Vertical copper phthalocyanine synthesis reaction kettle feeding structure and reaction kettle

A synthesis reaction, copper phthalocyanine technology, applied in the field of feeding structure of the reaction vessel, can solve the problems that the feeding cannot continue, the material spills out of the kettle, and the gas overflows, so as to avoid waste and unevenness, reduce environmental pollution, The effect of liberating labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

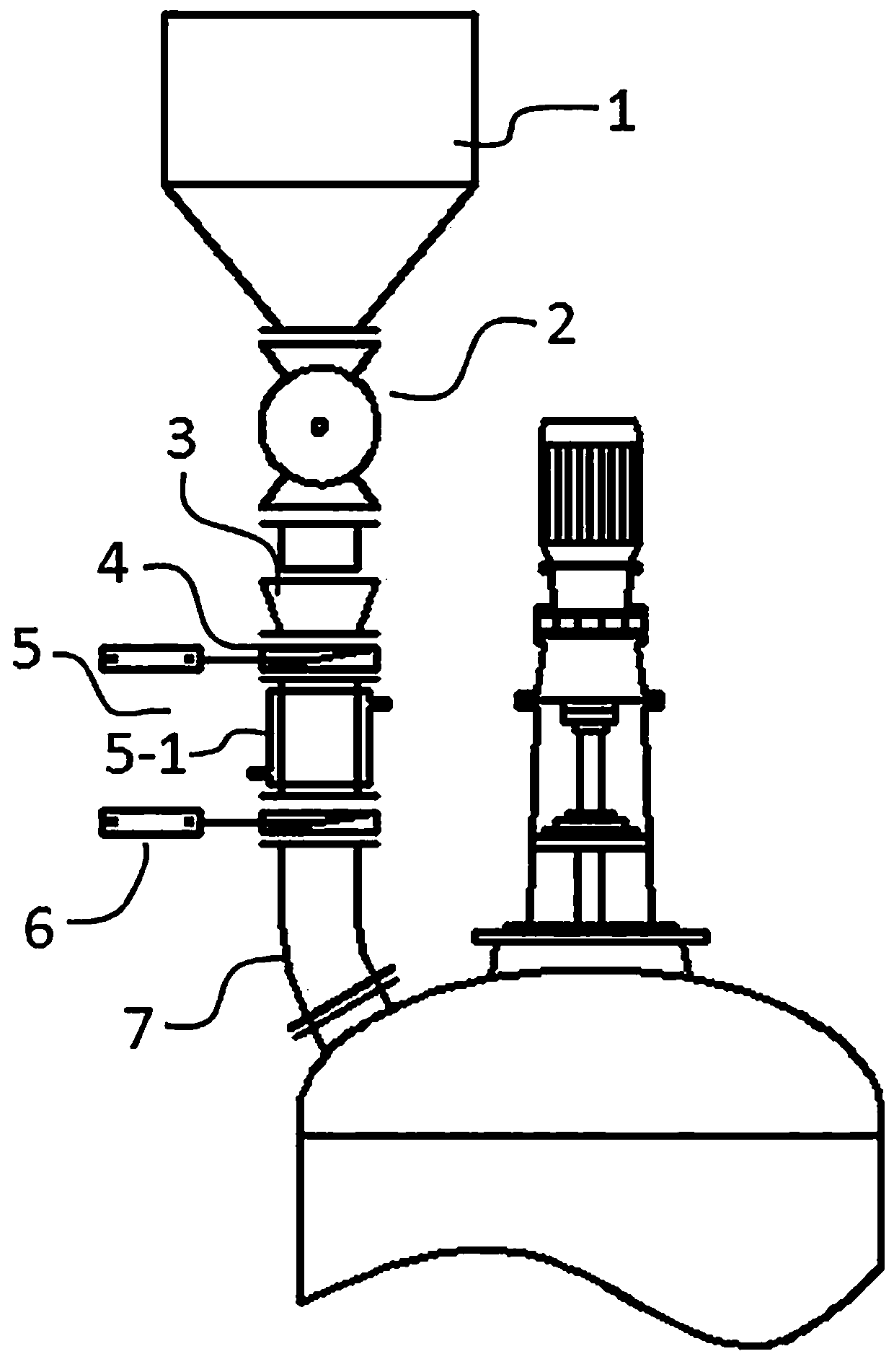

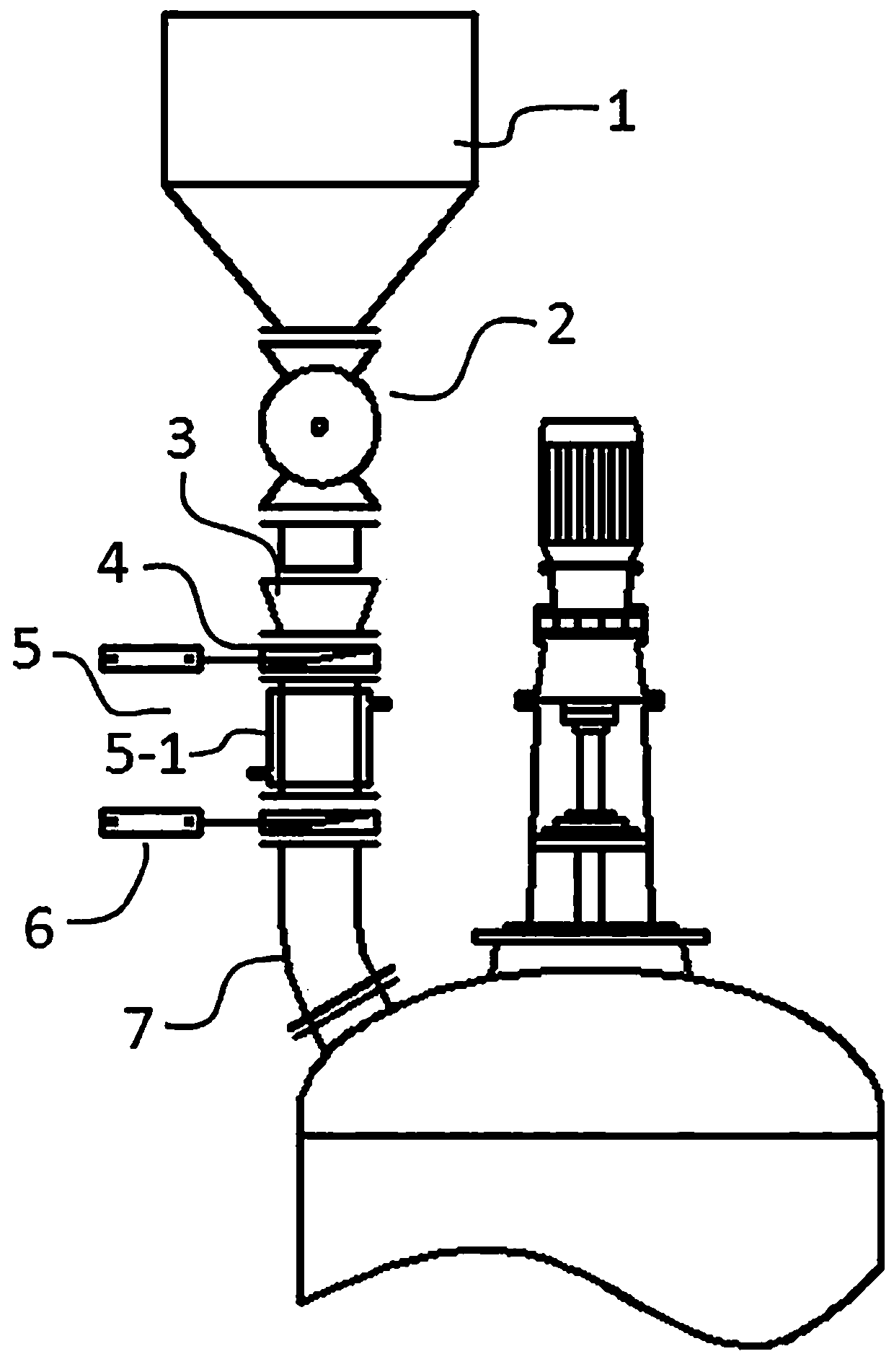

[0037] Example: Reference figure 1 , the feeding structure of the vertical copper phthalocyanine synthesis reaction kettle, which consists of a storage bin 1, a feeding device 2 that uses a discharge fan to close the fan, a feeding hopper 3, a first valve 4, a cooling bin 5, a second valve 6 and the reaction The feeding pipe 7 connected with the kettle constitutes.

[0038] Wherein, a cooling device 5-1 made of a water-cooling jacket is arranged outside the cooling bin 5 .

[0039] When actually feeding, the operator puts the material into the storage bin 1 on the kettle at one time, and then controls the speed of the unloading fan to control the feeding speed, and adds the material into the feeding hopper 3, and the valve on the first valve 4 When the flapper valve is opened, the material enters the cooling bin 5, and the cooling device 5-1 composed of the water-cooled jacket keeps the material solid without being melted, and then closes the flapper valve on the first valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com