A kind of forged steel soft seal floating ball valve

A floating ball valve and soft seal technology, applied in shaft seal, valve details, valve device, etc., can solve the problems of floating ball valve control flow rate changes, different rotation angles, and maintenance personnel are easy to touch the valve by mistake, so as to prevent accidental touch the effect of the situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

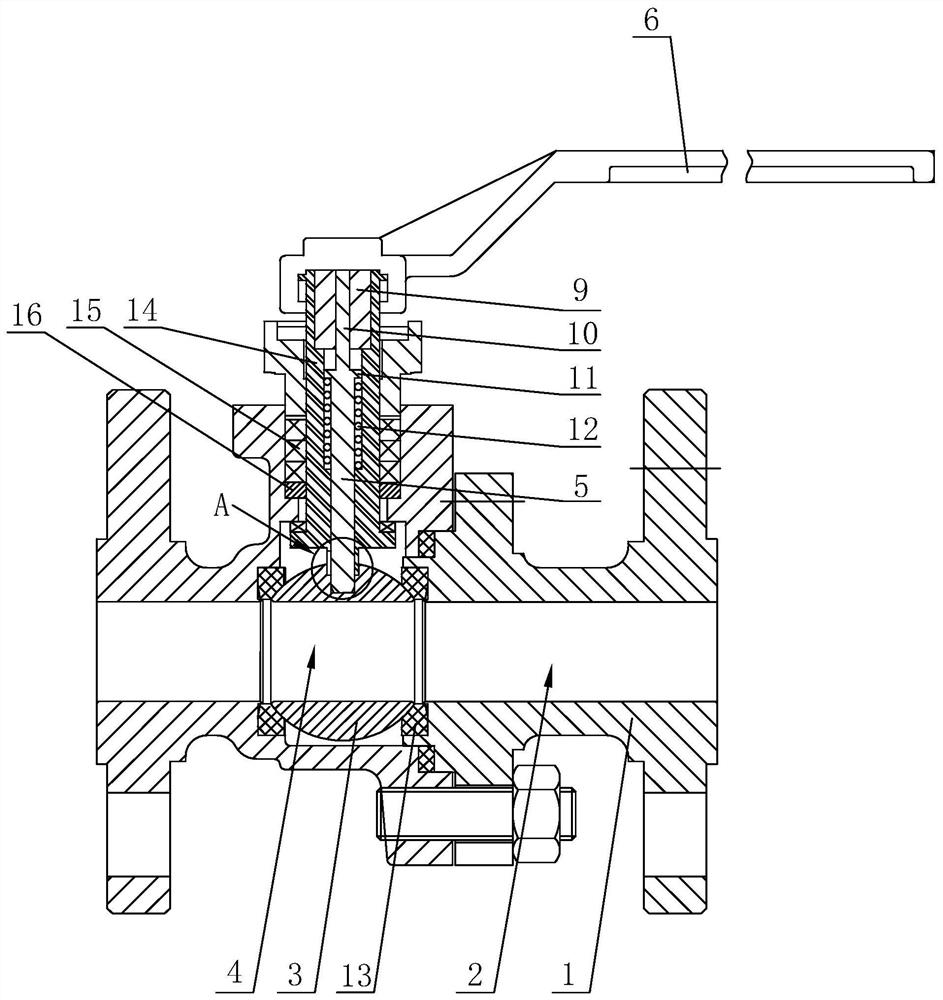

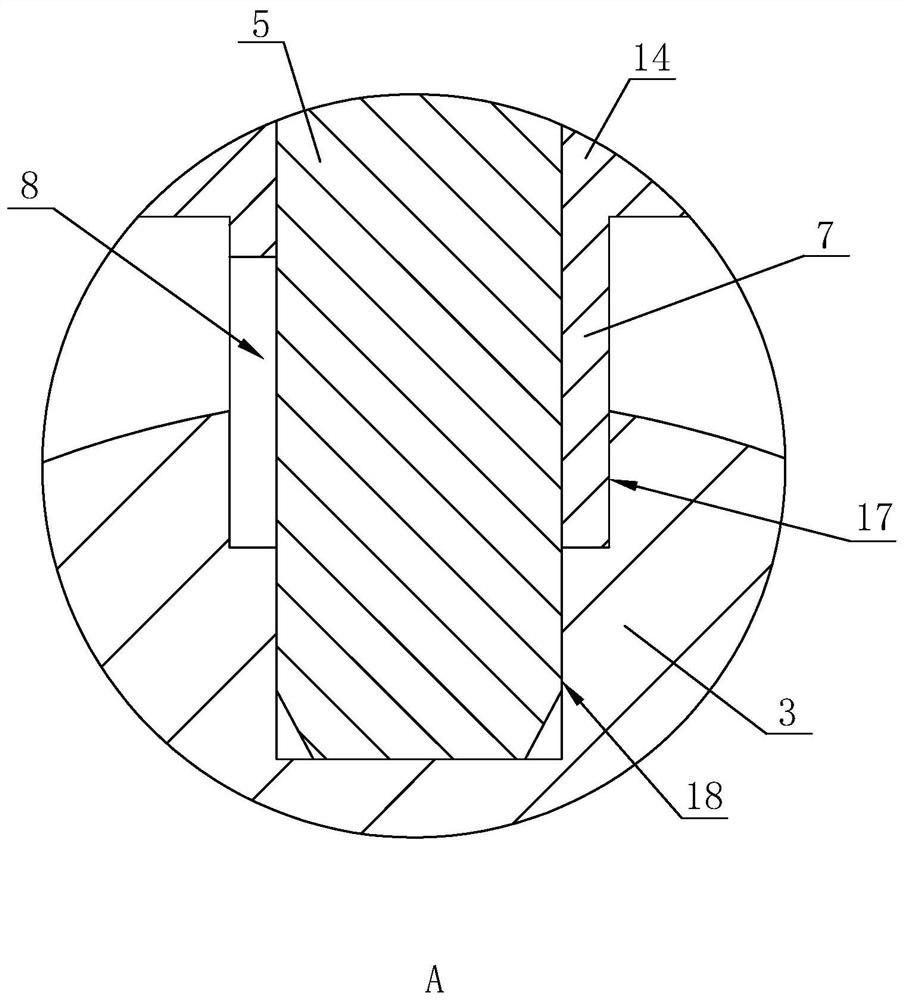

[0034] A forged steel soft seal floating ball valve, such as figure 1 and figure 2 As shown, the valve body 1 is included, and a flow channel 2 is opened through the valve body 1. The valve body 1 is rotatably connected with a valve ball 3 in the flow channel 2, and a valve hole 4 is opened on the valve ball 3. When in use, the flow channel 2. The internal fluid is liquid or gas. By rotating the valve ball 3, the valve hole 4 is misaligned with the flow channel 2, so as to realize the adjustment or cut-off of the flow. Both ends of the valve hole 4 on the valve ball 3 in the valve body 1 are fixed with sealing valve seats 13 , and the position limitation and sealing of the valve ball 3 are realized through the sealing valve seats 13 .

[0035] A rotating sleeve 14 is rotatably connected to one side of the valve body 1 and the valve ball 3, and a packing 15 and a packing pad 16 are also arranged between the rotating sleeve 14 and the valve body 1 to realize the smooth rotatio...

Embodiment 2

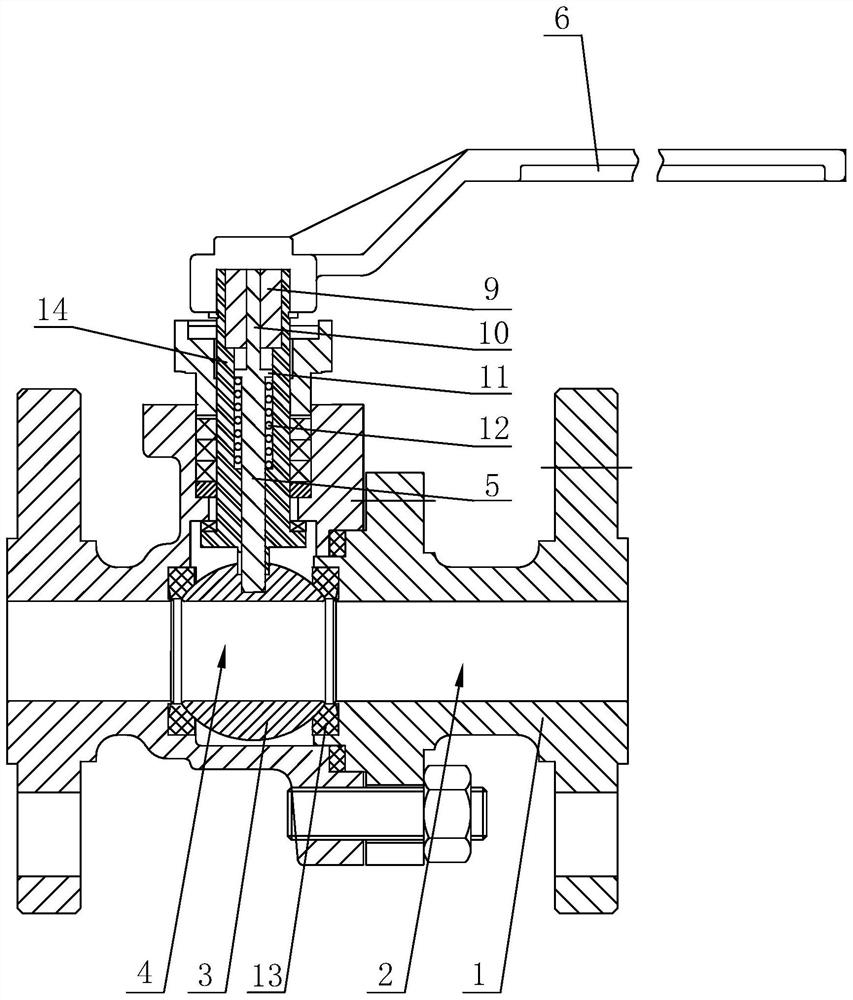

[0042] A forged steel soft seal floating ball valve, such as image 3 As shown, the difference from Embodiment 1 is that the end of the rotating sleeve 14 away from the valve ball 3 is set in a regular hexagonal shape, and one end of the valve handle 6 is plug-fitted with the end of the rotating sleeve 14 away from the valve ball 3 . A plurality of floating ball valves can be adjusted by using one valve handle 6, so as to avoid affecting maintenance operations due to the existence of the valve handle 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com