Waterproof sleeve for water-immersed motor wiring and using method thereof

A waterproof cover and water immersion technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as leakage, potential safety hazards of joints, economic losses, etc., and achieve the effects of avoiding leakage problems, beautiful volume, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

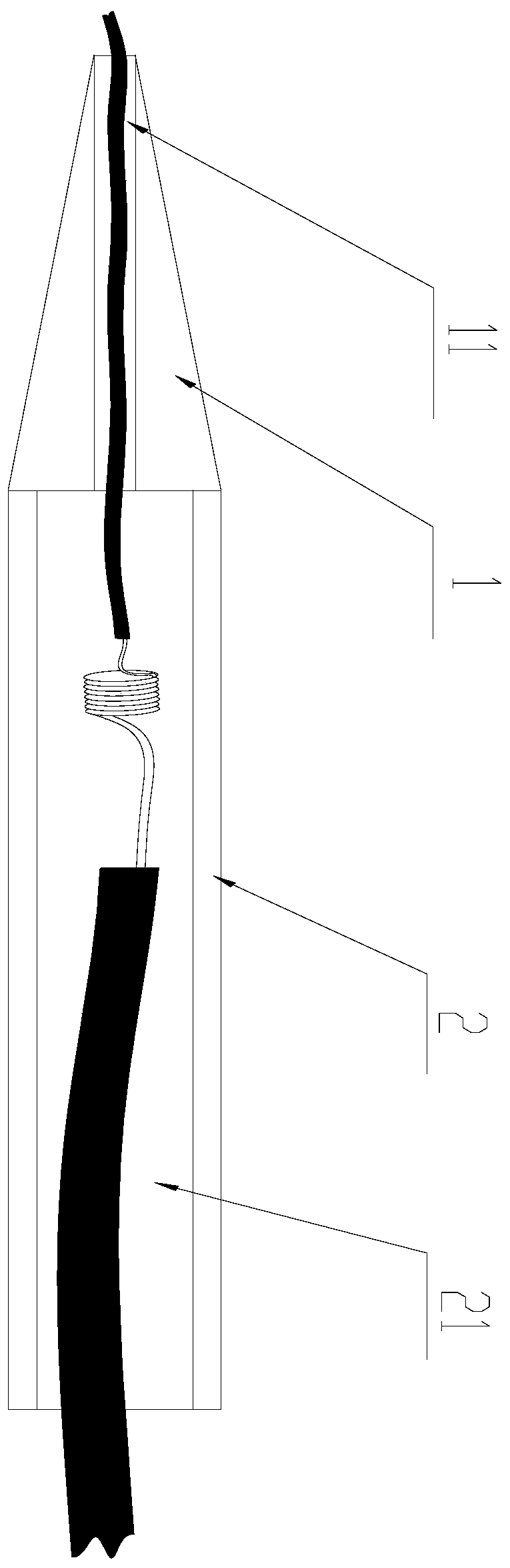

Embodiment 1

[0031] This embodiment provides a waterproof sleeve for water-immersed motor wiring, such as figure 1 As shown, it includes the electromagnetic wire penetration cylinder 1 and the connector protection cylinder 2. Both the magnet wire penetration cylinder 1 and the joint protection cylinder 2 are made of high-strength waterproof insulating rubber material, which has good insulation performance and can maintain a stable state for a long time in water , will not expand due to moisture, the electromagnetic wire penetration tube 1 is a tapered cylindrical structure, including a small diameter end and a large diameter end, and a through small hole 11 opened inside it, and the joint protection tube 2 is cylindrical structure, which includes a connection end and a free end, and a large through-hole 21 opened inside, and the electromagnetic wire penetration cylinder 1 and the joint protection cylinder are formed into one through the fixed connection between the large-diameter end and th...

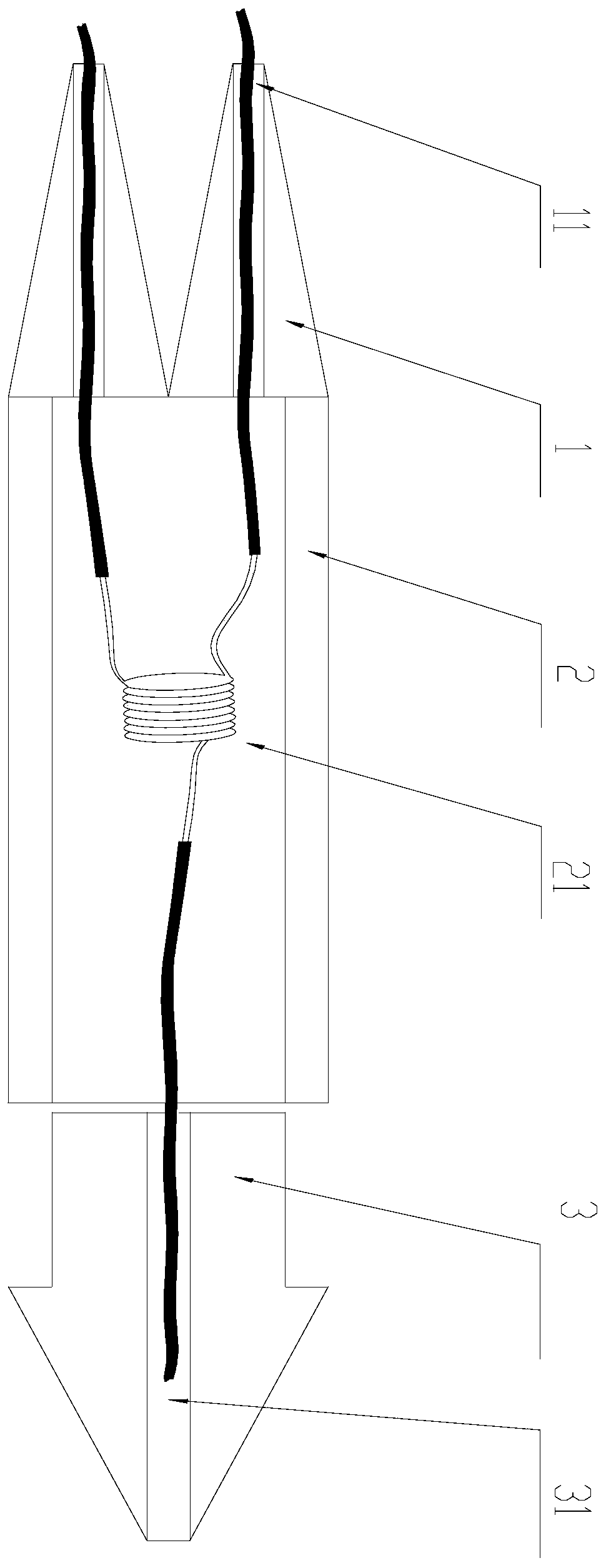

Embodiment 2

[0035] For the three star-point connection electromagnetic wires, this embodiment provides another implementation of the waterproof sleeve for the connection of the water-immersed motor, such as figure 2 As shown, the number of electromagnetic wire penetration cylinders 1 is 2, the number of joint protection cylinders 2 is 1, the number of large holes 21 in the joint protection cylinder 2 is 1, and the number of two electromagnetic wire penetration cylinders 1 is fixed side by side. The large-diameter end of the joint protection tube 2 is connected to the connection end of the joint protection tube 2, and two small holes 11 and one large hole 21 are correspondingly set through. It has a cylindrical structure, and the other end is a tapered cylindrical structure, and a penetrating tail tube channel 31 is provided in the tail tube 3. The outer diameter of the cylindrical end of the tail tube 3 and the inner diameter of the free end of the joint protection tube 2 form a clearance...

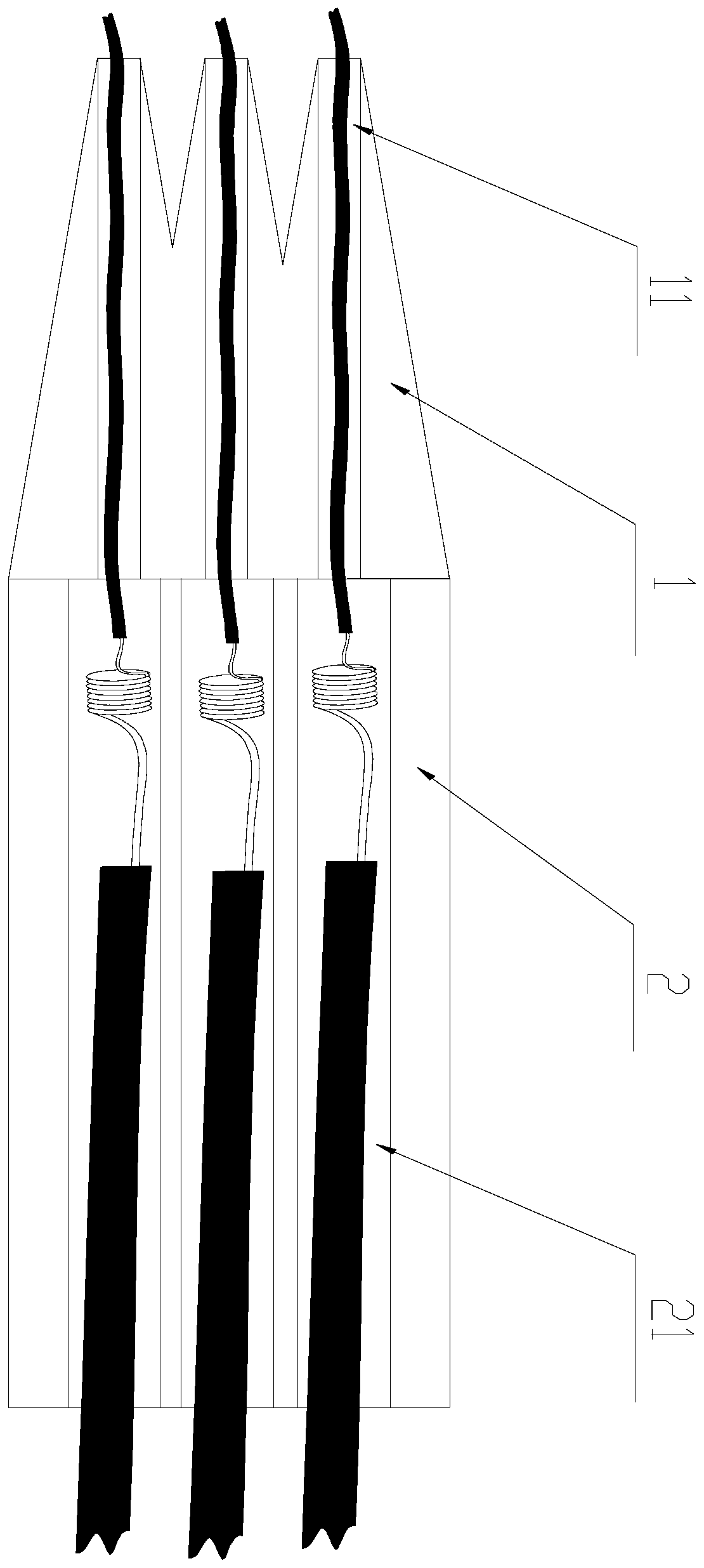

Embodiment 3

[0038] For the connection of three electromagnetic wires and one cable, this embodiment provides another implementation of the waterproof sleeve for wiring of a water-immersed motor, such as image 3 As shown, the number of electromagnetic wire penetration cylinders 1 is three, the number of joint protection cylinders 2 is one, the number of large holes 21 in the joint protection cylinder 2 is three, and the three electromagnetic wire penetration cylinders 1 are fixed side by side and the three The large-diameter end of the connector is connected to the connection end of the joint protection cylinder 2, and the three small holes 11 are respectively connected with the three large holes 21.

[0039] The method of use is as follows: the three electromagnetic wires are respectively inserted into the small hole 11 through the small diameter end of the electromagnetic wire into the cylinder 1, and respectively penetrated through the small hole 11 to the large hole 21 of the joint pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com