure is provided, including a driven plate 1 and a driving plate 2 arranged up and down, the driven plate and the driving plate are linked through the transmission shaft 3, and the transmission shaft is equipped with a transmission A sleeve, on which a plurality of transmission arms 4 are evenly equipped in the radial direction;

[0024] The transmission arm is composed of a rotating arm shaft seat, a rotating shaft, a balance piece, and a follower. The rotating arm shaft seat is fitted and fixed on the transmission sleeve along the radial direction. The outlet end is connected with the balance piece, one side of the balance piece has two active bumps 5 protruding to one side, and the other side of the balance piece has a protruding crutch seat 8, and the head of the balance piece is hinged with a follower The moving part, one side of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com