Service life test equipment and method capable of realizing multidirectional stress of motor

A life test, multi-directional technology, used in motor generator testing and other directions, can solve problems such as project failure, affecting the progress of new product development, and inaccurate test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

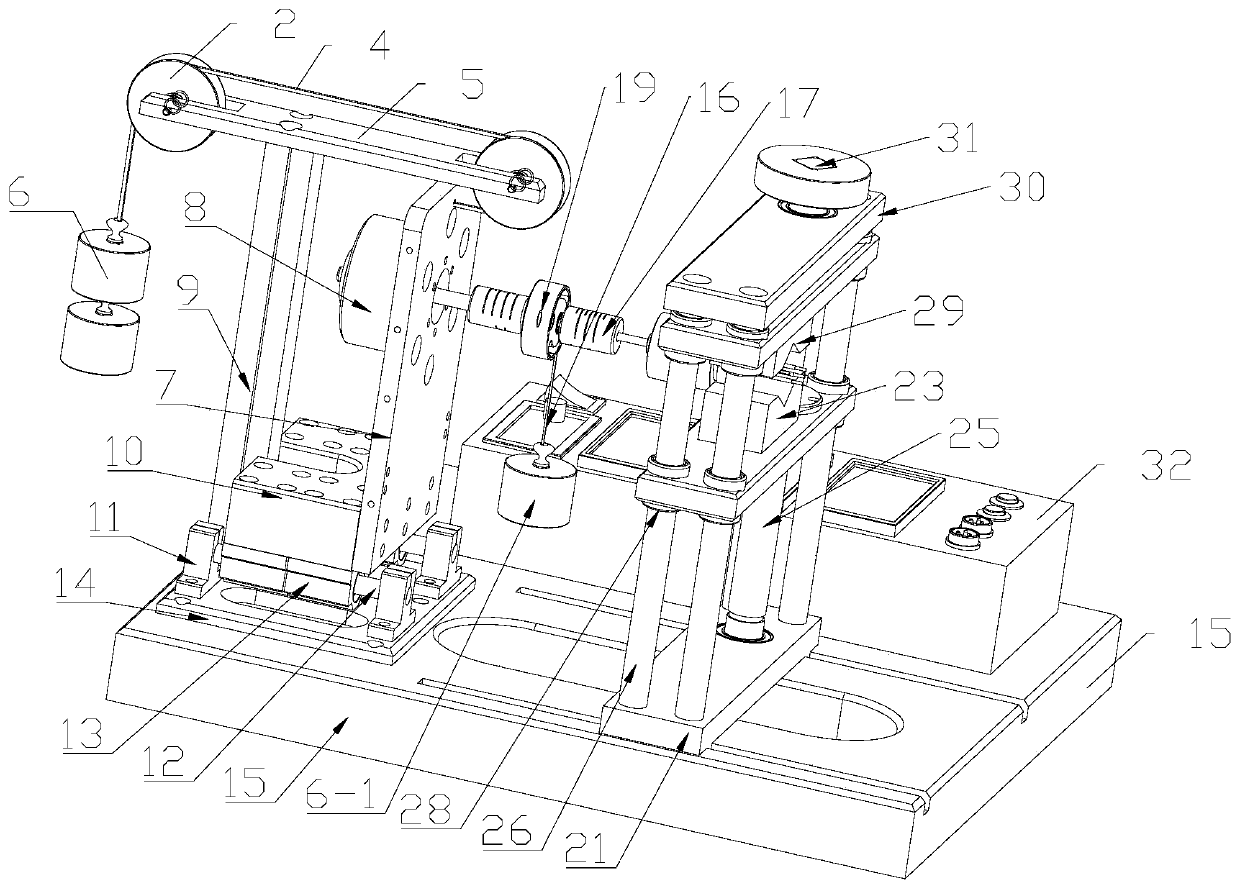

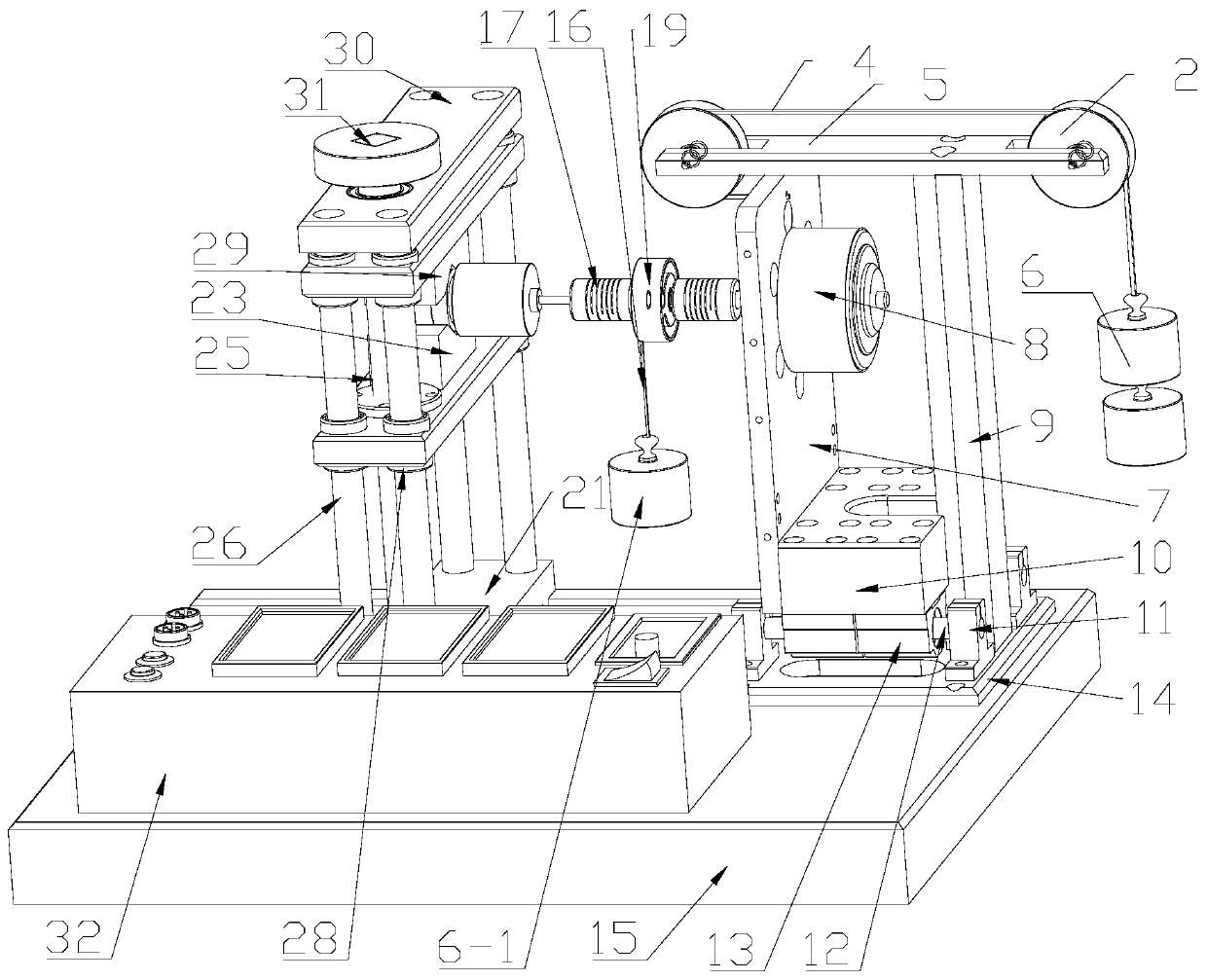

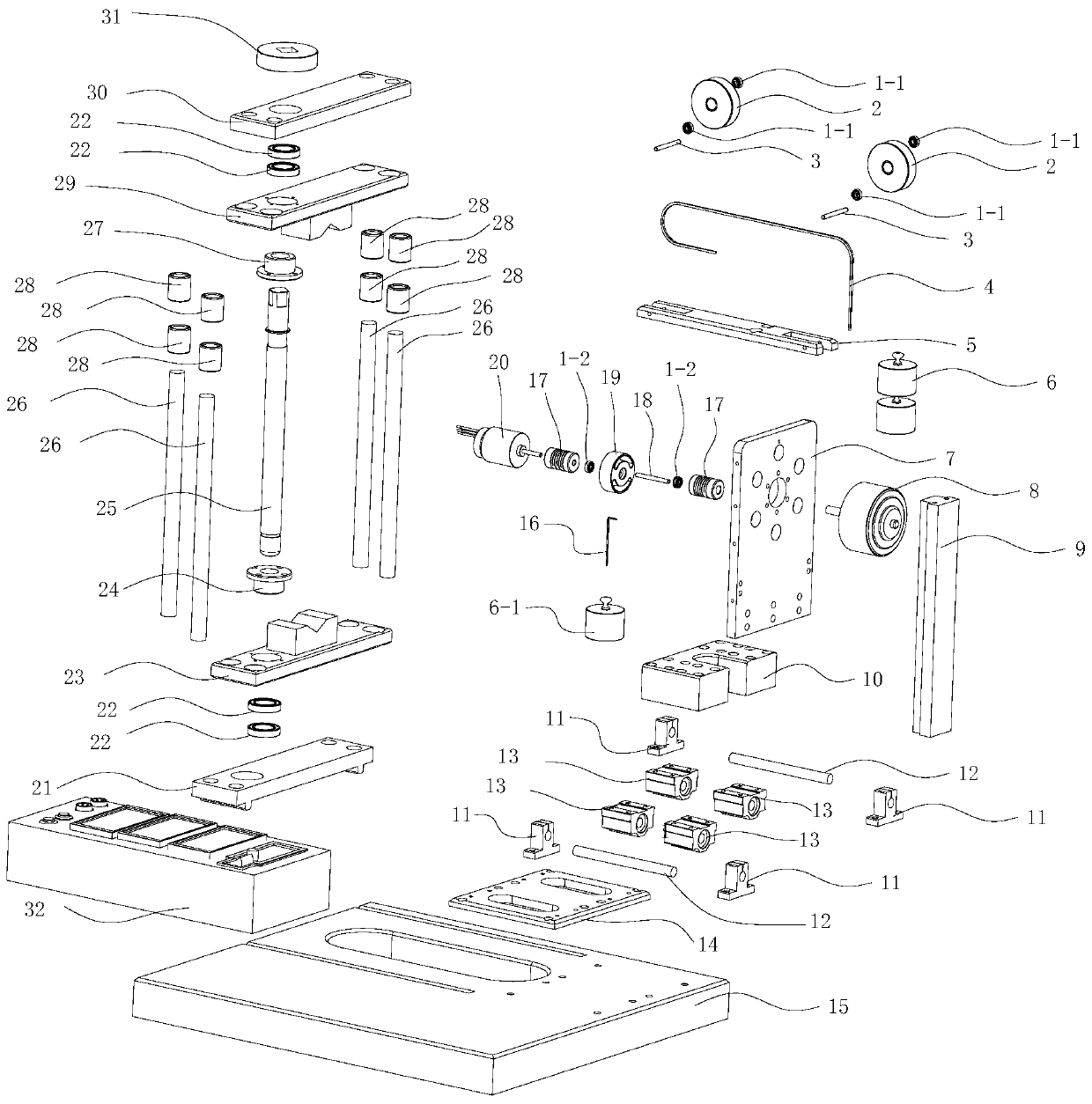

[0025] This embodiment is a life test device that can realize the multi-directional force of the motor, such as Figure 1-3 As shown, it includes a slide-type force-receiving device, a motor clamping device, a control box 32 and a motor to be tested 20. The motor to be tested is located between the slide-type force-receiving device and the motor clamping device, and the motor clamping device includes a vertically opposite The V-shaped movable upper plate 29 and the V-shaped movable lower plate 23 are provided. The V-shaped movable upper plate and the V-shaped movable lower plate move in the vertical direction in opposite directions. The sliding table force-bearing device includes a sliding table assembly, a pulley assembly and a motor shaft. The connecting assembly uses gravity to apply horizontal axial force and radial force to the shaft of the motor to be tested. The sliding table assembly is provided with a hysteresis brake 8 to apply rotational torque. The control box contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com