A 4.5um ultra-thin electrolytic copper foil preparation device and its preparation process

A technology of electrolytic copper foil and preparation process, applied in the direction of electrolysis process and electroforming, can solve the problems of copper foil wrinkling and copper foil breakage, and achieve the effect of improving tensile strength and elongation, and facilitating adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

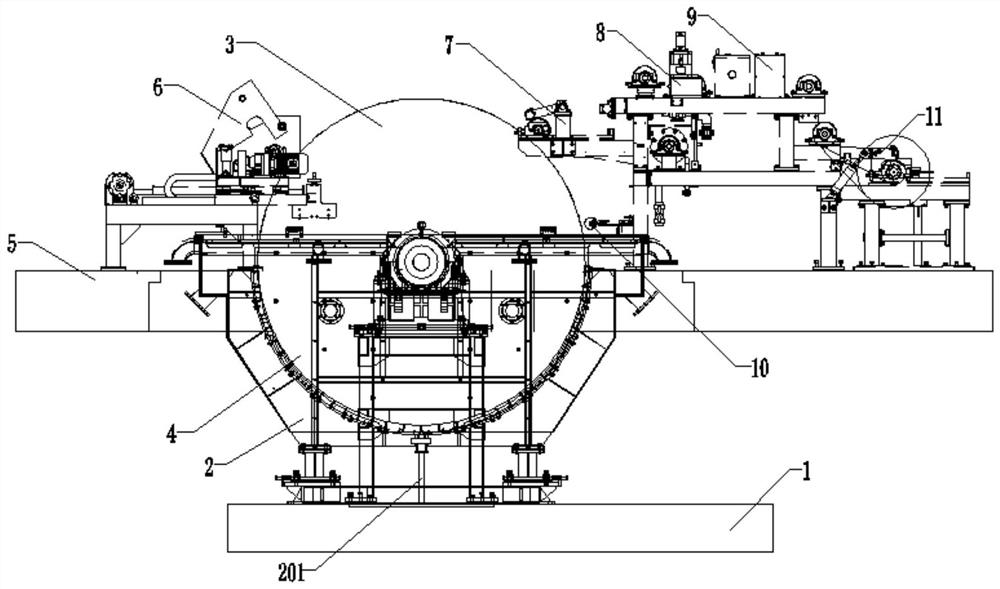

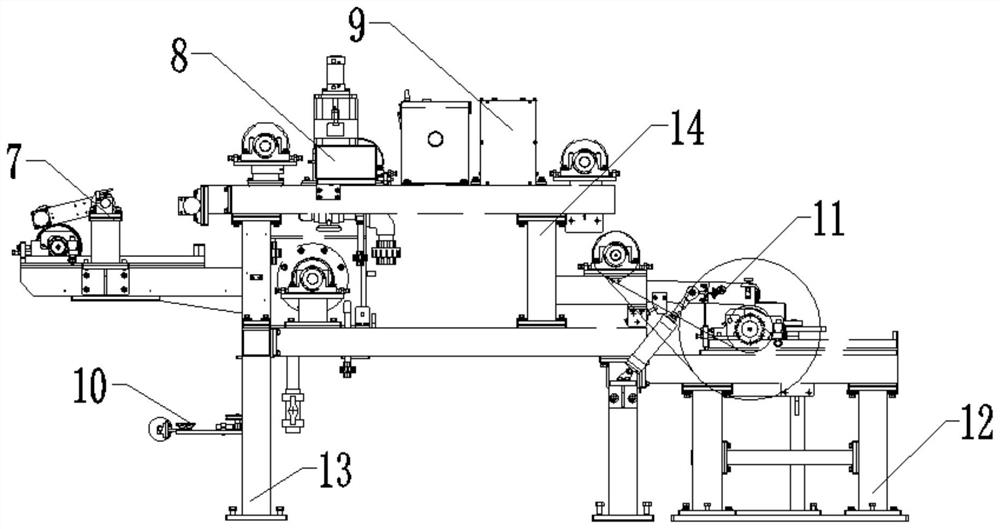

[0052] see Figure 1-4 As shown, the present invention achieves the above object through the following technical scheme, a preparation device of 4.5um ultra-thin electrolytic copper foil, comprising an anode tank base platform 1, the top of the anode tank base platform 1 is connected with a support seat 2, and supports A cathode roller 3 is rotatably connected to the seat 2, and an anode tank mechanism 4 is arranged between the cathode roller 3 and the supporting seat 2.

[0053] The top of the support base 2 is provided with a second-layer table top 5, and the second-layer table top 5 is respectively provided with a brushing mechanism 6, a peeling and trimming mechanism 7, an anti-oxidation mechanism 8, a drying fan cooling mechanism 9, a water washing mechanism 10 and a winding mechanism 11.

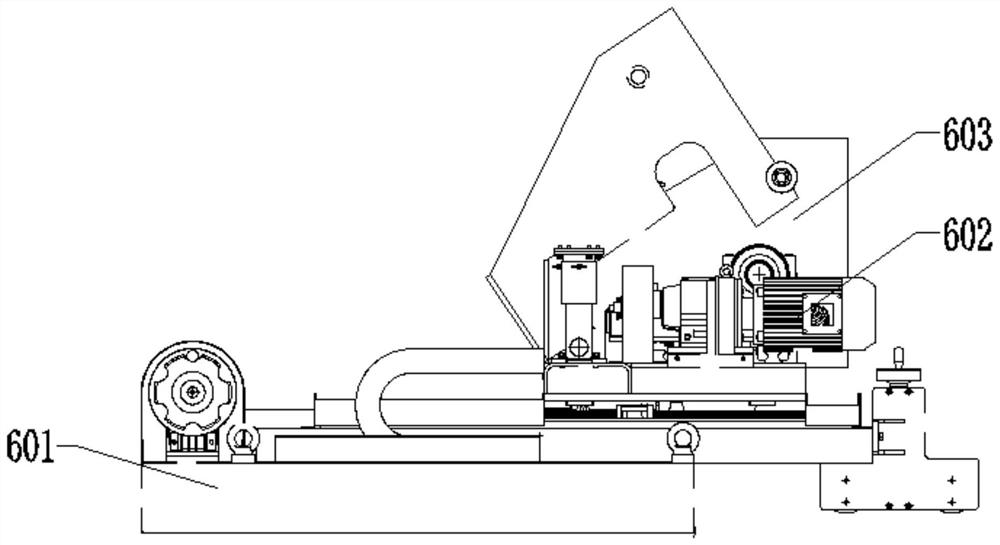

[0054] The top of the second-floor platform 5 is connected with a first support frame 601 , on which a support block 603 is slidably connected by a reciprocating drive motor 602 , and...

Embodiment 2

[0063] A preparation process of 4.5um ultra-thin electrolytic copper foil, which adopts the preparation device of embodiment 1, comprising the following steps:

[0064] S1, cutting the electrolytic copper into strips or blocks before loading into the copper melting tank;

[0065] S2, put the copper material into a copper-dissolving tank with high solvency, add sulfuric acid and pure water to prepare a sulfuric acid solution, and then blow air into the copper-dissolving tank;

[0066] S3, performing multi-stage filtration to the copper sulfate solution configured in step S2;

[0067] S4, the prepared copper sulfate solution is pumped from the supply liquid to a fully-sealed high-level tank and cooled by a heat exchanger for standby. The copper sulfate solution is transported by a pipeline, and the flow of the electrolyte is adjusted through a valve;

[0068] S5, electrolyzing the copper foil, and adding additives in the electrodeposition tank during electrolysis;

[0069] S6,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com