A CNC machine tool for processing and deburring inner shaft parts

A CNC machine tool and parts processing technology, which is applied in the direction of metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve the problems of large wear at the transfer position of the turntable and affect the rotation of the turntable, so as to reduce the accumulation of pollutants and increase heat dissipation Sexuality and the effect of promoting air circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

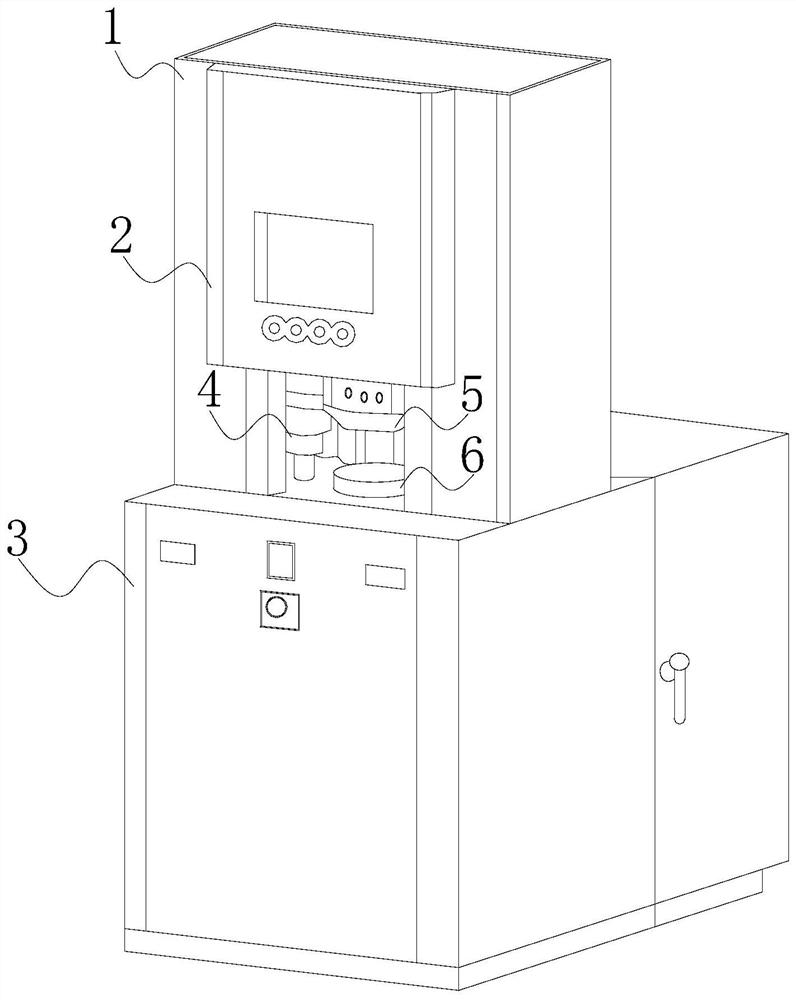

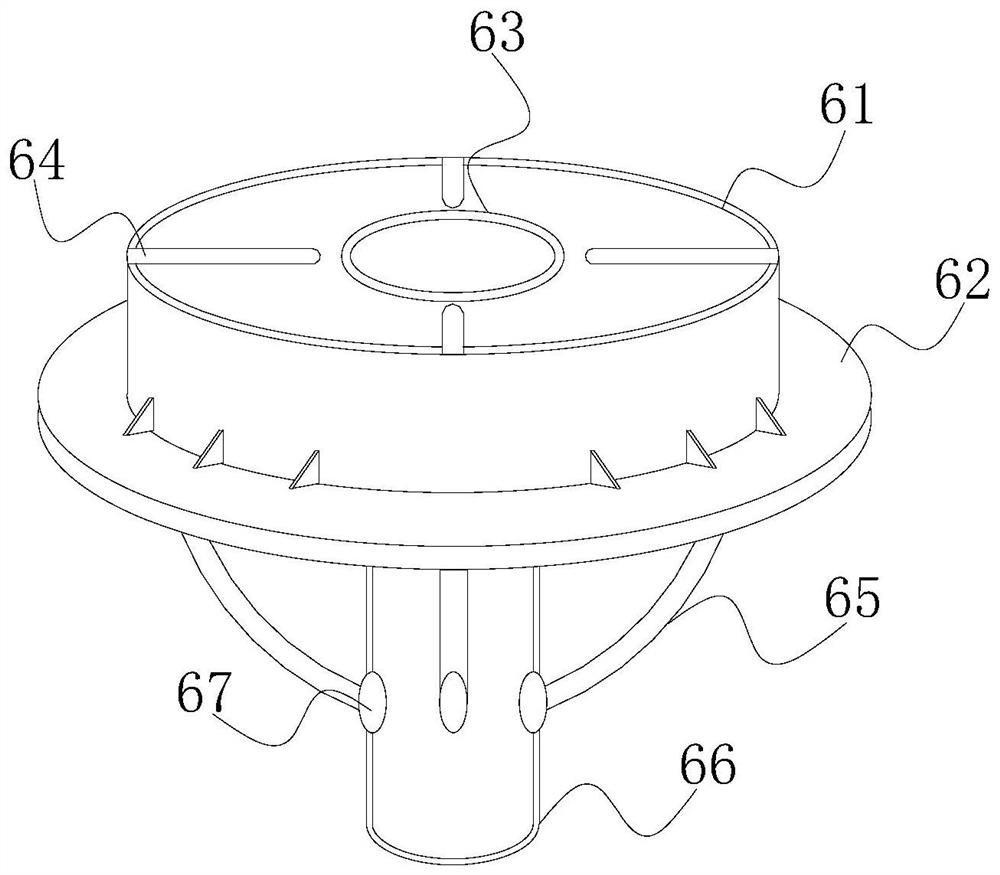

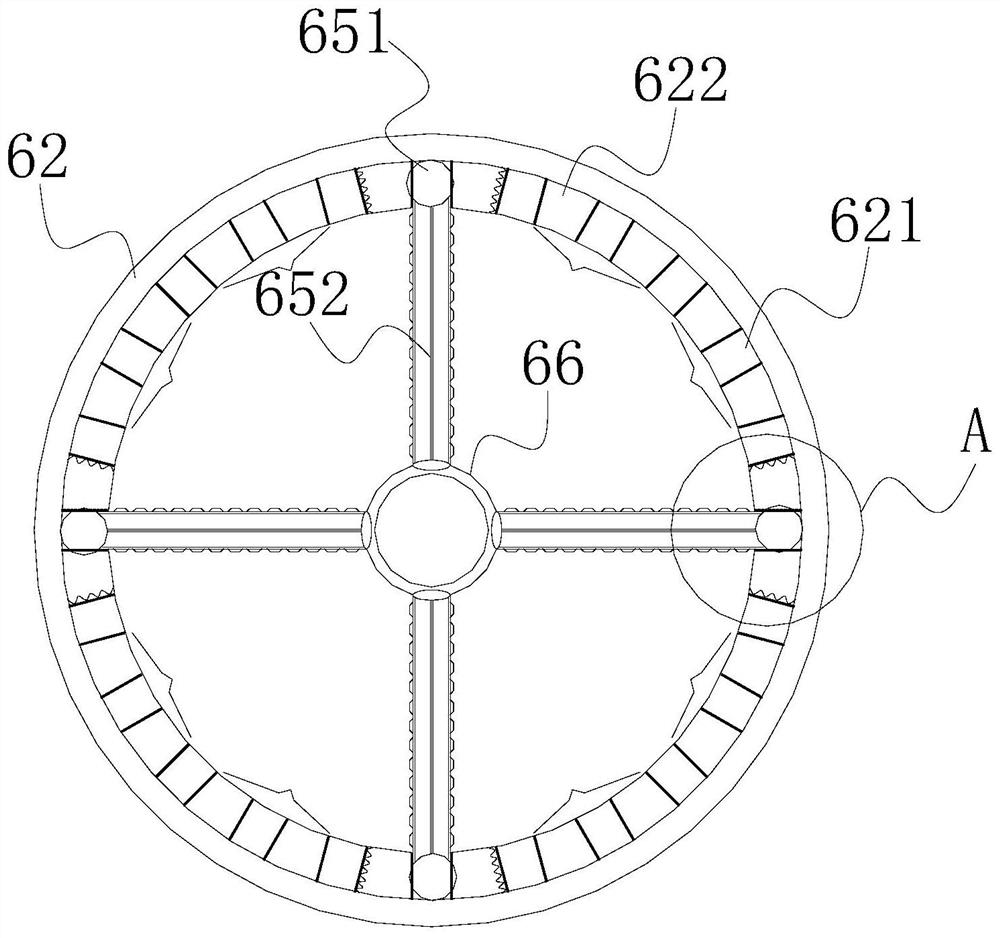

[0032] Such as Figure 1-Figure 5 As shown, the present invention provides a kind of in-axis part processing and deburring numerical control machine tool, its structure comprises workbench 1, electrical box 2, main frame 3, guider 4, reamer 5, turntable 6, and described workbench 1 is installed on On the main box 3, the electrical box 2 is arranged on the workbench 1, the electrical box 2 is electrically connected to the main box 3, and the guide 4, the reamer 5 and the turntable 6 are all fixed on the workbench 1 , the turntable 6 is provided with an object stage 61, a support plate 62, a fixed opening 63, an anti-slip strip 64, a leg mechanism 65, a rotating shaft 66, and a foot interface 67, and the object stage 61 is provided with an anti-slip strip 64 and a fixed port 63 , the fixed port 63 runs through the stage 61 and is connected with the rotating shaft 66. The rotating shaft 66 is divided into an inner shaft and an outer shaft, wherein the inner shaft is nested in the...

Embodiment 2

[0034] Such as Figure 1-Figure 5As shown, based on embodiment 1, the leg mechanism 65 realizes the function of preventing flash and burrs from falling in the rotating shaft without affecting the normal operation of the turntable, and the adsorption between the magnet and the magnetic disk realizes the connection between the limit empty rod and the support disk. It will deviate; under the traction of the traction strip, it is better to separate the magnet and the disk, which is convenient for the disassembly of the foot mechanism and better clean the inside of the shaft; the limit empty rod can be used to correct the traction of the traction strip and will not pull the deviation, so as to ensure that the disk and the On the basis of the effective disconnection of the magnet, the receiving structure 622 includes a solid groove 220, a connecting seat 221, a connecting rod 222, and a cam 223. One end of the connecting rod 222 is mechanically connected to rotate with a cam 223. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com