A method for stitching/resin membrane infiltration molding resin matrix composites

A composite material and resin film technology, applied in the field of composite material manufacturing, can solve the problems of complex resin flow channel design, inconsistent permeability of preforms, and different permeability rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

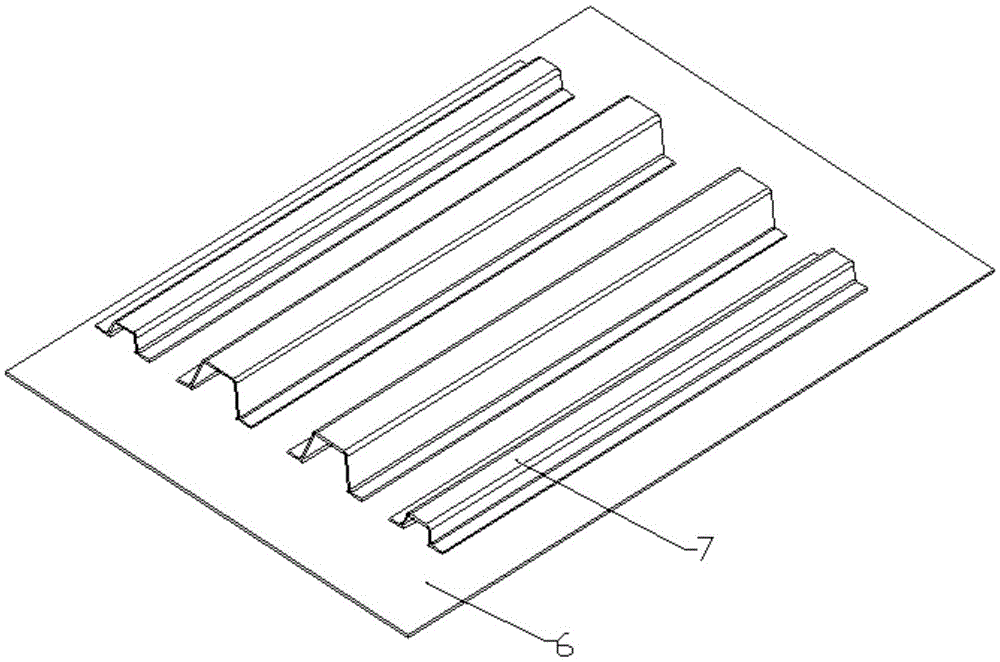

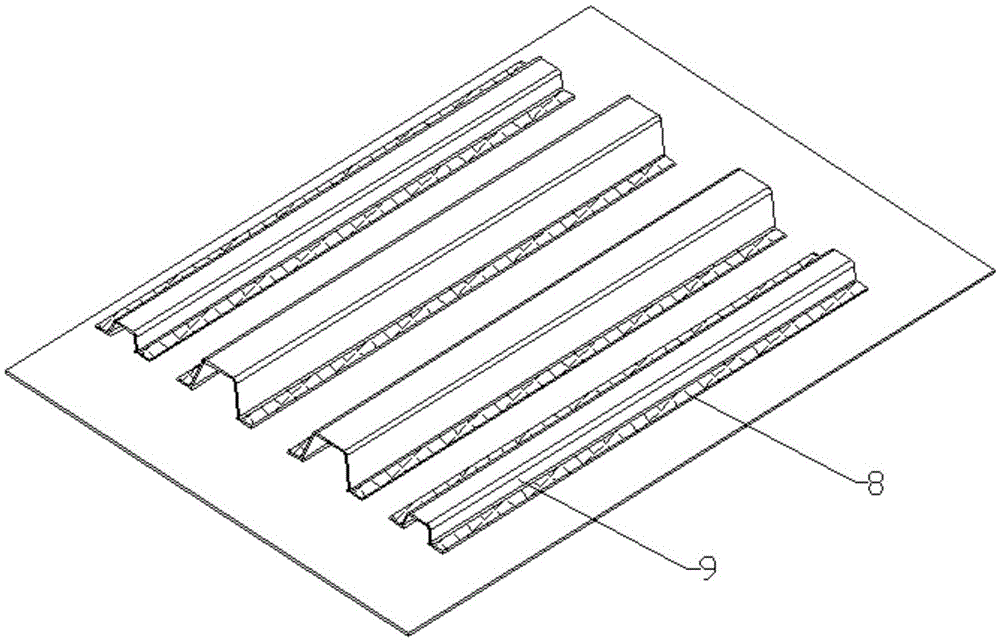

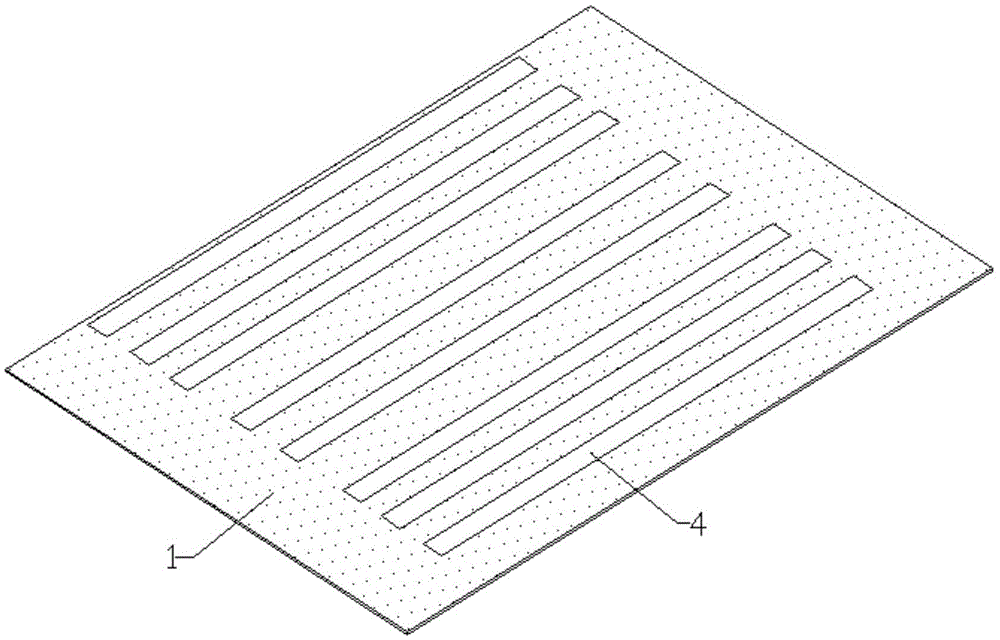

[0165] Example 1: figure 1 The typical hat-shaped stiffened wall panel shown, the outer dimension of the wall panel is 1500mm×800mm, the skin 6 has 4 hat-shaped stiffeners 7, the material is U7192 / QY9512, the skin is 24 layers, and the reinforcement is 16 layers. The fiber volume content is required to be 60%. U7192 carbon fiber fabric surface density is 195g / m 2 , U7192 carbon fiber fabric uses T700 fiber density 1.81g / cm 3 , QY9512 resin density 1.24g / cm 3 . Use stitching technology to connect the flange of the hat-shaped reinforcement 7 with the skin 6 figure 2 The part stitching area 8 is stitched and integrally formed by the RFI process. The process steps are as follows:

[0166] a. Analyze the composition of typical parts, which are divided into skin 6-layer unit and reinforced 7-layer unit. The skin 6 ply unit and the reinforced 7 ply unit are partitioned according to the stitched and non-stitched areas respectively. The skin stitched area 4 is obtained by offsetting 5...

Embodiment 2

[0213] Example 2: Such as Figure 7 The structure of the hat-shaped stiffened wall panel is shown. The outer size of the wall panel is 4900mm×900mm, and the outer skin 6 is flat, with 4 hat-shaped stiffeners 7 with a total of 20 sections and two different cross-sectional sizes. The material is U7192 / QY9512, 20 layers of skin, 10 layers of reinforcement, and 56% fiber volume content is required. U7192 carbon fiber fabric surface density is 195g / m 2 , U7192 carbon fiber fabric uses T700 fiber density 1.81g / cm 3 , Toughened QY9512 resin density 1.24g / cm 3 . In order to improve the structural integrity, stitching technology is used to connect the cap-shaped ribbed flange with the skin. Figure 8 The stitching area 8 shown is stitched, and the remaining areas require interlayer toughness and require the use of RFI technology for integral molding. The process steps are as follows:

[0214] a. Wall panels are divided into skin 6-ply units and stiffened 7-ply units according to skin and...

Embodiment 3

[0261] Example 3: Such as Picture 12 The structure of "J" stiffened siding is shown, and the skin 14 has 5 "J"-shaped stiffeners 15. The material is U3160 / QY9512, the skin is of variable thickness, 22 layers are fully laid, the thickened area 16 has 6 layers of intercalation, and the reinforcement is a total of 16 layers of equal thickness, and the fiber volume content is 58%. U3160 carbon fiber fabric surface density is 160g / m 2 , U3160 carbon fiber fabric uses T300 fiber density 1.76g / cm 3 , Toughened QY9512 resin density 1.24g / cm 3 . In order to improve the strength of the interface between the reinforcement and the skin, the stitching technology is used to stitch the lower flange stitching area 8 and the skin 14 on both sides of the "J"-shaped reinforcement. The remaining areas require interlayer toughening and the RFI process is required. Perform integral molding. We adopted the technical solution of the present invention, and the specific process steps are as follows:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com