High-efficiency adhesive sticker label winding machine for non-stop operation

A winding machine and operation technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems that affect the working efficiency of the self-adhesive winding machine and the working efficiency is not high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0105] The present invention will be described below in conjunction with specific embodiments.

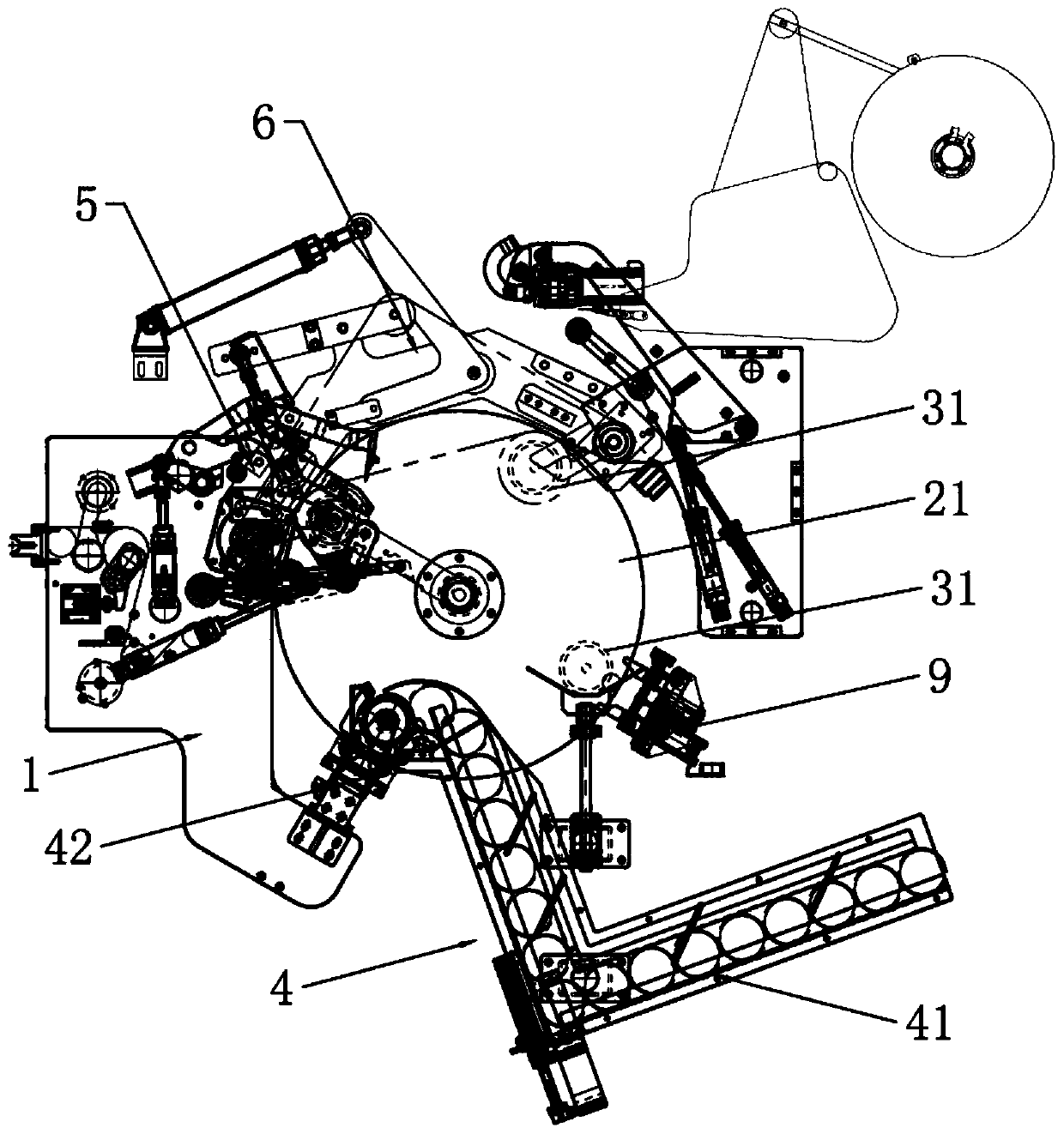

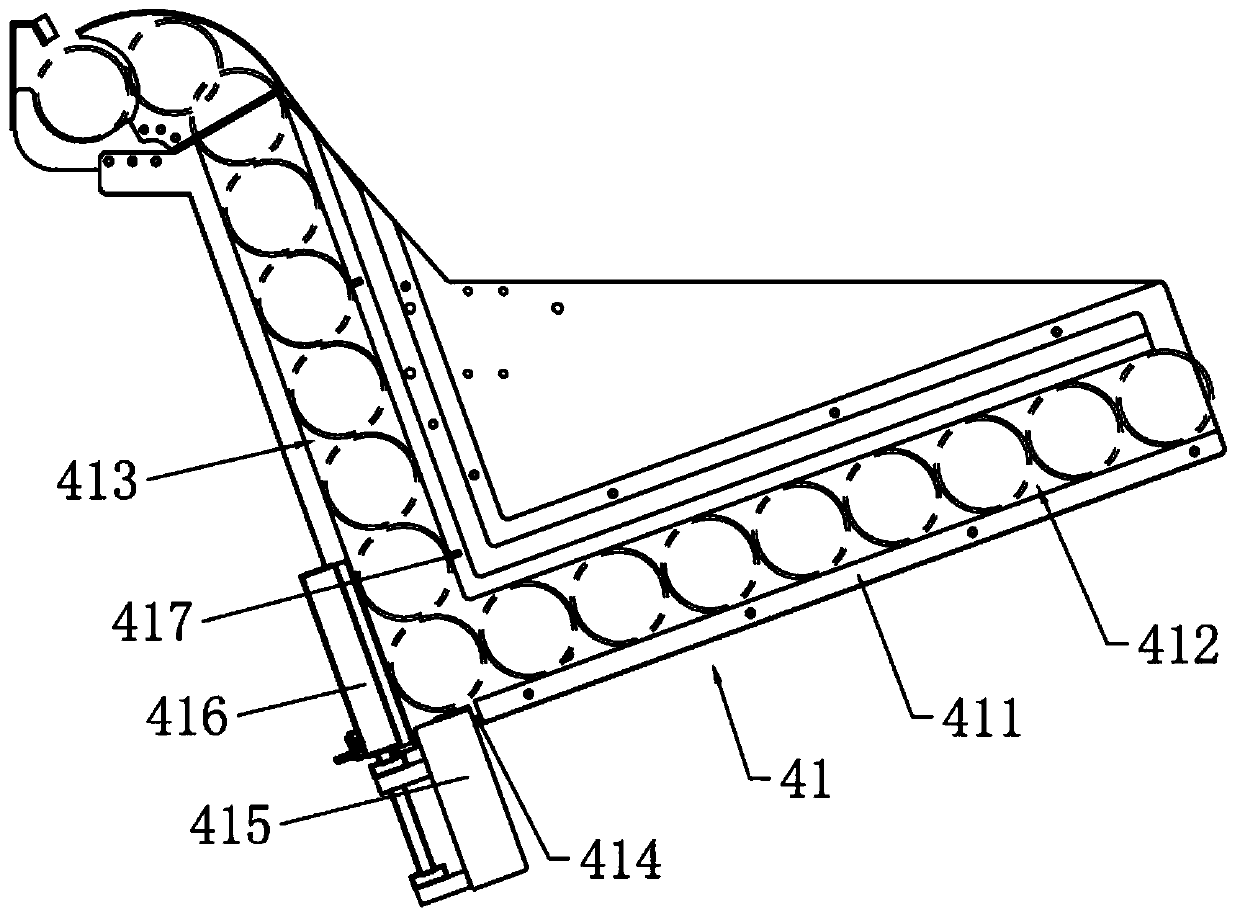

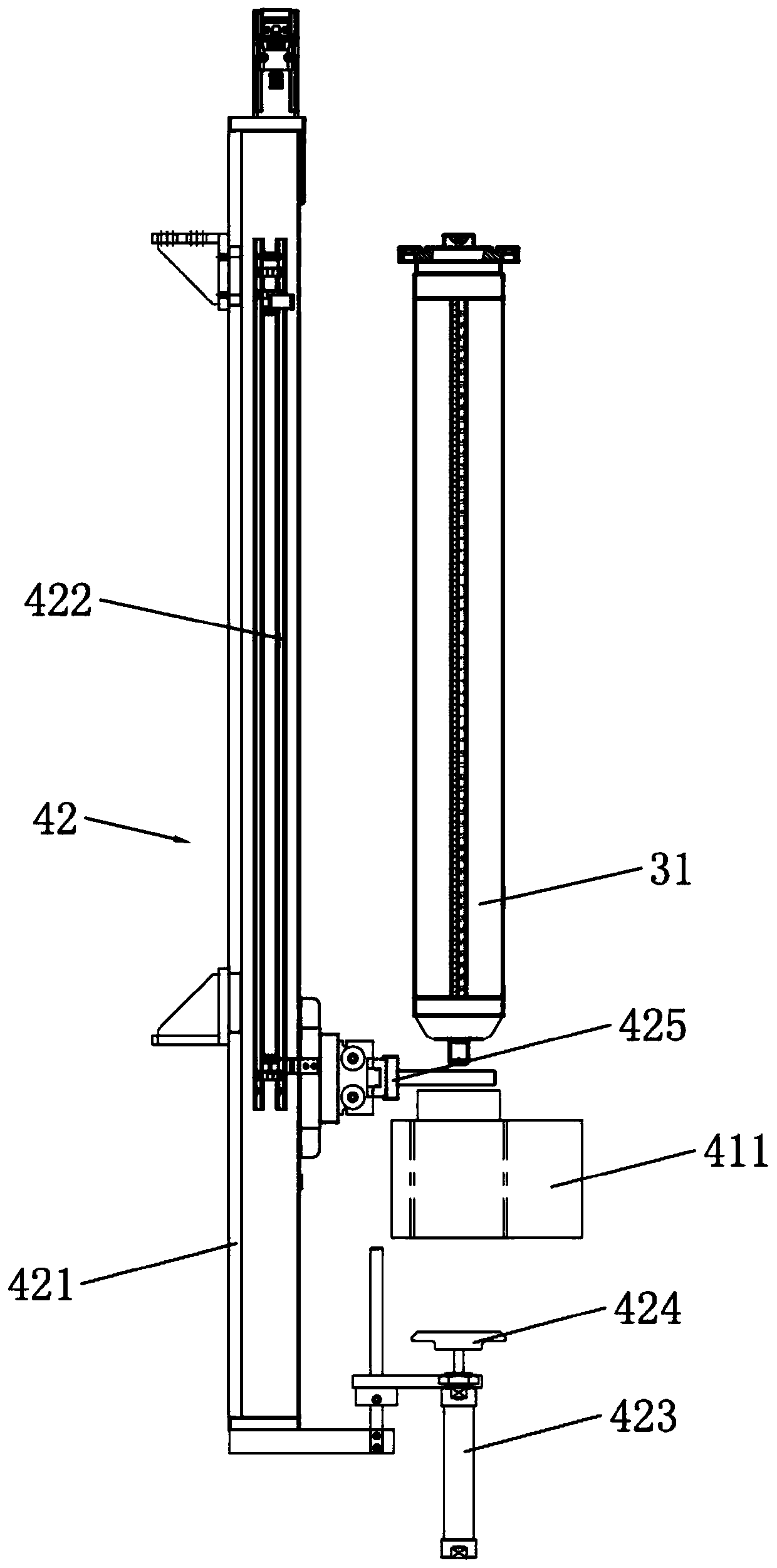

[0106] Such as figure 1 As shown, a self-adhesive label winding machine with high-efficiency non-stop operation includes a frame 1. The frame 1 is equipped with a vertically arranged movable disc 2 that rotates intermittently. The frame 1 corresponds to the movable disc. The disk 2 is equipped with a disk drive mechanism 22, and the disk drive mechanism 22 is drivingly connected with the movable disk 2; the edge of the movable disk 2 is equipped with four rings that are evenly spaced and distributed horizontally along the front and rear directions respectively. Extended rewinding inflatable shafts 31, the movable disk 2 corresponds to each rewinding inflatable shafts 31 are respectively screwed with hollow-shaped inflatable shaft installation sleeve cups 32, and each rewinding inflatable shafts 31 are installed on corresponding In the central hole of the air expansion shaft instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com