Eccentricity Control Method for Mass Production of Cemented Lenses

A cemented lens, mass production technology, applied in the direction of instruments, installation, optics, etc., can solve the problems of low production efficiency, poor eccentricity, poor stability of lens eccentricity, etc., achieve the effect of reducing the number of times, improving the pass rate, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

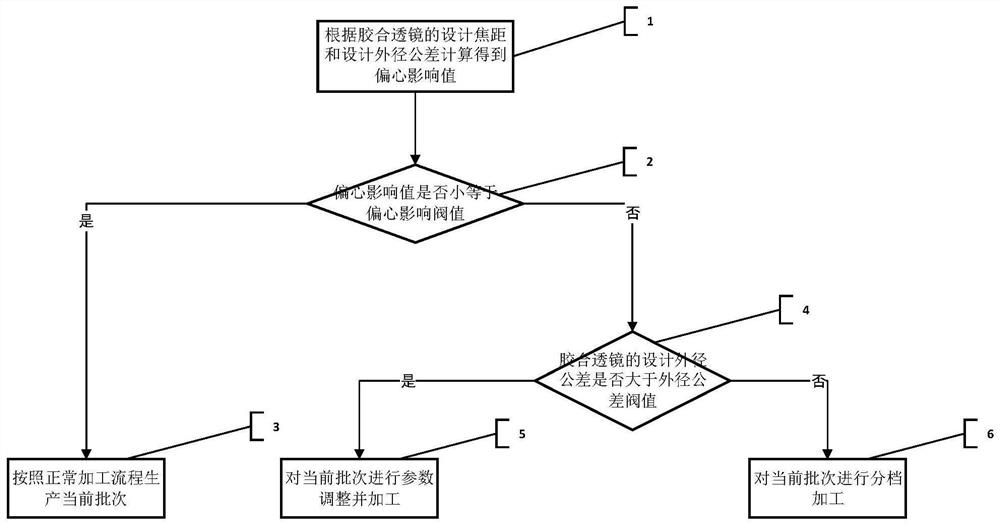

[0063] Embodiment 1: the design focal length of the cemented lens is 40 millimeters, and the design outer diameter tolerance is 0.01 millimeter, then adopt the eccentricity control method of the mass production of the cemented lens of the present application. The specific steps include:

[0064] Step 1. According to the design focal length of the cemented lens (40 mm) and the design outer diameter tolerance (0.01 mm), the eccentricity influence value is calculated to be equal to 0.86 points, and the calculation formula is: Among them, C is the influence value of eccentricity, f is the design focal length value of the cemented lens, and ΔD is the design outer diameter tolerance value of the cemented lens;

[0065] Step 2, judging whether the eccentricity impact value of 0.86 is less than or equal to the eccentricity impact threshold of 1 point;

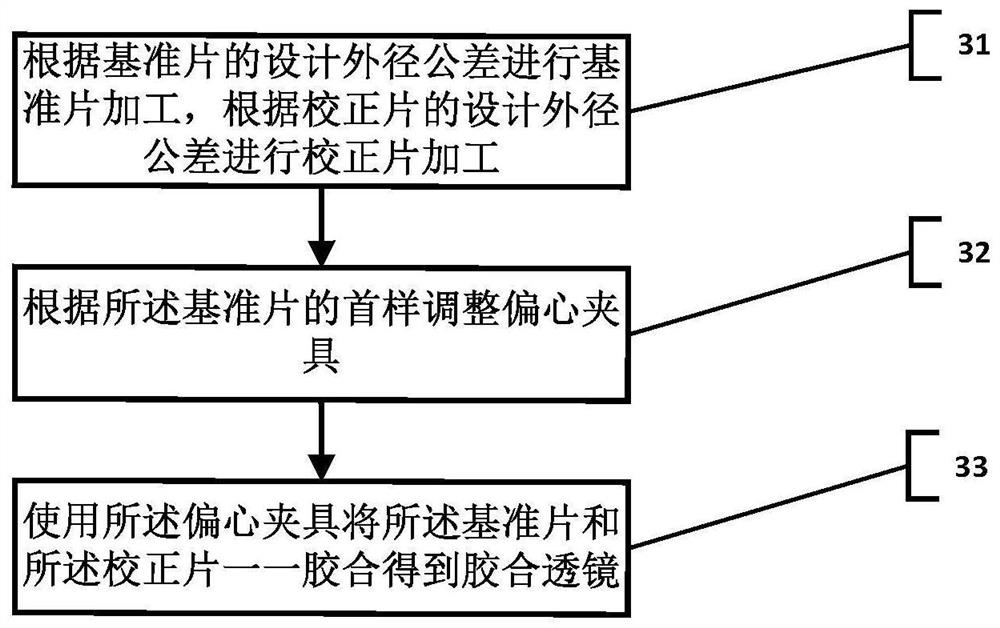

[0066] Step 3. If the eccentricity impact value of 0.86 points is less than the eccentricity impact threshold value of 0.1 points, i...

Embodiment 2

[0068] Embodiment 2: the design focal length of the cemented lens is 40 millimeters, and the design outer diameter tolerance is 0.02 millimeters, then adopt the eccentric control method of the mass production of the cemented lens of the present application and the specific steps include:

[0069] Step 1. According to the design focal length of the cemented lens (40 mm) and the design outer diameter tolerance (0.02 mm), the eccentricity influence value is calculated to be 1.72 points, and the calculation formula is: Among them, C is the influence value of eccentricity, f is the design focal length value of the cemented lens, and ΔD is the design outer diameter tolerance value of the cemented lens;

[0070] Step 2, judging whether the eccentricity impact value of 1.72 is less than or equal to the eccentricity impact threshold of 1 point;

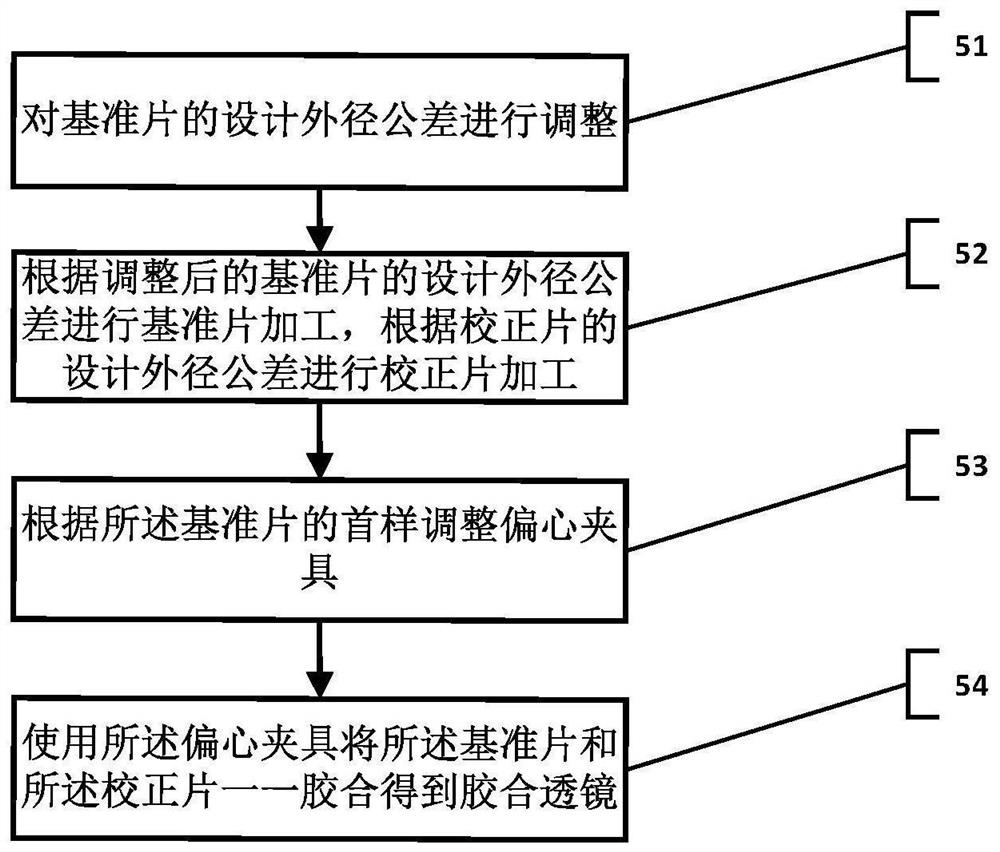

[0071] Step 4, if the current eccentricity influence value of 1.72 points is greater than the eccentricity influence threshold value of 1 po...

Embodiment 3

[0077] Embodiment 3: the design focal length of the cemented lens is 30 millimeters, and the design outer diameter tolerance is 0.01 millimeter, then adopt the eccentric control method of the mass production of the cemented lens of the present application and the specific steps include:

[0078] Step 1. According to the design focal length of the cemented lens (30 mm) and the design outer diameter tolerance (0.01 mm), calculate the eccentricity influence value of 1.15 points, and the calculation formula is: Among them, C is the influence value of eccentricity, f is the design focal length value of the cemented lens, and ΔD is the design outer diameter tolerance value of the cemented lens;

[0079] Step 2, judging whether the eccentricity impact value of 1.15 is less than or equal to the eccentricity impact threshold of 1 point;

[0080] Step 4, if the current eccentricity influence value of 1.15 points is greater than the eccentricity influence threshold value of 1 point, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com