Coal conveying metering system and method

A measurement system and coal transportation technology, applied in radio wave measurement system, weighing, calculation, etc., can solve the problems of untimely information communication, breeding of cheating, property loss of coal mines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

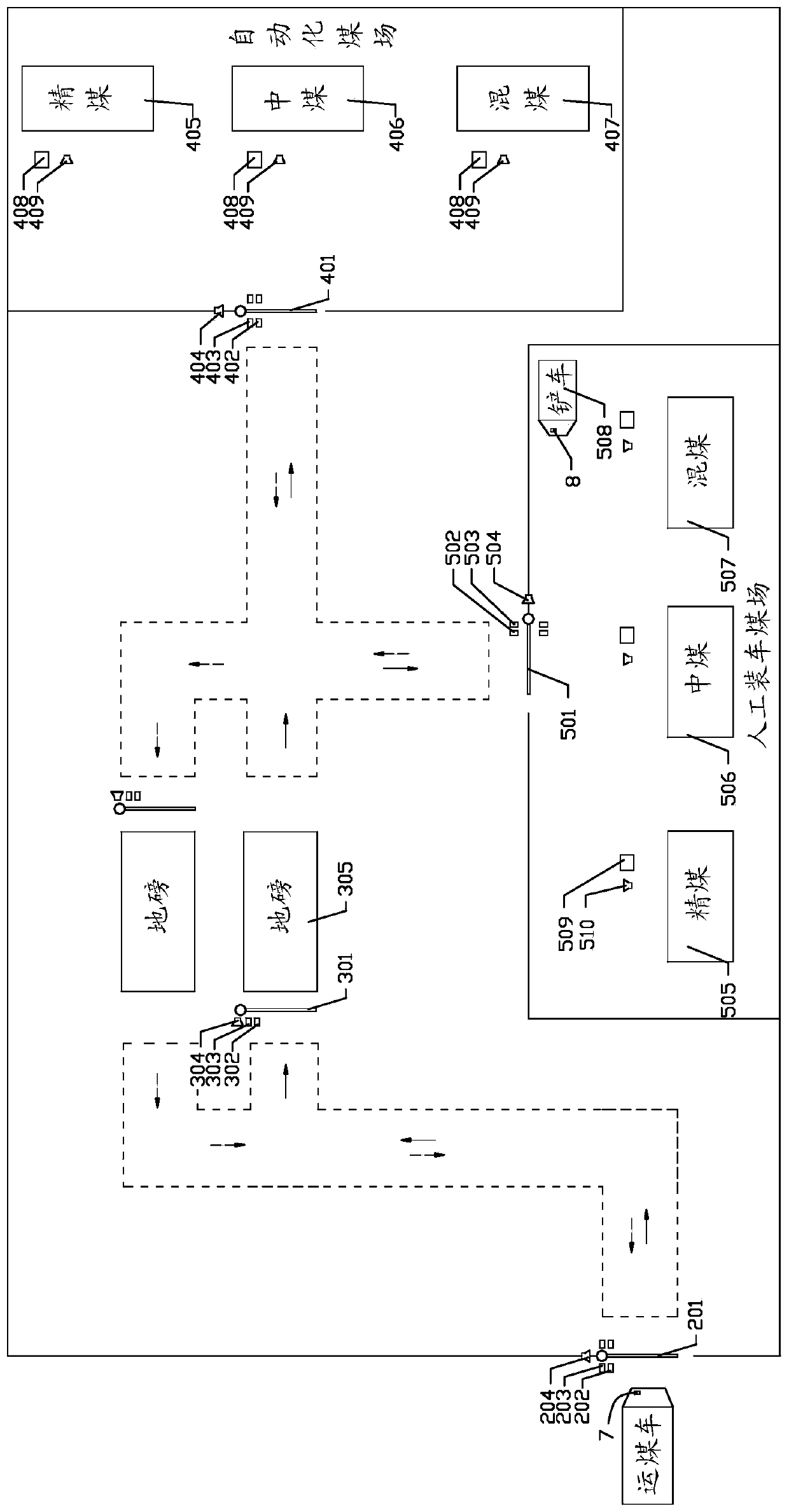

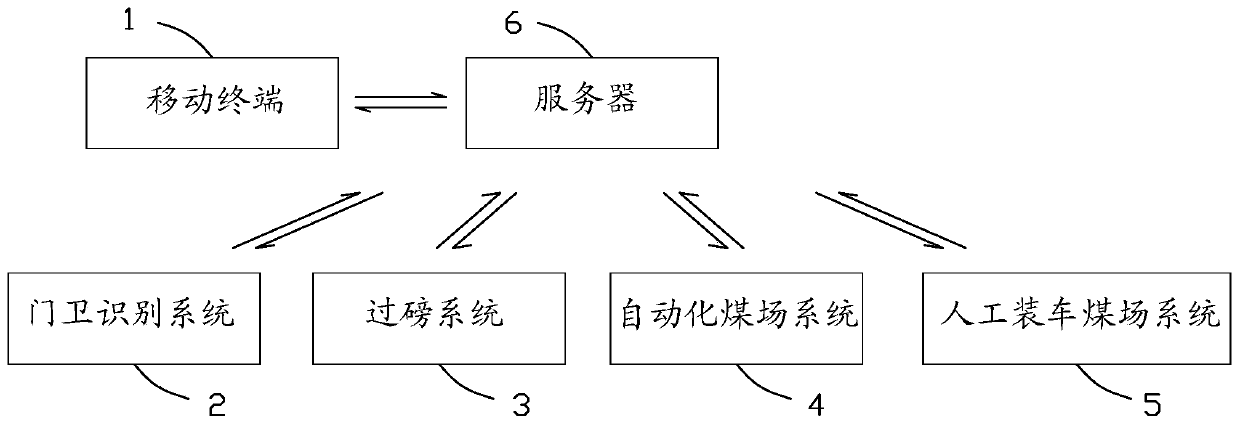

[0119] Such as figure 1 and figure 2 As shown, a coal delivery metering system includes a mobile terminal 1 , a doorman identification system 2 , a weighbridge system 3 , an automated coal yard system 4 , a manual loading coal yard system 5 and a server 6 .

[0120] The mobile terminal 1 is, for example, a mobile phone, a PAD, etc., and is used to collect task information including basic driver information, vehicle information, unit information of the vehicle, and transport coal type, and upload the task information to the server 6 .

[0121] When the task information needs to be updated, the mobile terminal APP is used to modify and upload to the server 6.

[0122] Among them, the vehicle information includes license plate information, size information, etc., and the types of coal to be transported include clean coal, medium coal, and mixed coal.

[0123] The above task information is also recorded in the two-dimensional code 7 .

[0124] The QR code 7 for recording task ...

Embodiment 2

[0224] This embodiment 2 describes a coal delivery metering method, which is based on the coal delivery metering system in the above-mentioned example 1. Through the coal delivery metering method, it is beneficial to realize automatic monitoring of the entire process of coal delivery metering operations in coal mines.

[0225] Such as Figure 6 As shown, a coal delivery metering method comprises the following steps:

[0226] s1. When the coal truck arrives at the No. 1 barrier 201, the No. 1 video collection device 202 collects the license plate information of the coal truck, and the No. 1 code scanning device 203 collects the QR code at the front glass window of the coal truck information.

[0227] No. 1 video collection device 202 and No. 1 code scanning device 203 upload the collected information to the server 6 .

[0228] The server 6 compares whether the license plate collected by the No. 1 video collection device 202 matches the vehicle information collected by the No....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com