Distribution automation terminal intelligent power supply device and battery evaluation method

A technology of distribution automation and intelligent power supply, applied in battery circuit devices, circuit devices, measuring devices, etc., can solve the problems of unfavorable distribution automation terminals working normally, single battery management function, and no function of recording events, etc. Intelligent battery switching management, realizing the effect of voltage under-voltage management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

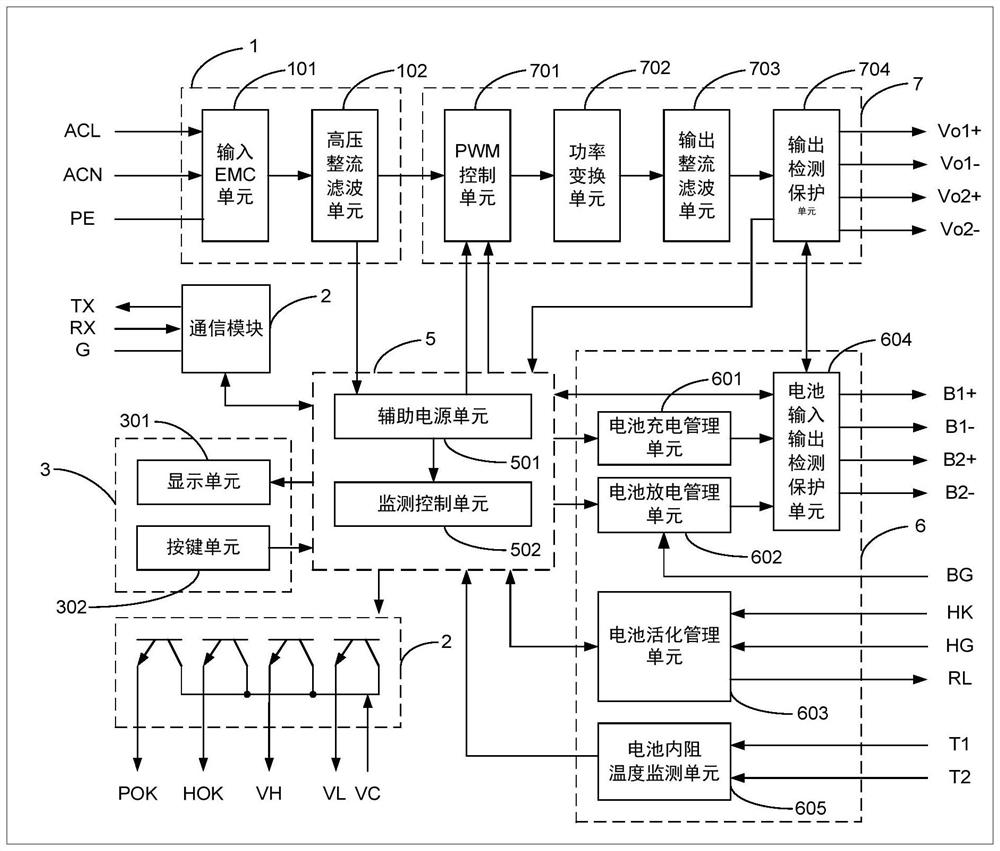

[0050] Such as figure 1 As shown, this embodiment provides a distribution automation terminal intelligent power supply device, the device includes an AC input module 1, a communication module 2, a display module 3, an alarm module 4, a monitoring control module 5, a battery management module 6 and a power output Module 7 and monitoring control module 5 are respectively connected with AC input module 1, communication module 2, display module 3, alarm module 4, battery management module 6, and power output module 7, and power output module 7 is respectively connected with AC input module 1 and battery management The modules 6 are connected, and the AC input module 1, the communication module 2, the alarm module 3, the battery management module 6 and the power output module 7 are all externally connected with wiring ports.

[0051] Described AC input module 1 comprises input EMC (Electro Magnetic compatibility, electromagnetic compatibility) unit 101 and high-voltage filter recti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com