Fingerprint developing powder as well as preparation method and application thereof

A fingerprint and magnetic powder technology, applied in applications, medical science, sensors, etc., can solve the problems of good display effect, high price, carcinogenicity, etc., and achieve the effect of simple preparation process, wide source, and not easy to raise dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

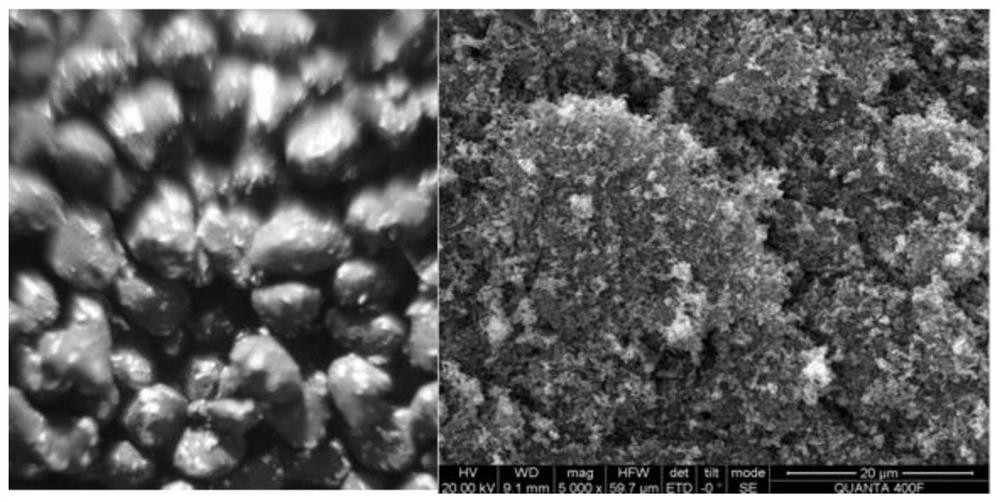

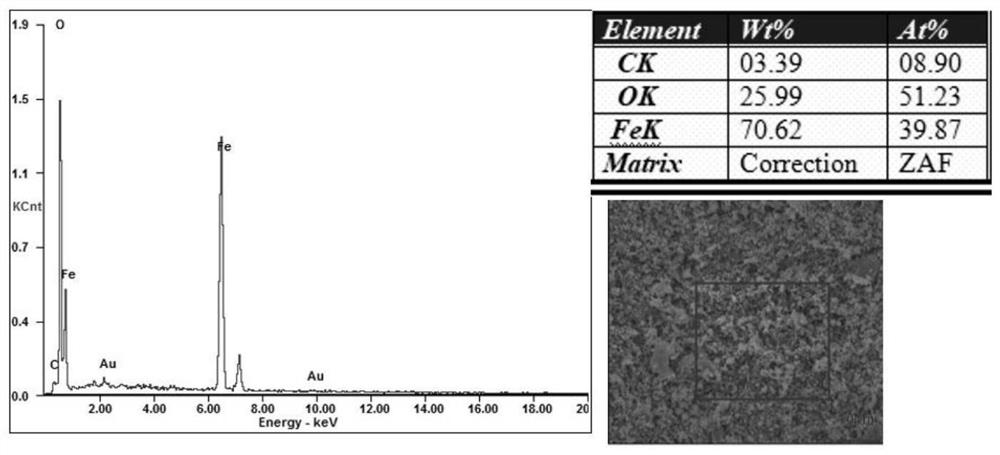

[0057] In this embodiment, a black fingerprint revealing powder is prepared, and the specific preparation process is as follows:

[0058] Weigh 4.5 grams of iron powder with an average particle size of 200 μm, 0.45 grams of 3.5 μm ferric oxide, and 0.01 gram of 5 μm graphite; weigh 0.18 grams of pentaerythritol, dissolve it with 15 ml of methanol at room temperature, and set aside; pour the iron powder into the stirring device , add a citric acid solution with a concentration of 2% to cover the surface of the magnetic powder, start stirring at 100-220rpm, stir for 10-15min, stop stirring and filter, rinse the filter cake with absolute ethanol or methanol for more than three times, take out the filter cake, and put it under nitrogen Drying in the atmosphere completes the iron powder modification. Pour the modified iron powder into the pentaerythritol solution, ultrasonicate for 10 minutes, and volatilize the solvent while stirring in the rotary steamer until the magnetic powder...

Embodiment 2

[0065] In this example, a black-gray fingerprint powder is prepared, and the specific preparation process is as follows:

[0066] Weigh 4.5 grams of nickel powder with an average particle size of 200 μm and 0.4 grams of graphite with a diameter of 5 μm; dissolve 0.18 grams of pentaerythritol with 15 milliliters of methanol at room temperature and set aside; pour the nickel powder into the stirring device, and add a 2% citric acid solution to cover On the surface of the magnetic powder, start stirring at 100-220rpm, stir for 10-15min, stop stirring and filter, rinse the filter cake with absolute ethanol or methanol for more than three times, take out the filter cake, and dry in a nitrogen atmosphere to complete the iron powder modification. Pour the modified iron powder into the pentaerythritol solution, ultrasonicate for 10 minutes, and volatilize the solvent while stirring in the rotary steamer until the magnetic powder and the binder form a paste slurry; take out the paste sl...

Embodiment 3

[0070] In this example, a white fingerprint revealing powder is prepared, and the specific preparation process is as follows:

[0071]Weigh 4.5 grams of iron powder with an average particle size of 200 μm, 0.45 grams of titanium oxide of 80 nm; 0.18 grams of erythritol, dissolve it with 15 milliliters of methanol at room temperature, and set aside; pour the iron powder into the stirring device, and add 2% lemon The acid solution has not passed the surface of the magnetic powder, start stirring at 100-220rpm, stir for 10-15min, stop stirring and filter, rinse the filter cake with absolute ethanol or methanol for more than three times, take out the filter cake, and dry in a nitrogen atmosphere to complete the transformation of iron powder sex. Pour the modified iron powder into the solution dissolved in erythritol, ultrasonicate for 10 minutes, and volatilize the solvent while stirring in a rotary steamer until the magnetic powder and binder form a paste slurry; take out the pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com