A method for resin film infiltration molding resin-based composite materials

A composite material and resin film technology, applied in the field of composite material manufacturing, can solve the problems of difficult control of resin content uniformity, fiber bending, wrinkling, etc., and achieve an effect that is conducive to precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

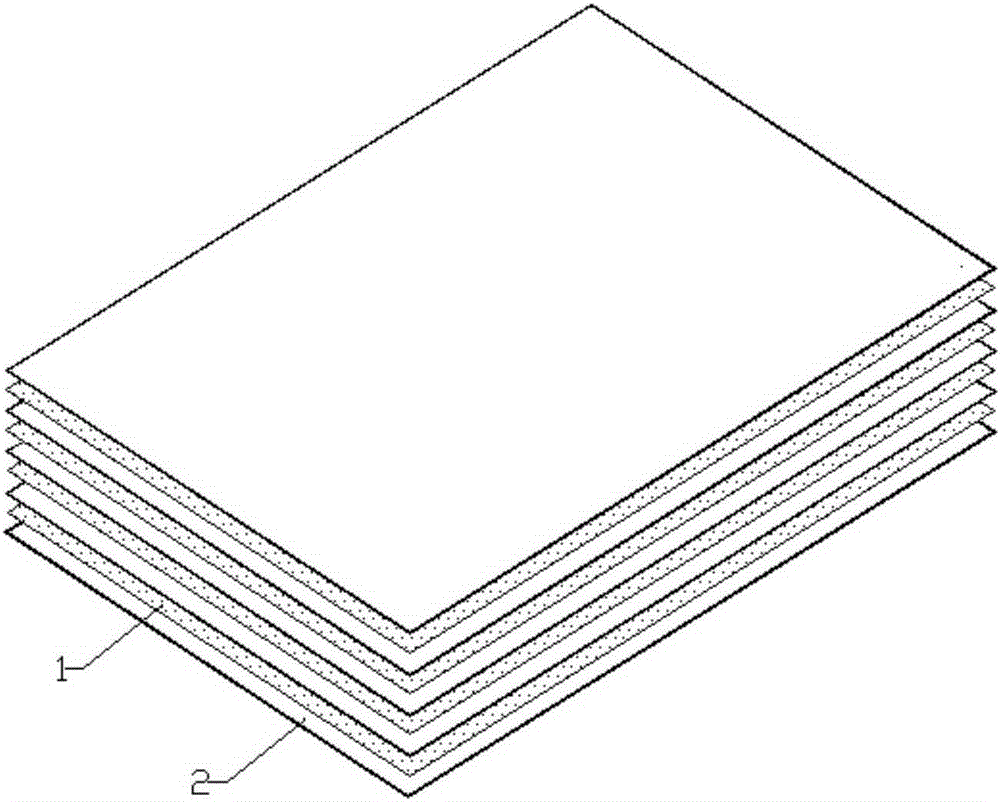

[0093] Example 1: A plate with a size of 850mm×670mm. The material of the plate is U7192 / QY9512, and there are 24 layers of U7192 carbon fiber fabrics. The fiber volume content of the formed plate is required to be 60%. The surface density of U7192 carbon fiber fabric is 195g / m 2 , U7192 carbon fiber fabric adopts T700 fiber density 1.81g / cm 3 , QY9512 resin density 1.24g / cm 3 . We adopt the RFI forming technology of the present invention, and the specific process steps are as follows:

[0094] a. Calculate the surface density of the resin film corresponding to the single-layer fabric according to the fiber volume content of the part, the surface density of the fabric used, the fiber density used in the fabric, and the matrix resin density, accurate to one decimal place.

[0095] W R 0 = ( 1 - V f ...

Embodiment 2

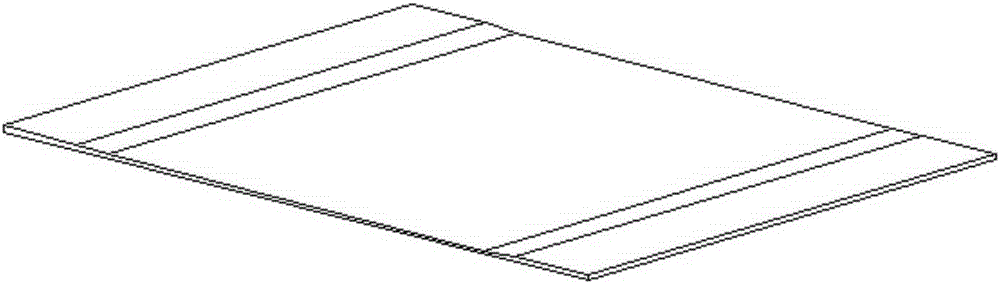

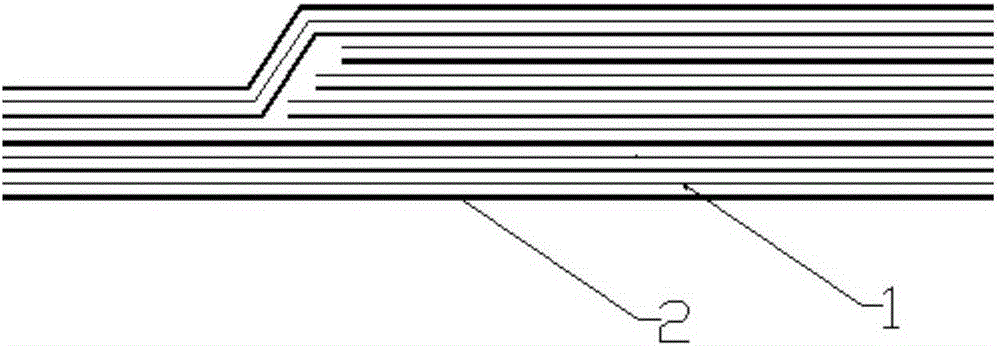

[0116] Example 2: figure 2 The outer dimension is 1000mm×650mm, which is a variable-thickness wall panel structure. The material is G0827 carbon fiber fabric. The number of fabric layers is 22 layers, both ends are thickened, and each end has 18 layers of intercalation. Inter-toughening, the wallboard fiber volume content is 58%, and the RFI forming technology of the present invention is adopted. G0827 carbon fiber fabric, areal density 160g / m 2 , G0827 fabric adopts T300 fiber density 1.76g / cm 3 , toughened QY9512 resin density 1.24g / cm 3 . The specific process steps are as follows:

[0117] a. Calculate the surface density of the resin film corresponding to the single-layer fabric according to the fiber volume content of the part, the surface density of the fabric used, the fiber density used in the fabric, and the matrix resin density, accurate to one decimal place.

[0118] W R 0 = ...

Embodiment 3

[0140] Embodiment 3: The structure of the outer wall plate of the box section test piece is as follows Figure 4 , the overall dimensions are 900mm×520mm×105mm (length×width×height), and there are 5 “J”-shaped reinforcements in the longitudinal direction. 30 layers, reinforced with 15 layers of G0827 carbon fiber fabric, the resin adopts QY9512 resin and requires interlayer toughening, and the fiber volume content of the outer wall plate requires 58%, which is integrally formed by RFI technology. The surface density of G0827 carbon fiber fabric is 160g / m 2 , G0827 carbon fiber fabric adopts T300 fiber density 1.76g / cm 3 , toughened QY9512 resin density 1.24g / cm 3 . Here we adopt the technical scheme of the present invention, and concrete processing steps are as follows:

[0141] a. Calculate the surface density of the resin film corresponding to the single-layer fabric according to the fiber volume content of the part, the surface density of the fabric used, the fiber dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com