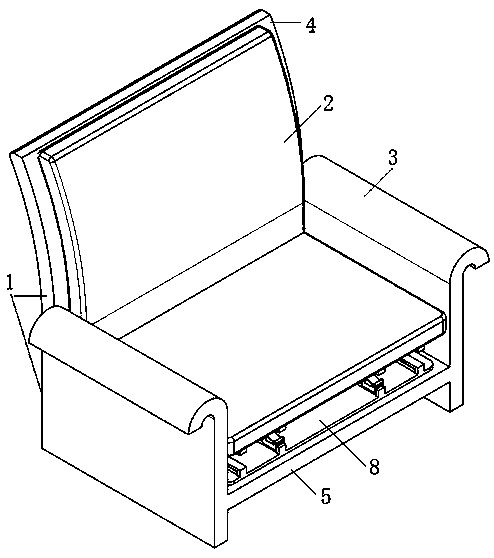

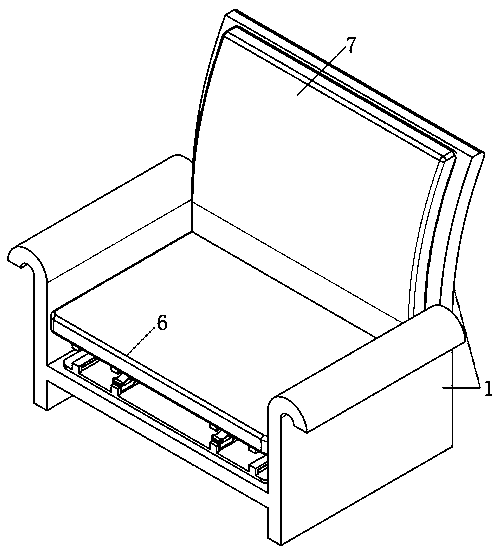

Multi-channel aeroelastic sofa with bionic cushioning layer

A cushioning layer and multi-channel technology, applied in the field of furniture, can solve the problems of inability to move up and down as a whole for cushioning, discounting the rebound effect of fillers, reducing body contact pressure, etc., to increase wrapping performance, good displacement response effect, increase The effect of the force area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

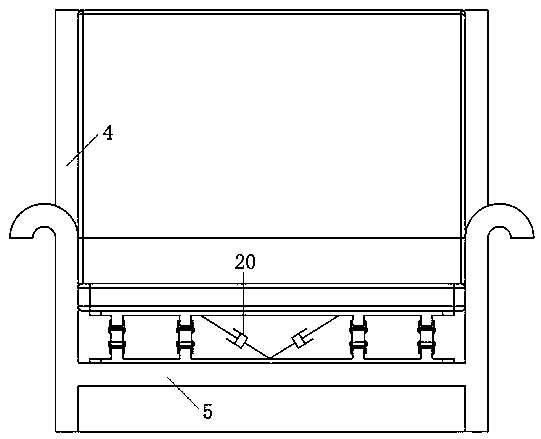

[0041] The base plate 12 and the top plate 13 of the bionic cushioning layer 8 are respectively made of hardwood structure, the space between the T-shaped slideway 14 and the parallel slider 15 is frosted and coated with wear-resistant rubber to increase friction, and the leaf spring 17 is made of hard alloy , the ratio of the stiffness of the leaf spring 17 to the stiffness of the tension spring 19 is 16:1, the length of the parallel slider 15 is 3 times the width of the parallel slider 15; the rubber airbag 10 is flat, and the thickness of the rubber airbag 10 is 1.5mm , the length and width of the rubber airbag 10 are 5cm, and the rubber airbag 10 is connected to form a triangular grid structure. The rubber airbag 10 is provided with an elastic sheet of the scissors foot structure, which is used to restore the shape of the rubber airbag 10. Between the rubber airbag 10 The diameter of the pipeline between them is 3mm; the opening of the valve 11 is marked linearly and steple...

Embodiment 2

[0043] The base plate 12 and the top plate 13 of the bionic cushioning layer 8 are made of light alloy structure respectively, lubricating oil is used between the T-shaped slideway 14 and the parallel slider 15 to increase the lubricating effect, and two cable-stayed cables are arranged obliquely between the base plate 12 and the top plate 13 The damper 20 of the structure, the leaf spring 17 adopts spring steel, the ratio of the stiffness of the leaf spring 17 to the stiffness of the extension spring 19 is 9:1, the length of the parallel slider 15 is twice the width of the parallel slider 15, and the rubber airbag 10 For flat shape, the thickness of rubber air bag 10 is 2mm, and the length and width of rubber air bag 10 are 5cm, and the rubber air bag 10 is connected to form a circular grid structure, and the rubber air bag 10 is provided with an elastic sheet of scissors foot structure. To restore the shape of the rubber airbags 10, the diameter of the pipes between the rubbe...

Embodiment 3

[0045] The base plate 12 and the top plate 13 of the bionic cushioning layer 8 are made of light alloy structure respectively, lubricating oil is used between the T-shaped slideway 14 and the parallel slider 15 to increase the lubricating effect, and two cable-stayed cables are arranged obliquely between the base plate 12 and the top plate 13 The damper 20 of the structure, the leaf spring 17 adopts hard alloy, the ratio of the stiffness of the leaf spring 17 and the stiffness of the extension spring 19 is 20:1, the length of the parallel slider 15 is 2.5 times the width of the parallel slider 15, and the rubber airbag 10 is flat, the thickness of rubber airbag 10 is 2mm, the length and width of rubber airbag 10 are 3cm, and the rubber airbags 10 are connected to form a quadrilateral grid structure. In order to restore the shape of the rubber airbags 10, the diameter of the pipes between the rubber airbags 10 is 2 mm, the opening of the valve 11 is marked linearly and steplessl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com