Punching device for soil nailing wall

A technology of soil nailing walls and workbenches, which is applied to earth movers/excavators, construction, etc., can solve the problems that the angle cannot be adjusted arbitrarily, and the inclination angle error of soil nail holes is large, so as to improve the construction quality and efficiency, The effect of reducing hole forming error and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

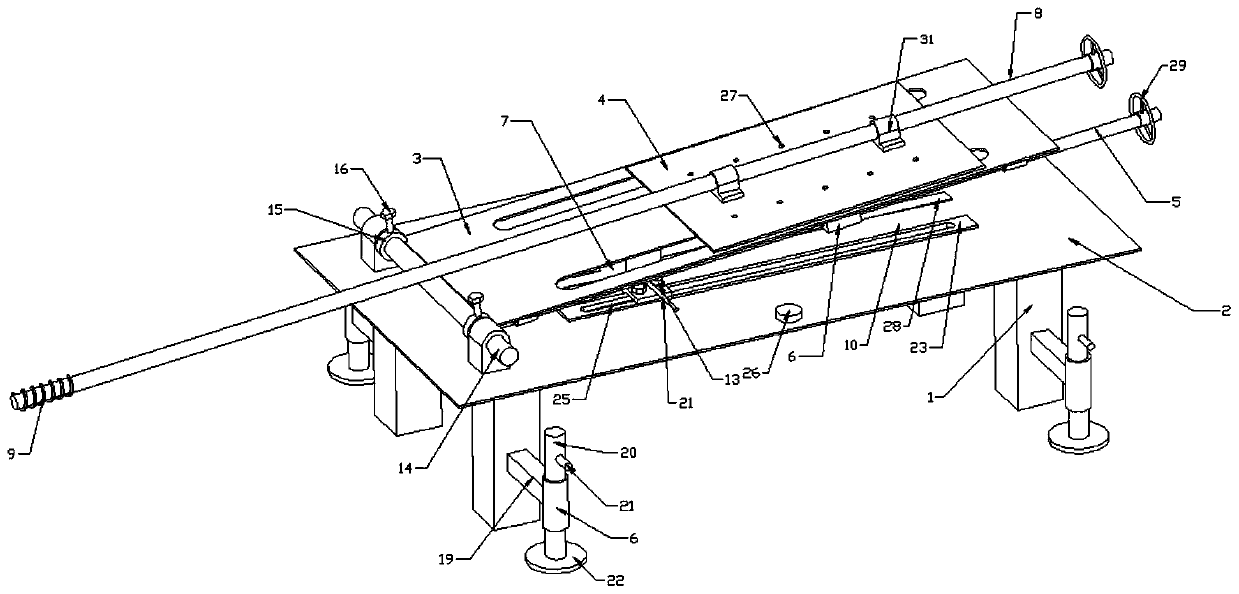

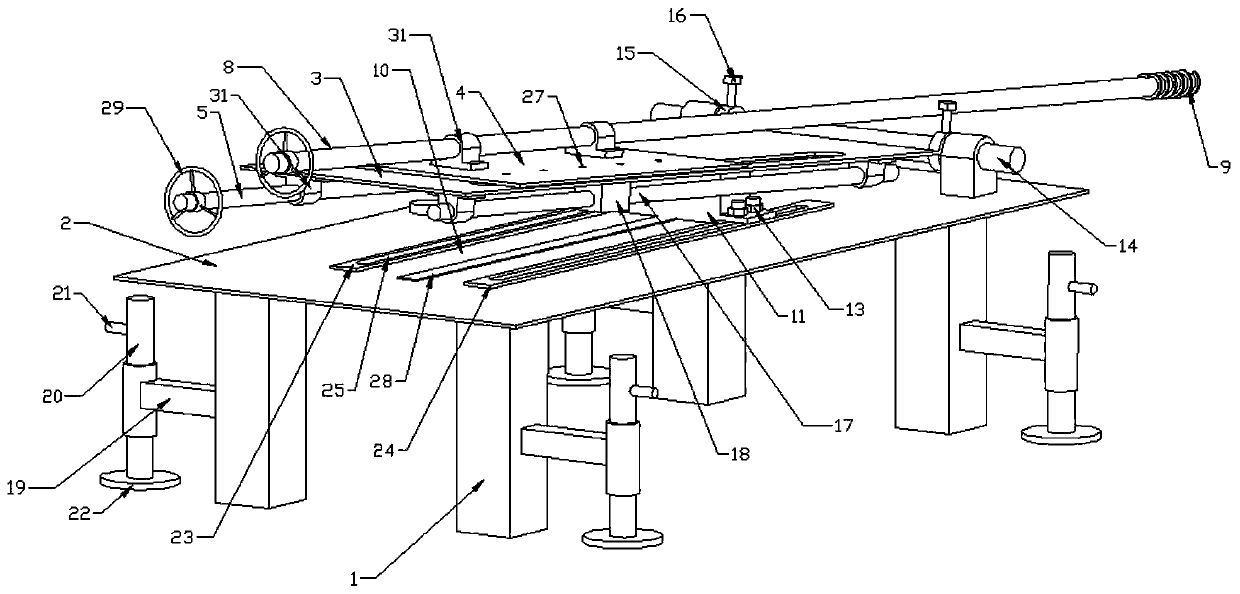

[0039] This embodiment, as the basic embodiment of the present invention, discloses a device for opening holes in soil nail walls. The specific structure is as follows: figure 1 As shown, it includes a frame 1, the top of the frame 1 is fixedly provided with a workbench 2, and one end of the workbench 2 is fixedly provided with an articulated shaft 14, and two sets of connecting supports are rotatably connected on the articulated shaft 14 through a rotating pair. Ears 15, the two connecting lugs 15 are fixedly connected with the console 3 at the same time, so as to realize the hinged connection between the workbench 2 and the console 3, and at the same time, the connecting lugs 15 are also threaded with locking bolts 16, The fixing of the console is realized by pressing the end face of the locking bolt 16 against the end face of the hinge shaft 14;

[0040] The first baffle plate 23 and the second baffle plate 24 parallel to each other are fixedly arranged on the workbench 2, ...

Embodiment approach 2

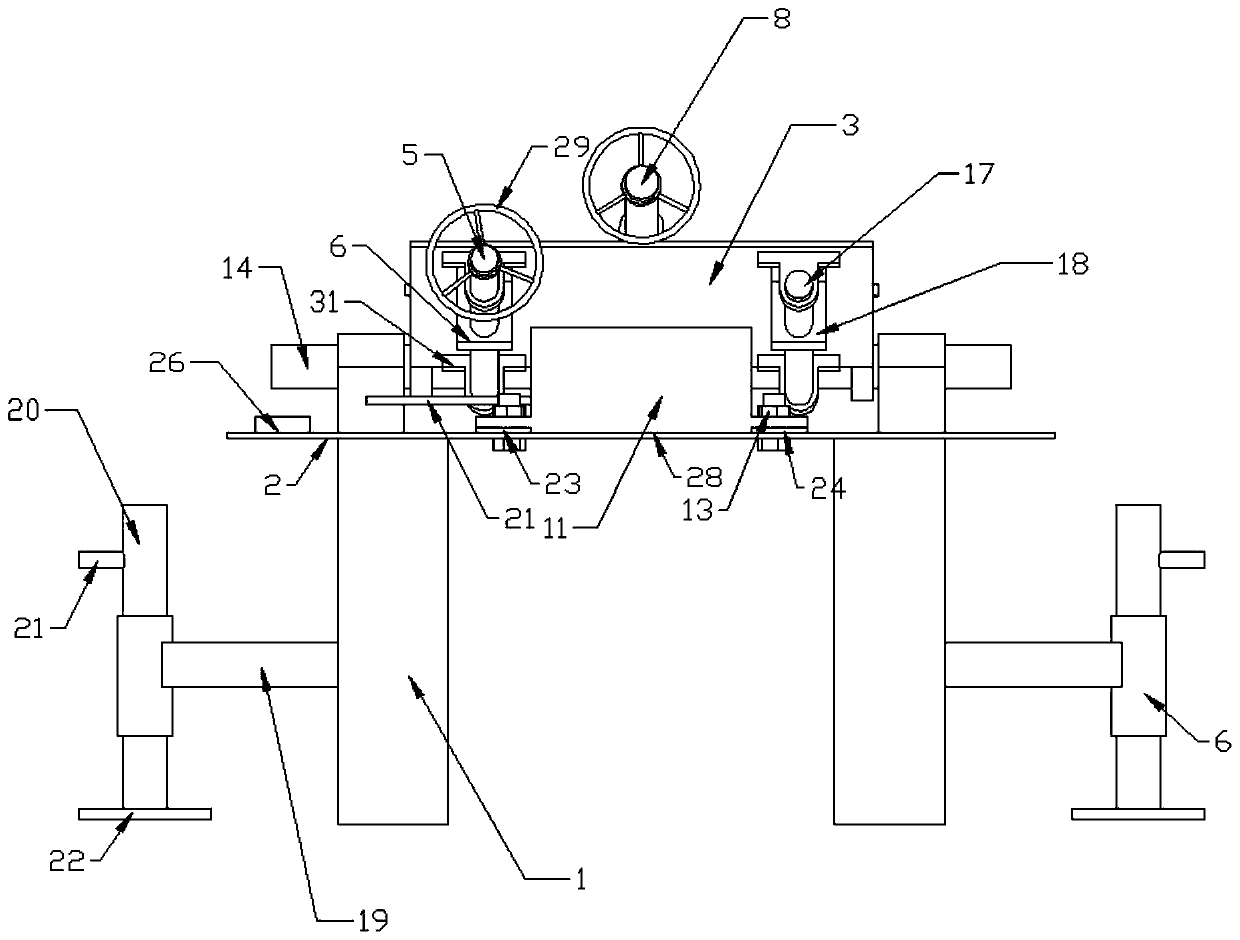

[0043] This embodiment, as a preferred embodiment of the present invention, discloses a soil nailing wall opening device, including a frame, the specific structure is as follows: Figure 1 to Figure 7 As shown, it includes a frame 1, the frame 1 is provided with a workbench 2, the workbench 2 is hinged with an operation table 3, and the operation table 3 is slidably provided with a movable workbench 4, and the operation table 3 The bottom surface is fixedly provided with a sliding rod 17 through the connecting seat, and a chute 7 is also provided on the operating table 3. The bottom surface of the movable workbench 4 is fixedly provided with a linear bearing seat 18, and the linear bearing seat 18 passes through the chute 7 and the sliding rod. 17 interactive connection;

[0044] Further, on the four supporting legs of the frame 1, a connecting rod 19 is fixedly arranged, and a connecting sleeve 6 is welded on the connecting rod 19, and a telescopic support rod 20 is connected...

Embodiment approach 3

[0047] This embodiment is another preferred embodiment of the present invention, which discloses a soil nailing wall opening device, the specific structure is as follows Figure 8 As shown, a workbench 2 is included, an operation platform 3 is hinged on the workbench 2, and a scissor lifting frame 30 is fixedly connected to the bottom surface of the workbench 2 at the same time.

[0048] When the present invention is in use, first place the whole set of equipment at the working point, and carry out leveling through horizontal air bubbles, then change the inclination angle of the console to a specified angle by changing the position of the adjustment block, and then adjust the rotating shaft after the console is fixed. The rotating wheel drives the drill bit to rotate, while the drill bit rotates, the movable worktable is continuously pushed forward by rotating the adjusting screw, and then the drill bit is continuously pushed into the hole;

[0049] Compared with the prior art...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com