Gantry type self-walking automatic folding and unfolding awning

A self-propelled, gantry-type technology, applied in motor vehicles, vehicles for freight, load coverage, etc., can solve the problems of cumbersome installation, low installation efficiency, inability to open side doors, etc., to reduce production costs, improve installation efficiency, The effect of eliminating security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

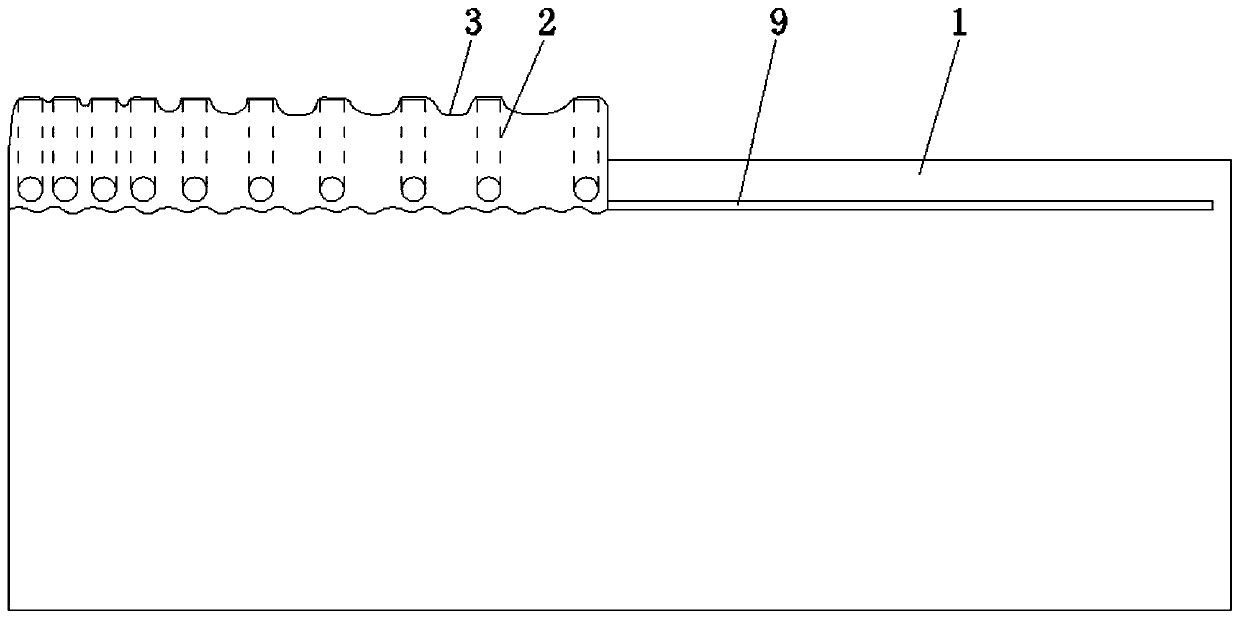

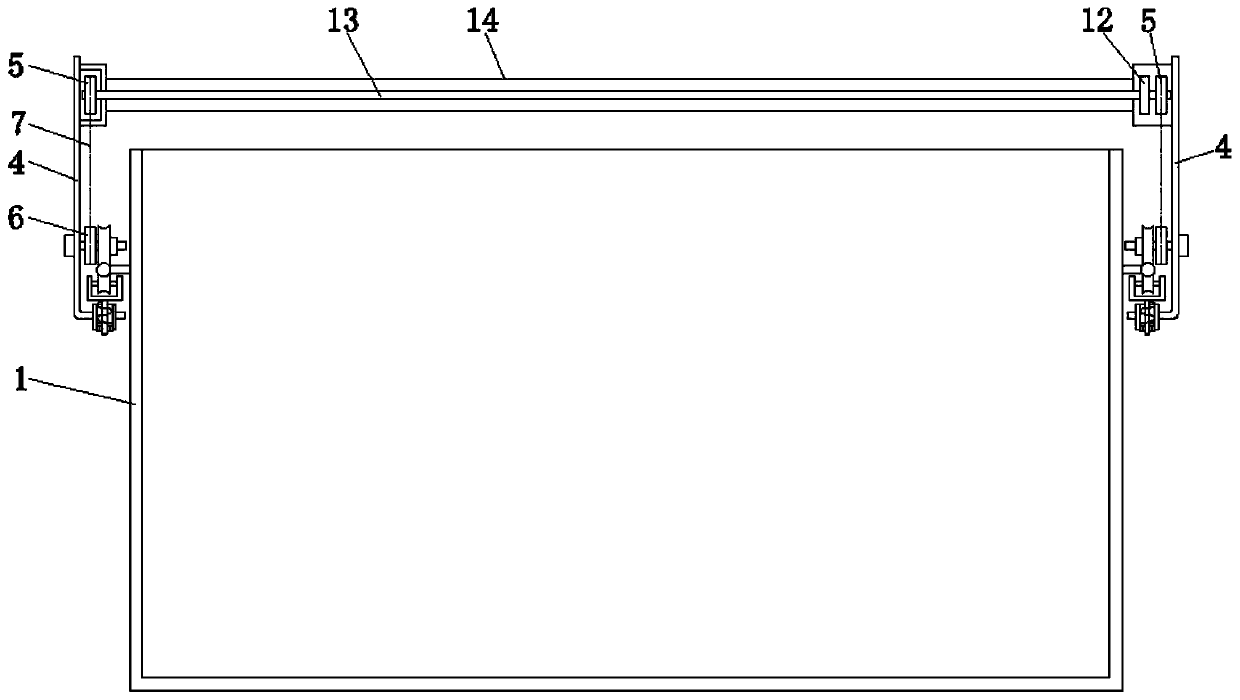

[0031] Such as figure 1 , figure 2 , Figure 4 , Figure 5 As shown, the compartment 1 can be a dump truck compartment with the rear door opened, or a truck compartment with the side door opened. A retractable mechanism 2 is installed on the top of the compartment 1, and the retractable mechanism 2 is covered with a tarpaulin 3. The above-mentioned retractable mechanism 2 adopts the prior art, and its structure and working principle will not be repeated here. Rail 9 is arranged symmetrically on the left and right sides of compartment 1, and track 9 extends from front to back. 1 side panel is fixed.

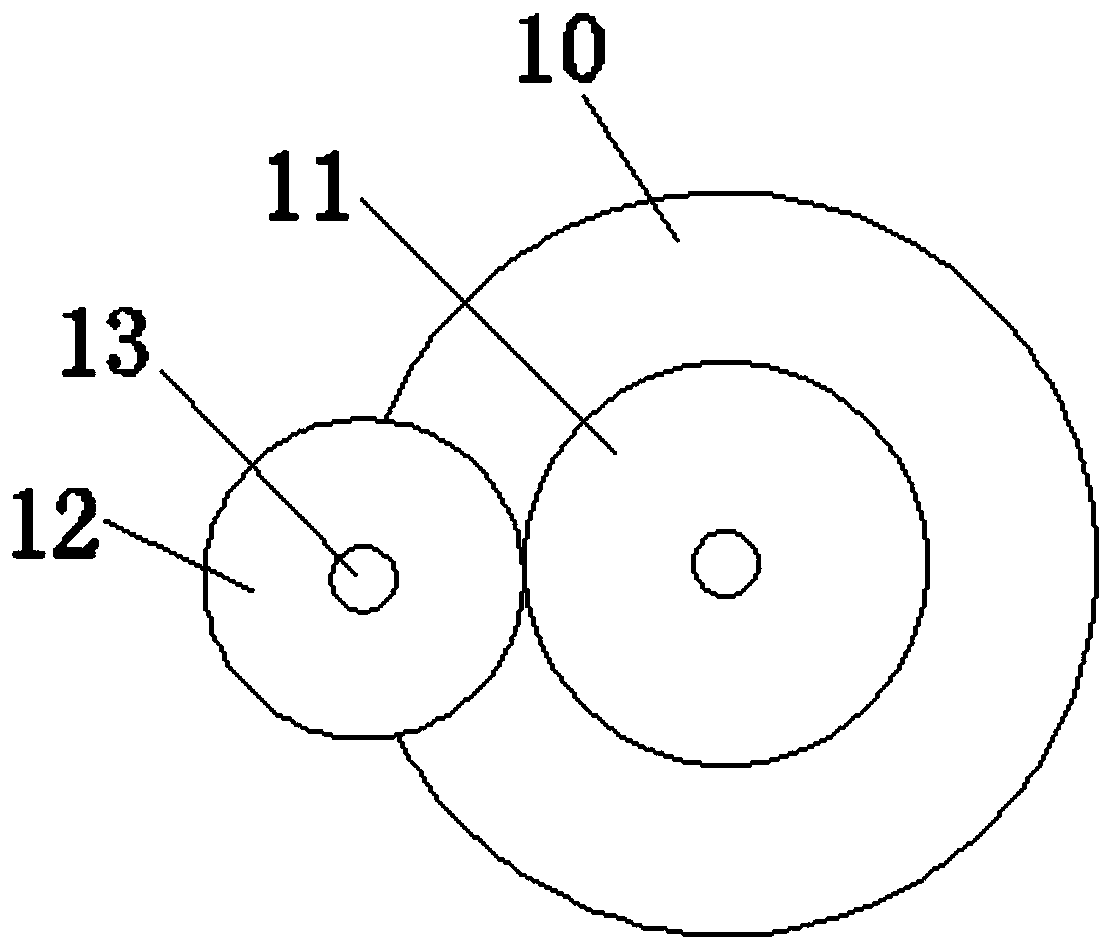

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, vertical boards 4 are also arranged symmetrically on the left and right sides of the compartment 1, the vertical boards 4 are parallel to the side panels of the compartmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com