Multifunctional polysiloxane thermoplastic elastomer and its preparation method and application

A thermoplastic elastomer and polysiloxane technology, which is applied in the field of thermoplastic elastomers, can solve the problems that composite materials do not have repeatable processing properties, the content of polysiloxane in composite materials should not be too high, and waste of resources, etc., to achieve excellent Effects of thermally induced shape memory function, fast shape recovery rate, and high shape fixation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

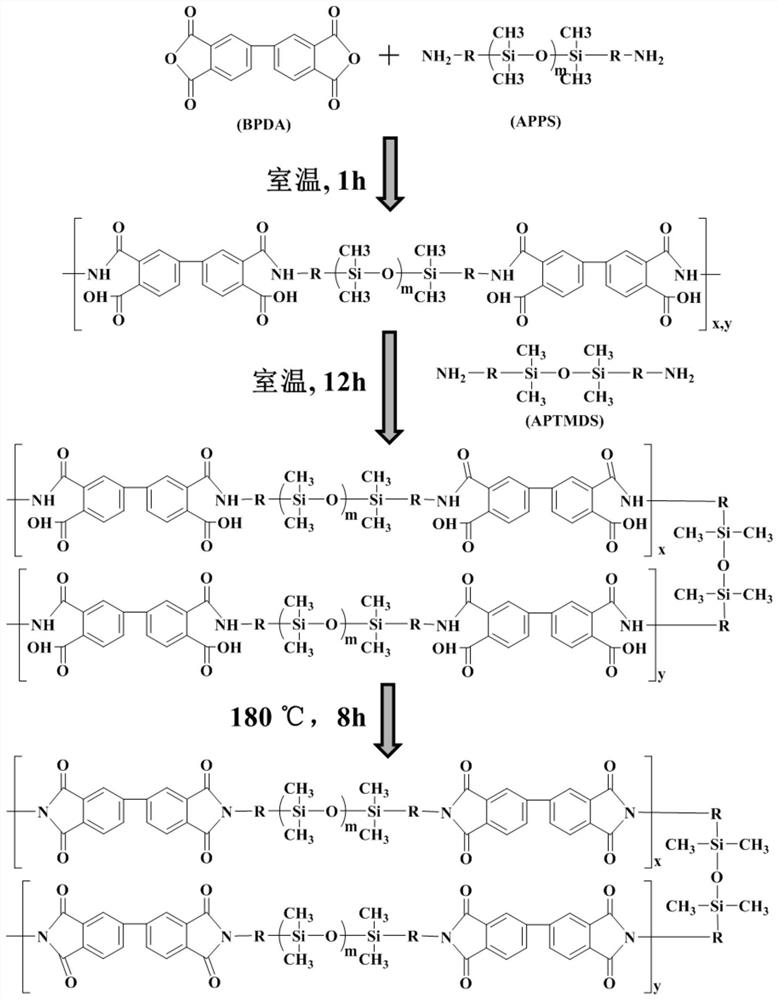

Method used

Image

Examples

Embodiment 1

[0039] (1) Add 127.55g of octamethylcyclotetrasiloxane (0.43mol), 24.85g of 1,3-bis(3-aminopropyl) to a round bottom flask connected with mechanical stirring, reflux condenser and inert protection device - 0.12 g of 1,1,3,3-tetramethyldisiloxane (0.1 mol) and catalyst tetramethylammonium hydroxide (25% methanol solution). Raise the reaction temperature to 80°C and react for 10h under the protection of nitrogen; then raise the temperature to 150°C and react for 1.2h to decompose the catalyst to obtain a crude product; finally, distill under reduced pressure in a rotary evaporator at 150°C for 2h to remove small molecular substances , to obtain a colorless and transparent double-terminated aminopolysiloxane named APPS-1500.

[0040] (2) Add 3.71g of 3,3',4,4'-biphenyltetracarboxylic dianhydride (12.6mmol) in a double-necked round-bottomed flask equipped with a constant pressure dropping funnel and an inert protection device. 1,3-bis(3-aminopropyl)-1,1,3, The o-dichlorobenzene ...

Embodiment 2

[0043] In addition to 3,3',4,4'-biphenyltetracarboxylic dianhydride, APPS-1500 and 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyl The feeding molar ratio of disiloxane is 17.8:10:7, the temperature of hot pressing in step 3 is 90°C, and the rest are the same as in Example 1.

Embodiment 3

[0045] In addition to 3,3',4,4'-biphenyltetracarboxylic dianhydride, APPS-1500 and 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyl The feeding molar ratio of disiloxane is 23.1:10:12, the temperature of hot pressing in step 3 is 100°C, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com