Liquid extraction system and extraction method

A liquid extraction and liquid outlet pipe technology, which is applied in separation methods, chemical instruments and methods, sedimentation tanks, etc., can solve the problems of difficult liquid extraction operations, easy to bring in sedimentation dregs, and impure liquid extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

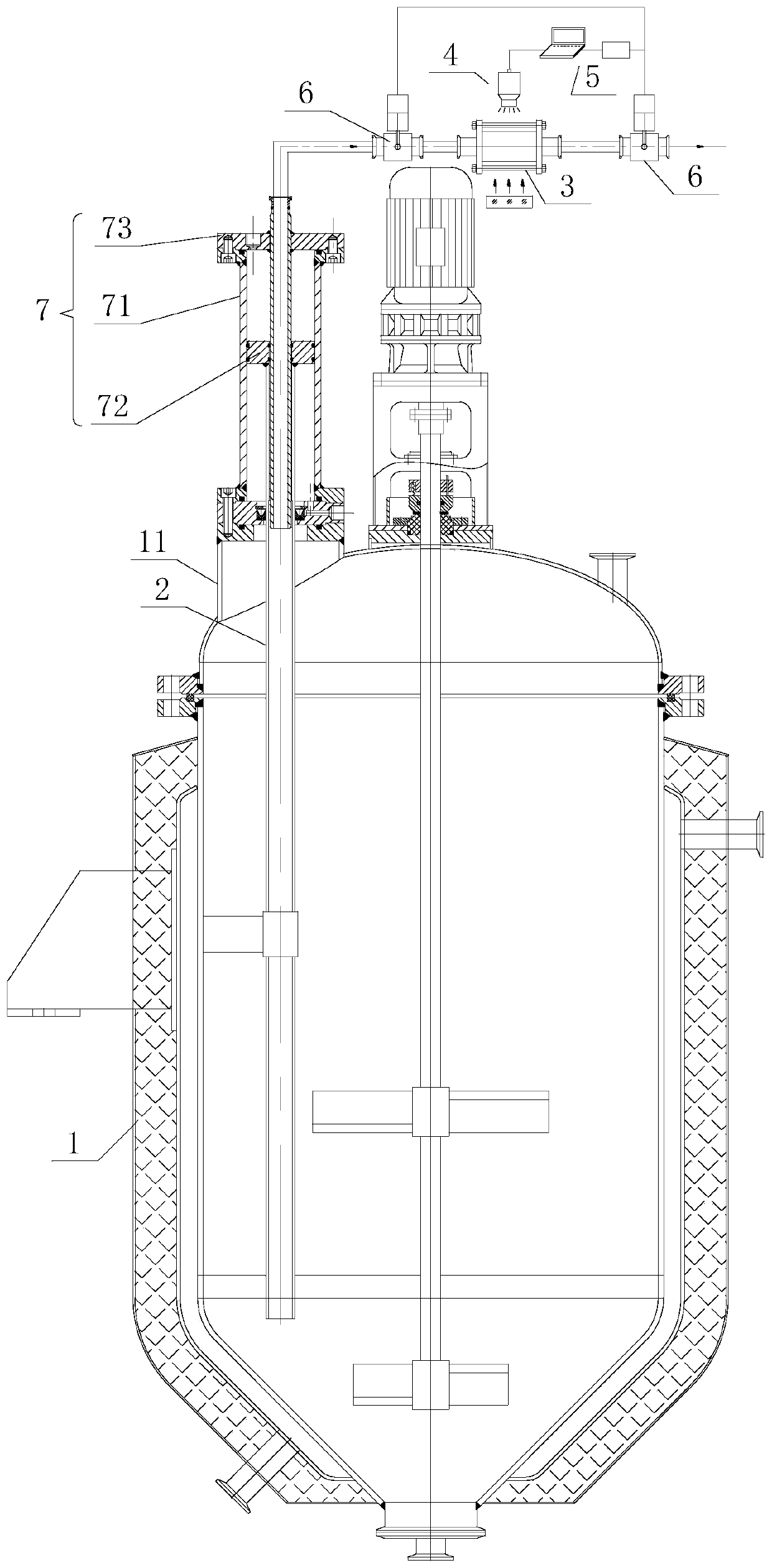

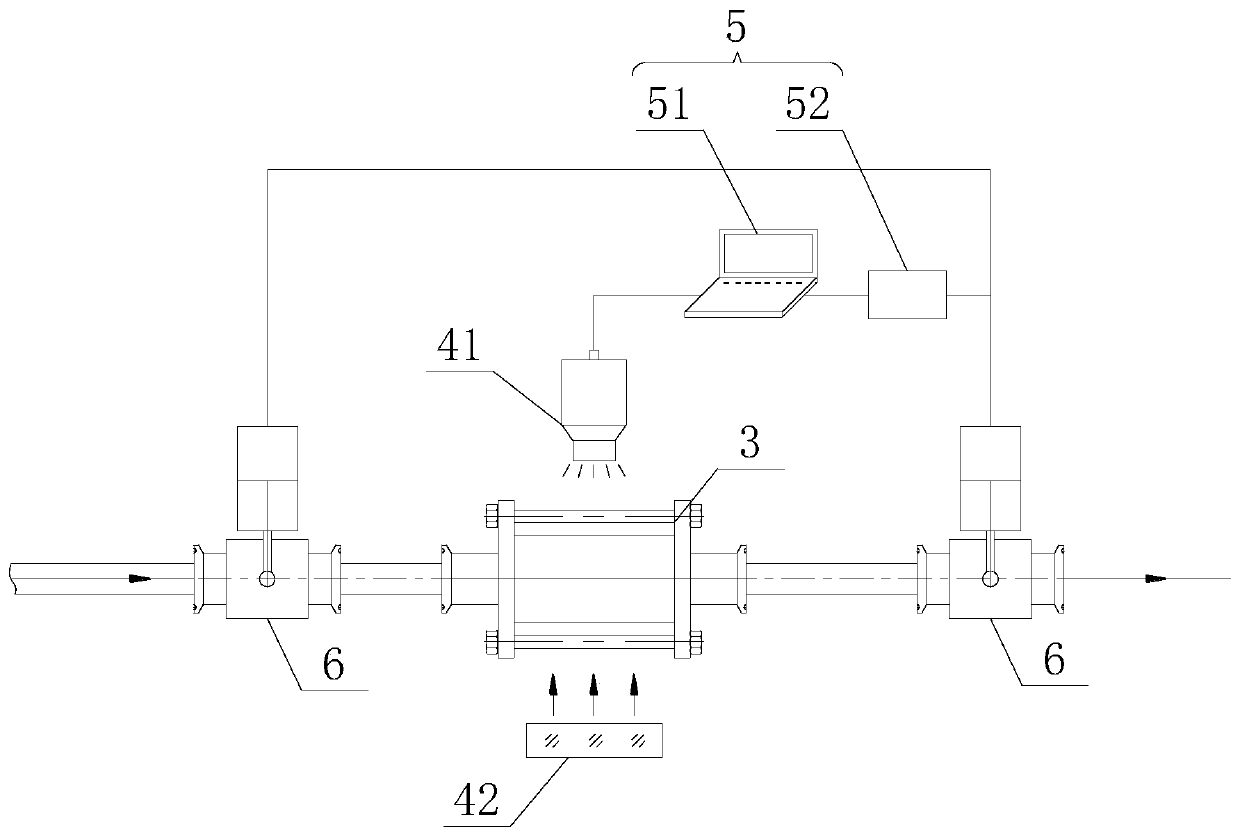

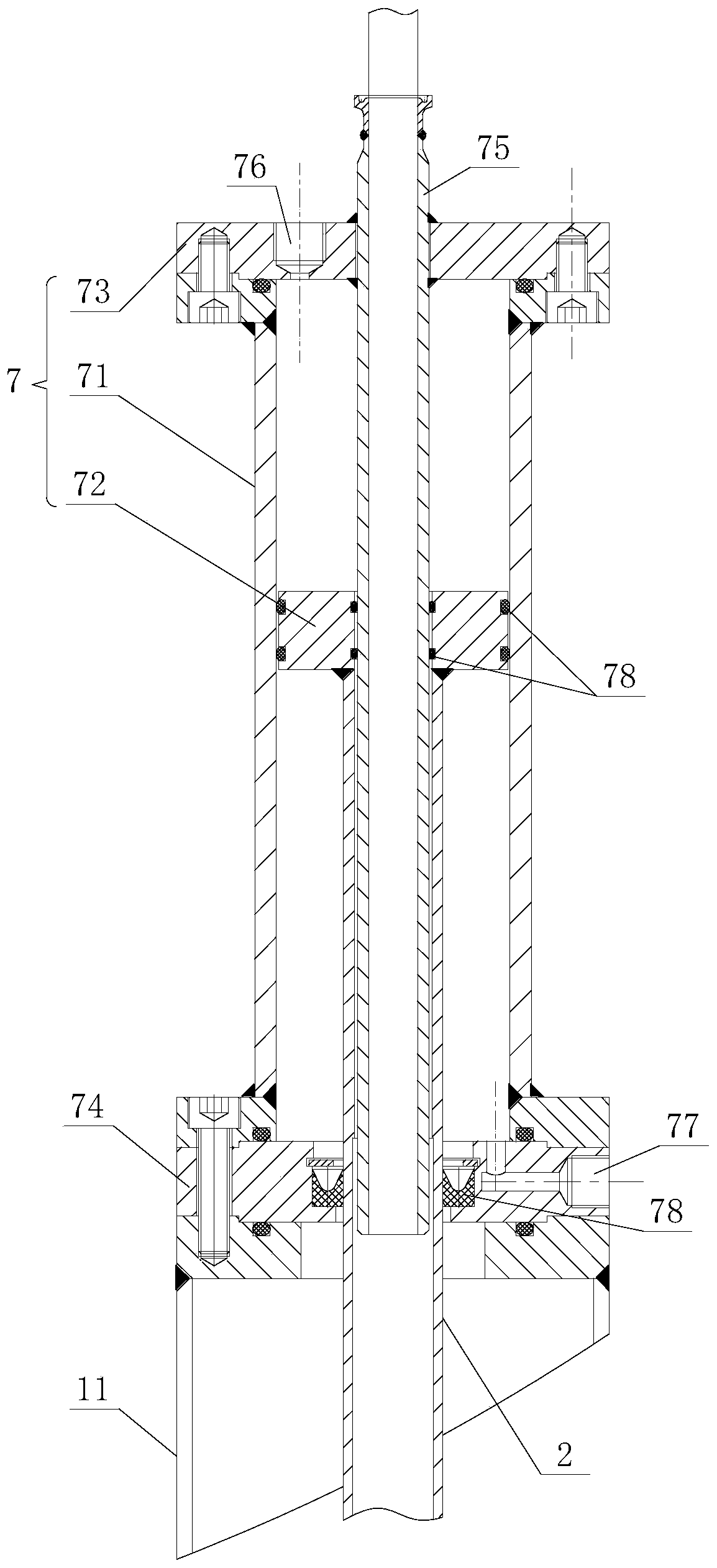

[0029] Figure 1 to Figure 3 An embodiment of the liquid extraction system of the present invention is shown. The liquid extraction system includes a settling tank 1 for solid-liquid separation. The settling tank 1 is provided with a lifting liquid outlet pipe 2 that can be lifted. The liquid extraction system also includes a permeable Optical pipeline sight mirror 3, an image acquisition and recognition device for taking pictures and identifying materials flowing through the light-transmitting pipeline sight mirror 3, and an electrical control device for receiving the identification signal of the image acquisition and identification device 4 and sending a valve closing signal 5 and the control valve 6 for receiving the valve closing signal command from the electrical control device 5, one end of the lifting liquid outlet pipe 2 exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com