Three-dimensional board compounding method

A three-dimensional board and three-dimensional technology, which is applied in the field of three-dimensional board composite, can solve the problems of waste, increased energy consumption of drying composite three-dimensional boards, etc., and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

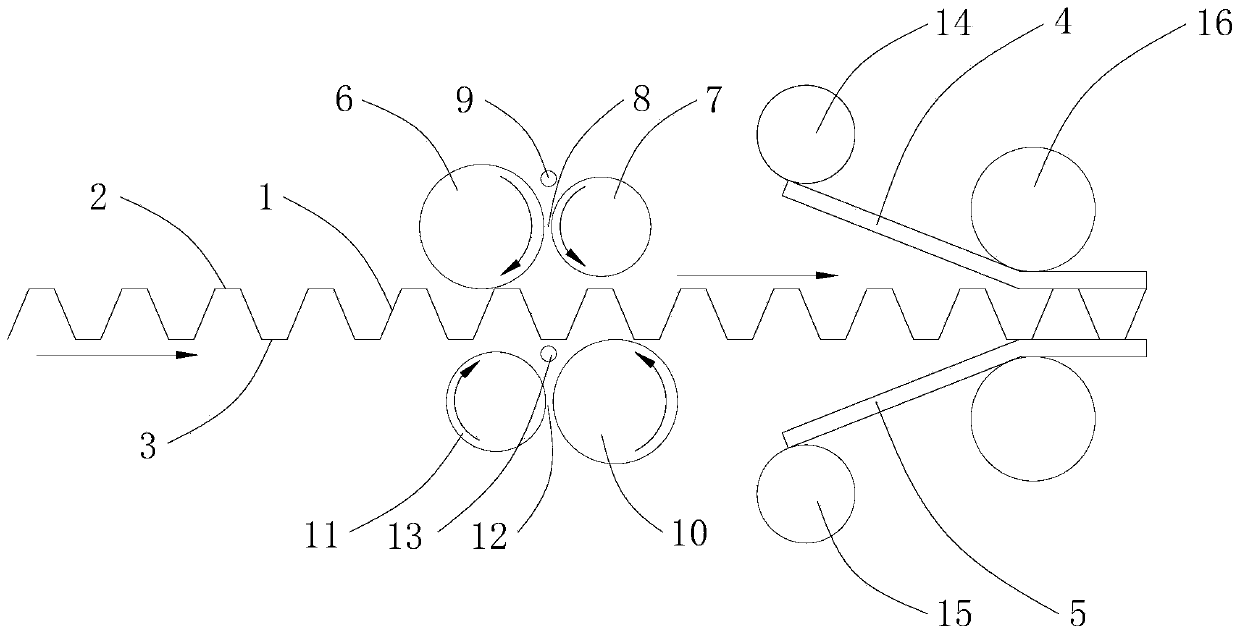

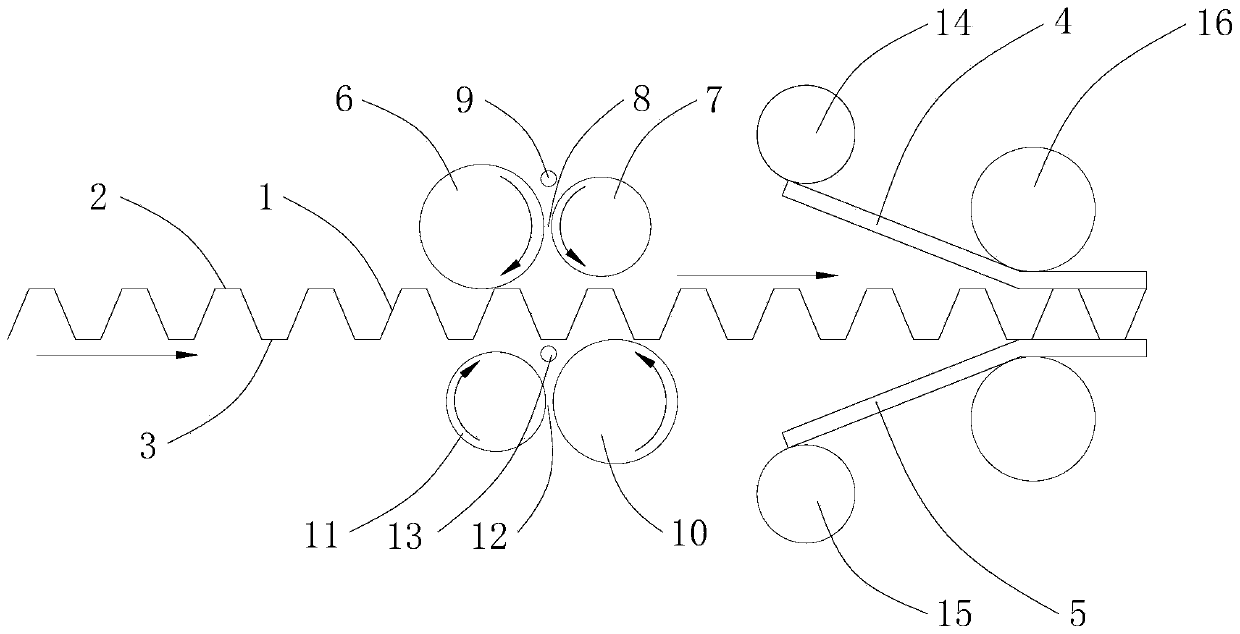

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] see figure 1 Shown, above-mentioned a kind of three-dimensional plate composite method comprises the following steps:

[0022] (1) Convey the three-dimensional core board 1 embossed by the flower roller along the feeding direction. The three-dimensional core board 1 is generally made of metal materials such as aluminum, copper, and iron; after being embossed by the upper and lower two flower rollers, a An upper convex pattern 2, and a lower convex pattern 3 is formed on the lower surface;

[0023] (2) The first gluing roller 6 and the first adjusting roller 7 which are parallel to each other and have the first gap 8 are arranged above the three-dimensional core plate 1, and the first gluing device 9 located above the first gap 8, the first coating The axial direction of the rubber roller 6 is perpendicular to the feeding direction, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com