Bottom cover separating device and packaging equipment

A material distribution device and bottom cover technology, applied in the directions of packaging, transportation and packaging, conveyor objects, etc., can solve the problems of slow speed of packaging machinery, slow material distribution speed, and unstable bottom cover material distribution. Achieve excellent mechanical properties and conductivity, avoid material jams and shortages, and avoid appearance defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

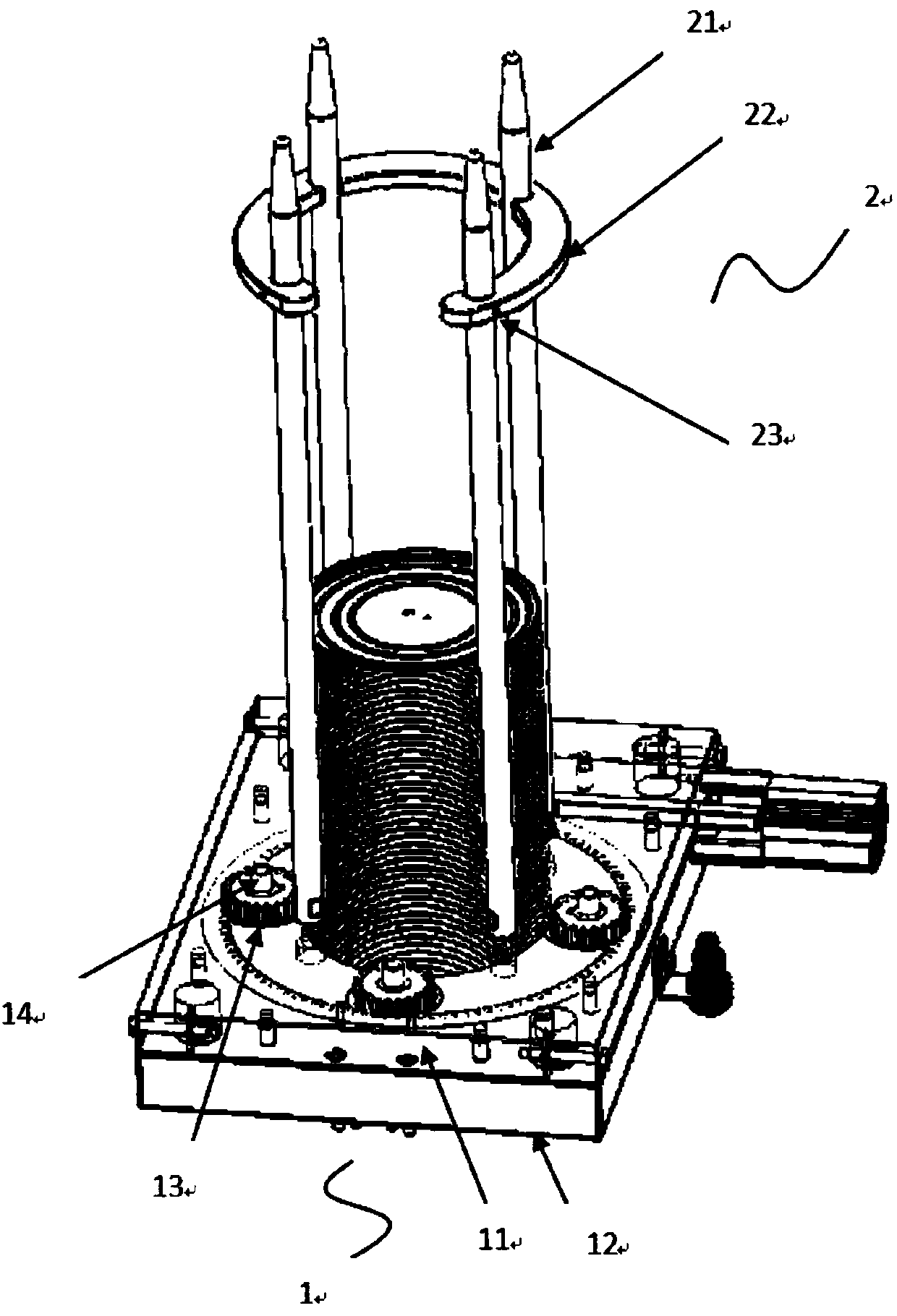

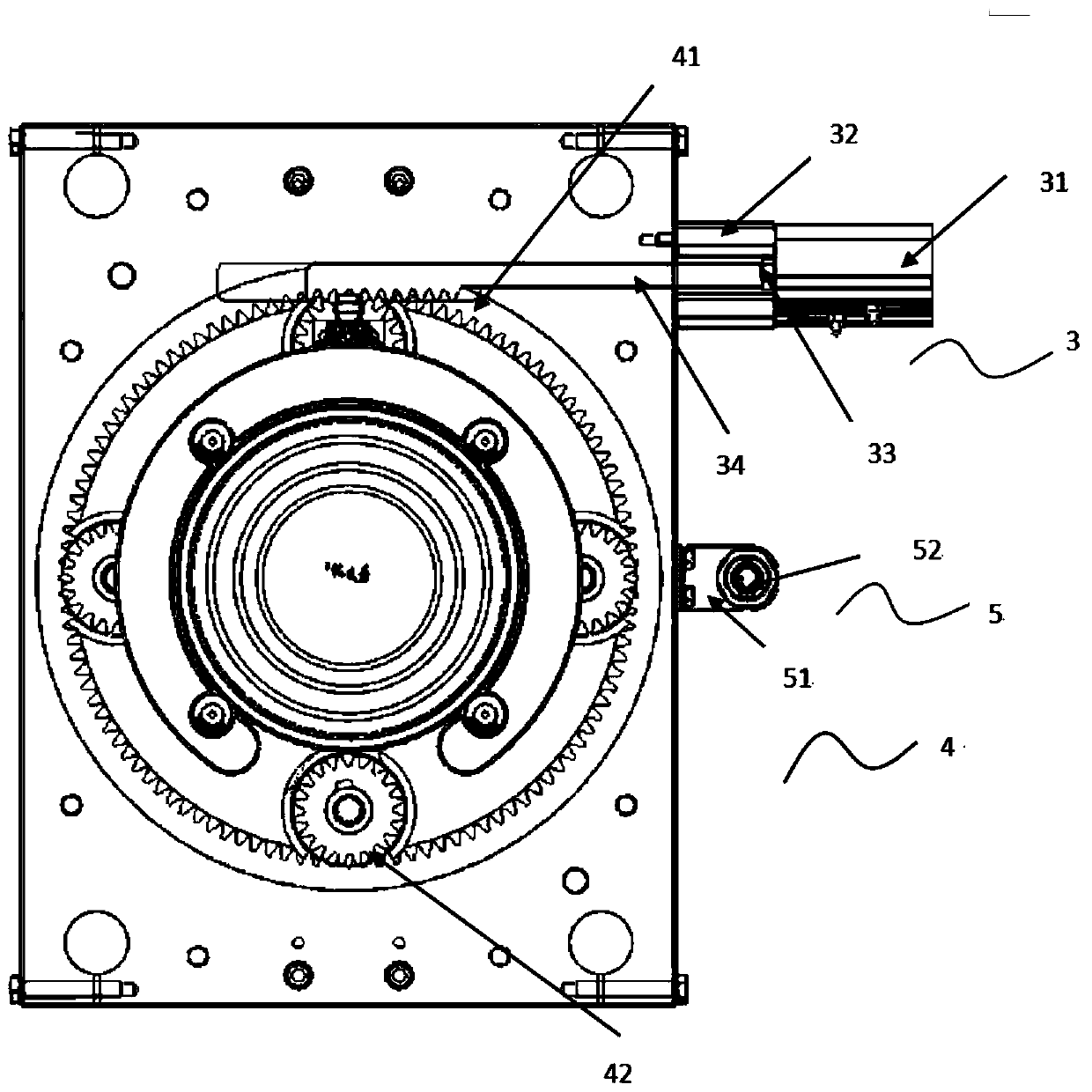

[0031] This embodiment one provides a material distributing device for the bottom cover, combined with figure 1 and figure 2 As shown, it includes: a blanking mechanism 1, a guiding mechanism 2, a driving mechanism 3 and a transmission mechanism 4;

[0032] The blanking mechanism 1 includes an upper cover plate 11, a lower cover plate 12, a cam 13 and a guide 14, the upper cover plate 11 is fixed on the lower cover plate 12 to form a cavity structure, and the cam 13 is fixed on the lower cover plate 12. In the cavity structure, the guide piece 14 is connected with the cam 13, the guide piece 14 is used to limit the rotation direction of the cam 13, and the cam 13 is used to divide the bottom cover one by one. ;

[0033] The guide mechanism 2 is arranged on the upper cover plate 11, and the guide mechanism 2 is used to transfer the bottom cover to the unloading mechanism 1;

[0034] The drive mechanism 3 is provided on one side of the cavity structure of the blanking mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com