Material preparation device for loader test platform

A test platform and loader technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve problems such as difficult to meet the requirements of shovel loading experiments and narrow application fields, so as to improve convenience and applicability , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

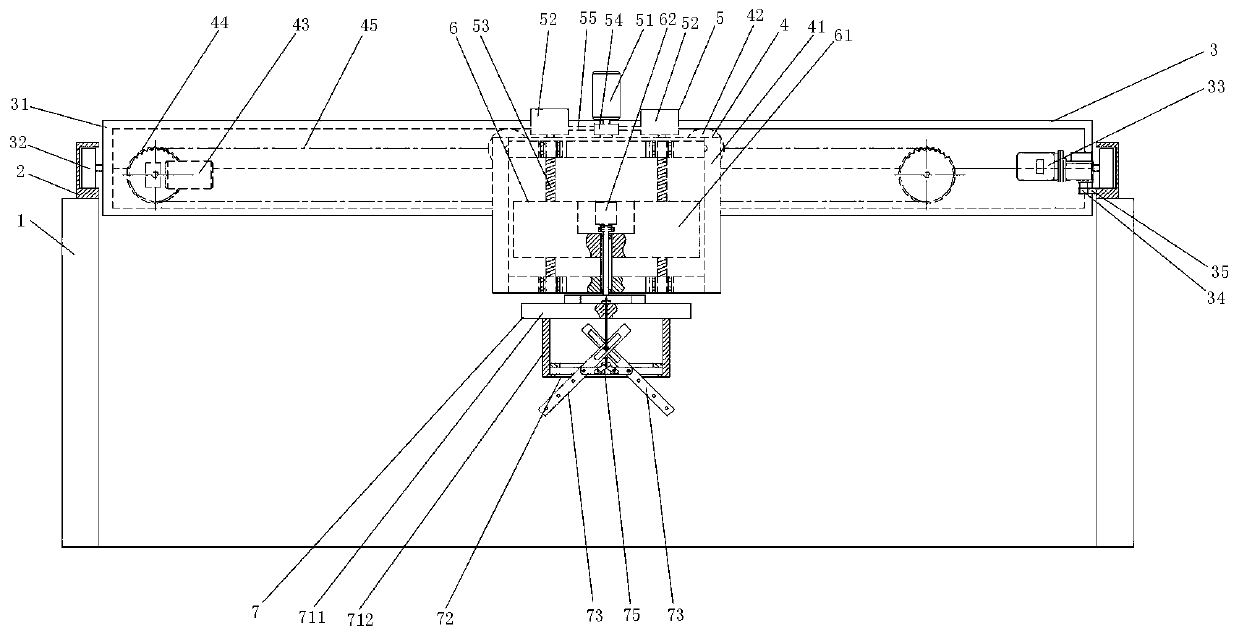

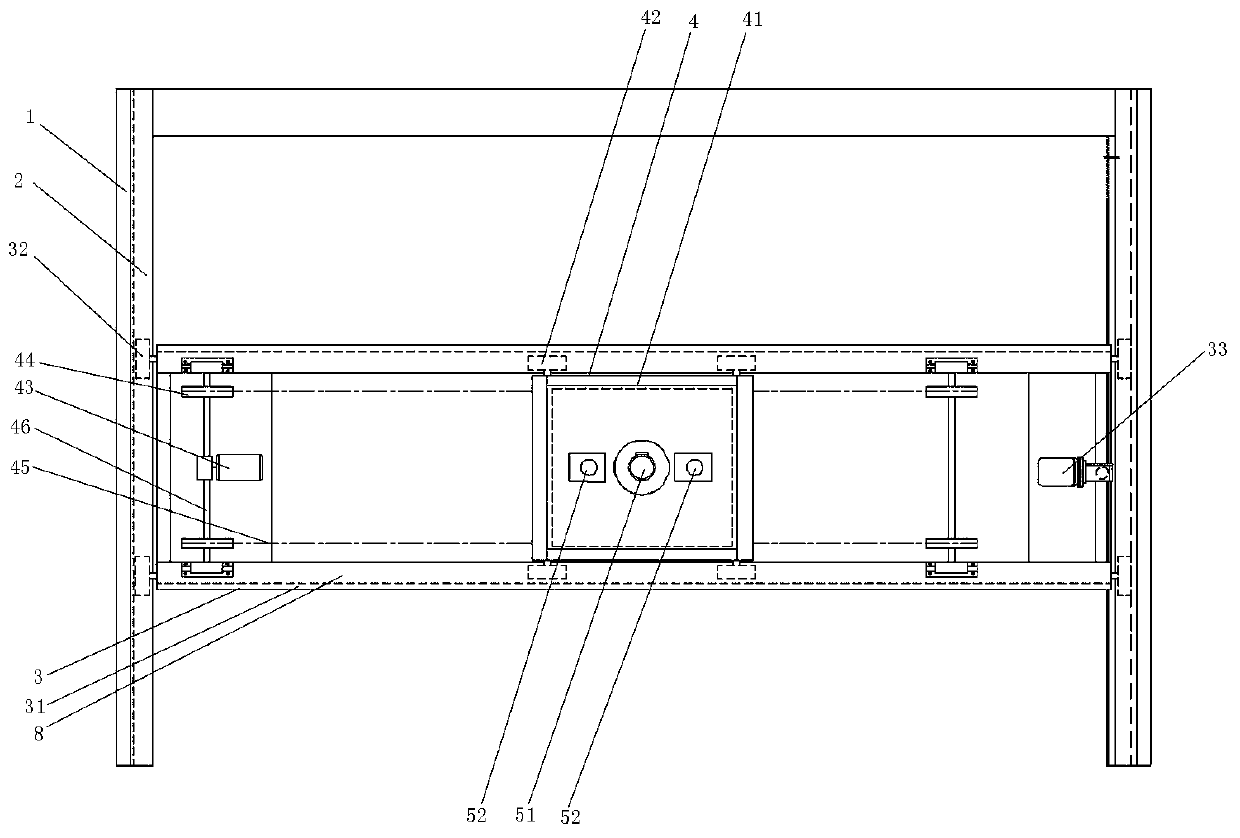

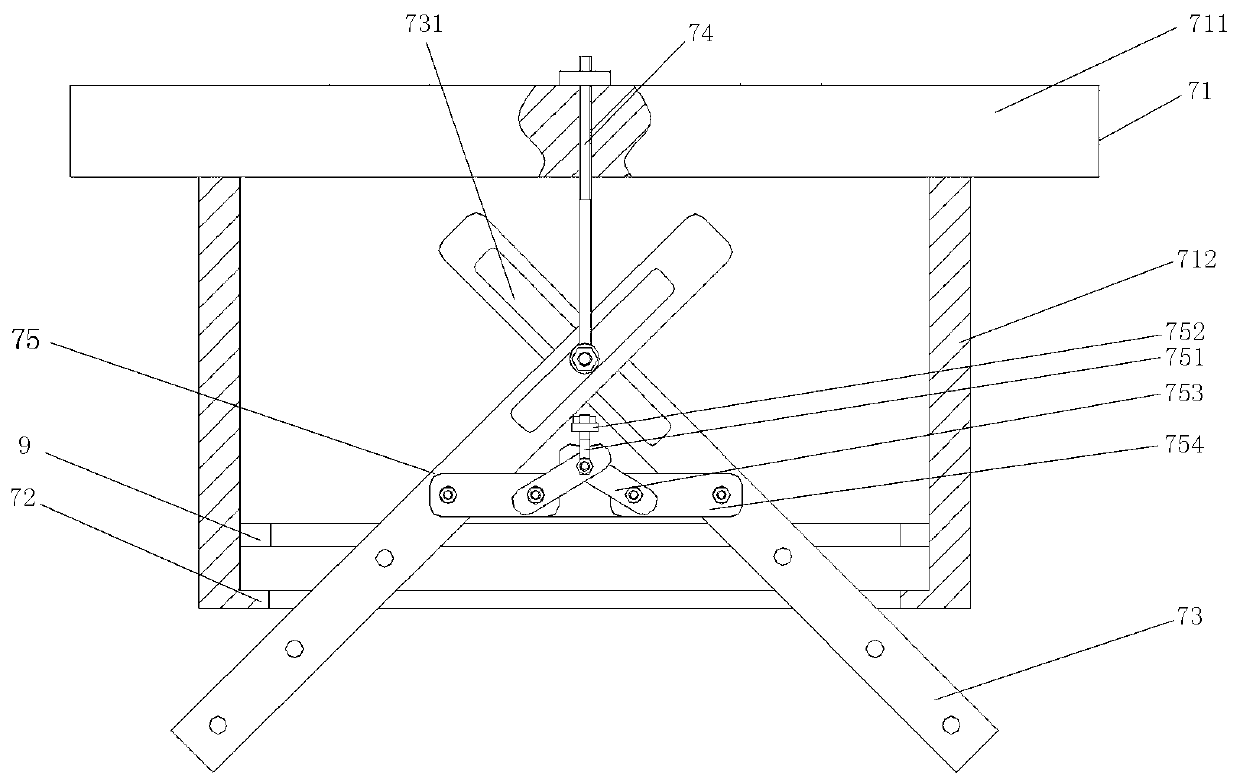

[0038] Such as Figure 1-3 As shown, the material preparation device facing the loader test platform provided in this embodiment includes a support frame 1, a guide groove 2, a moving beam 3, an X-direction moving device 4, a Z-direction moving device 5, a rotating device 6, and a preparation mechanism 7 ;

[0039] Described support frame 1 is a square frame, is provided with two, is respectively positioned at the both sides of the X direction of loader test bench, and two support frames 1 extend along Y direction respectively; Described guide groove 2 is provided with two, The two guide grooves 2 are arranged along the Y direction of the loader test bench; the moving beam 3 is arranged along the X direction, and its two ends are installed on two On the guide groove 2, it can move upward in Y along the guide groove 2;

[0040] The moving beam 3 is provided with a guide rail 8 parallel to it, and the X-direction moving device 4 is installed on the guide rail 8 and can move in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com