A resin flow control method for rfi integral molding of hat-shaped reinforced wall panels

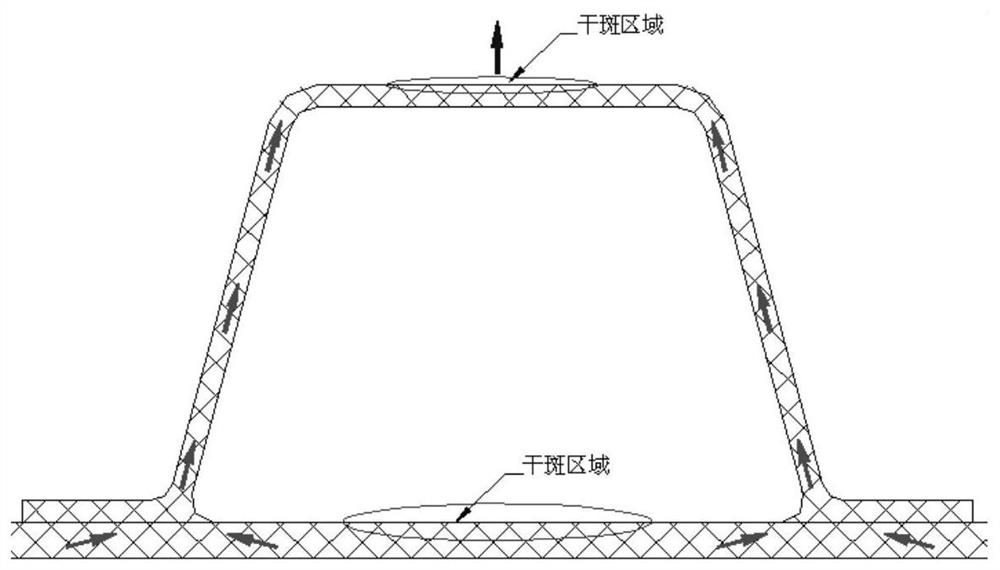

A technology of resin flow and reinforced siding is applied in the field of resin flow control of RFI integral molding of hat-shaped reinforced siding, which can solve the problems of easy occurrence of dry spots and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: A test piece of a hat-shaped reinforced wall panel with a size of 1.5m×0.7m, with two hat-shaped reinforcements 9 equal in length to the skin 10, and the bottom flange of the hat-shaped reinforcement is sewn to the skin 10 Then it is shaped by RFI process. The hat-shaped composite material reinforced wall plate test piece was prepared by using this scheme, and the specific operation method is as follows:

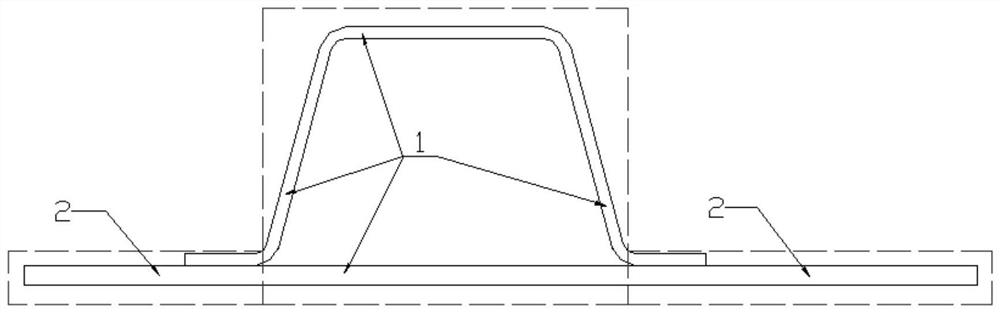

[0048] a. Structural unit division of hat-shaped reinforced panel

[0049] In order to realize the resin flow control of the hat-stiffened panel, the structure of the hat-stiffened panel was decomposed. The two side walls of the hat-shaped reinforcement, the top of the hat, and the skin at the bottom of the hat-shaped reinforced cavity are regarded as a ring structure 1, and the lower flange of the hat-shaped reinforcement and the skin outside the hat-shaped reinforced cavity form a plate shape Structure 2.

[0050] b. Select a resin flow model suitable ...

Embodiment 2

[0058] Embodiment 2: A hat-shaped reinforced wall panel with a size of 6.0m×0.9m, with 4 hat-shaped reinforcements 9 and a length of 4.5m. Stitched with skin and shaped by RFI process. The hat-shaped composite material reinforced wallboard is prepared by using this scheme, and the specific operation method is as follows:

[0059] a. Structural unit division of hat-shaped reinforced panel

[0060] In order to realize the resin flow control of the hat-stiffened panel, the structure of the hat-stiffened panel was decomposed. The skin on both sides of the hat-shaped reinforcement, the top of the hat, and the bottom of the hat-shaped reinforced cavity is regarded as a ring structure 1, and the bottom flange of the hat-shaped reinforcement and the skin outside the hat-shaped reinforced cavity form a plate-shaped structure 2.

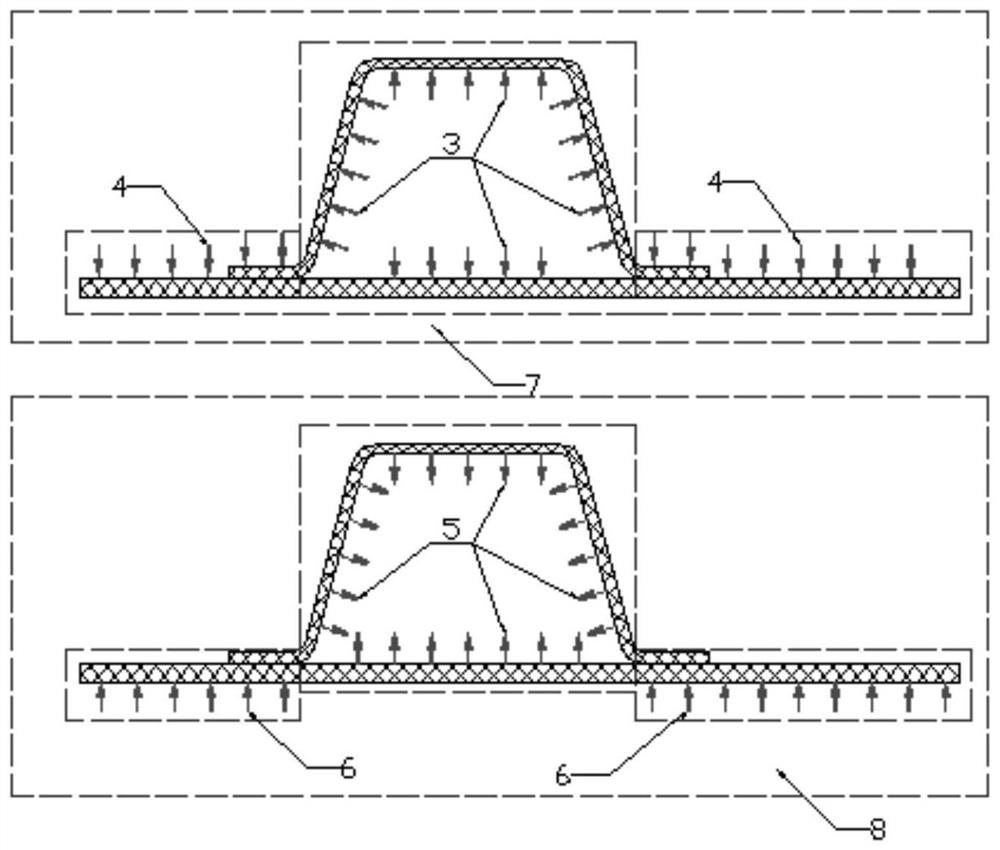

[0061] b. Select a resin flow model suitable for RFI molding of hat-shaped reinforced wall panels

[0062] The first resin flow control model 7 of the hat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com