Quick connecting structure of pipefitting

A technology for connecting structures and pipe fittings, which is applied in the direction of mechanical equipment, couplings, etc., can solve the problems of inability to adapt to pipe fittings, cannot rotate and twist, cumbersome operation, bulky volume, etc., and achieves the effects of small space occupation, simple operation, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

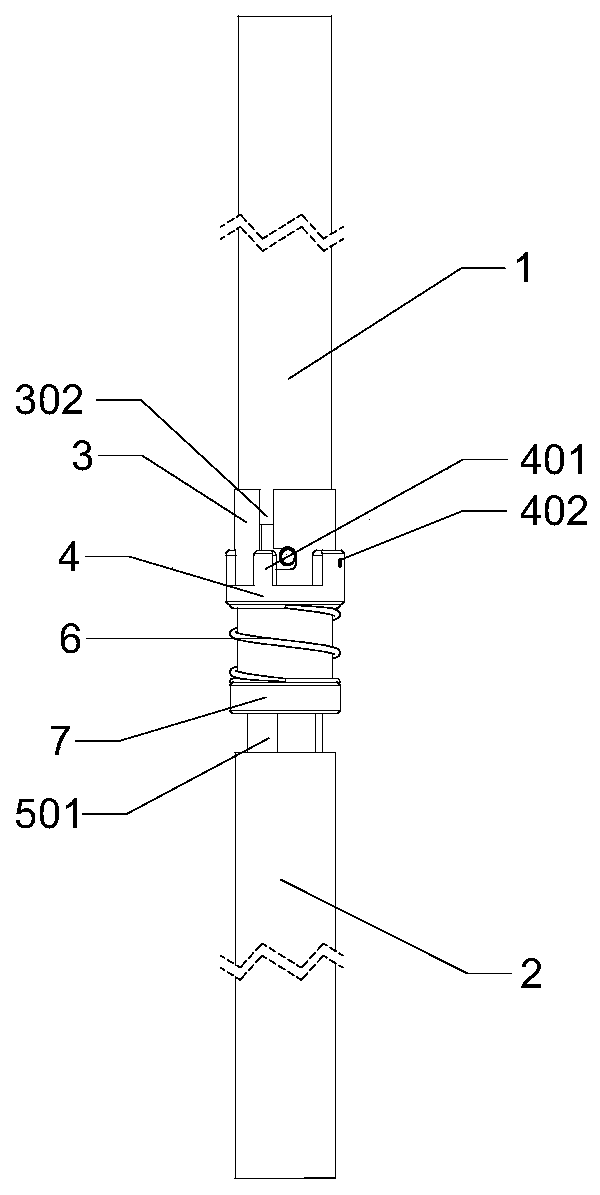

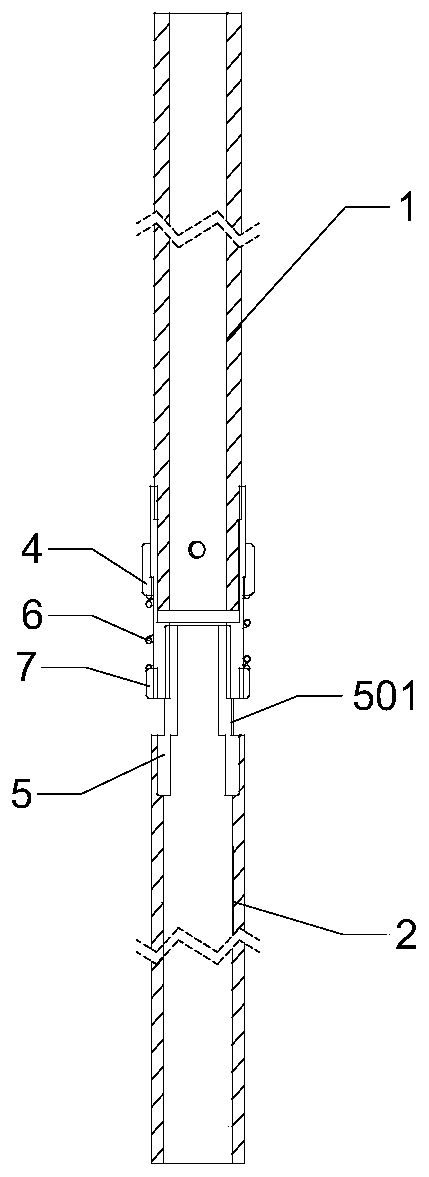

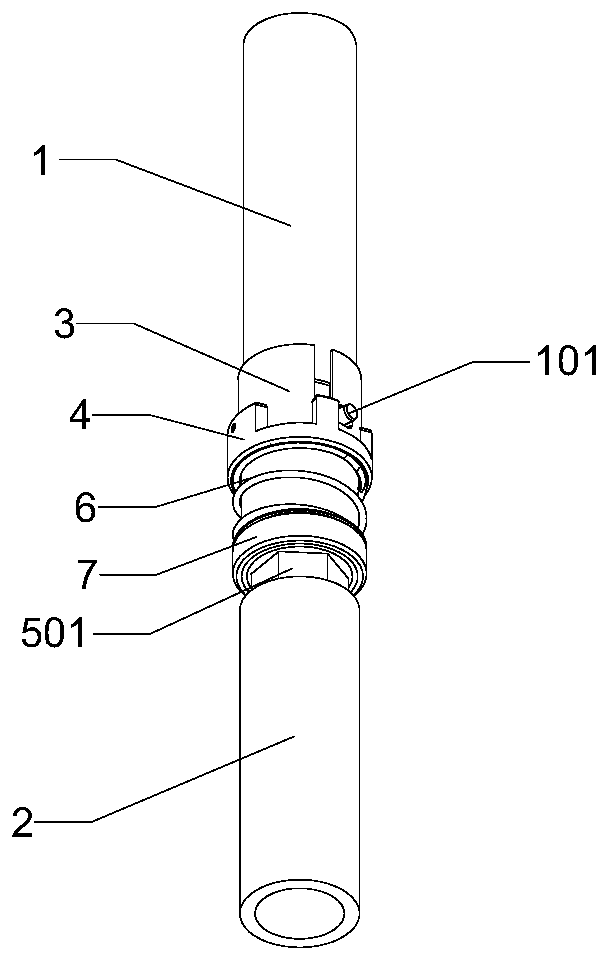

[0031] Such as Figure 1-5 As shown, the present invention is a quick connection structure of pipe fittings, which connects the upper pipe 1 and the lower pipe 2. The part of the upper pipe 1 used for connection is also provided with a raised stud 101, including a slot sleeve 3 and a snap ring 4 And the connection sleeve 5, one end of the connection sleeve 5 is connected with the lower pipe 2, the other end of the connection sleeve 5 is connected with the slot cover 3, the slot cover 3 is provided with a slot 301 and a notch groove 302, the slot cover 3 Through the notch groove 302 and the protruding stud 101 of the upper tube 1, the snap ring 4 is sleeved outside the snap ring 4, and a limit block 401 is also arranged on the snap ring 4, and the snap ring 4 passes through the clip. The slot 301 and the snap ring 4 are fixed in cooperation with each other, and the snap ring 4 limits the protruding stud 101 of the upper tube 1 in the notch slot 302 through the stop block 401 . ...

Embodiment 2

[0034] This embodiment is a further description of the present invention.

[0035] Such as Figure 1-3 As shown, this embodiment is based on Embodiment 1. In a preferred embodiment of the present invention, a spring 6 and a spring retaining ring 7 are also sleeved on the periphery of the card slot sleeve 3, and the spring retaining ring 7 is fixed On the slot sleeve 3 , the spring 6 is arranged between the retaining ring 7 and the snap ring 4 , and the spring 6 abuts against the snap ring 4 . With the above-mentioned structure, the lower end of the spring 6 is positioned and blocked by the retaining ring 7, so that the protruding stud 101 of the upper tube 1 enters from the notch groove 302, and the snap ring 4 moves down along the groove sleeve 3, compressing the spring 6, and After the protruding stud 101 of the tube 1 snaps into the bottom of the notch groove 302, the snap ring 4 will rebound and lock the protruding stud 101 of the upper tube 1 under the action of the spring...

Embodiment 3

[0037] This embodiment is a further description of the present invention.

[0038] This embodiment is based on the above embodiments, and in a preferred embodiment of the present invention, a positioning block 501 is also provided in the middle of the connecting sleeve 5 . With the above-mentioned structure, the positioning block 501 is used to separate the two ends of the connection sleeve 5 and connect with the down tube 2 and the groove sleeve 3 respectively.

[0039] In a preferred embodiment of the present invention, both ends of the connecting sleeve 5 are provided with threads, one end of the connecting sleeve 5 is threaded with the lower pipe 2, and the other end of the connecting sleeve 5 is threaded with the slot sleeve 3 . With the above structure, through the thread pre-connection of the connecting sleeve 5 and the lower pipe 2, it is only necessary to rotate the connecting sleeve 5 without rotating the lower pipe 2; the other end of the connecting sleeve 5 is thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com