Grinding and polishing device for rear cases of electronic watches

An electronic watch and optical device technology, which is applied to grinding driving devices, grinding/polishing equipment, grinding machines, etc., can solve the problems of incapable of multi-directional displacement of the polishing head, wasting time, affecting the efficiency of polishing, etc., saving manpower, The effect of improving polishing quality and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

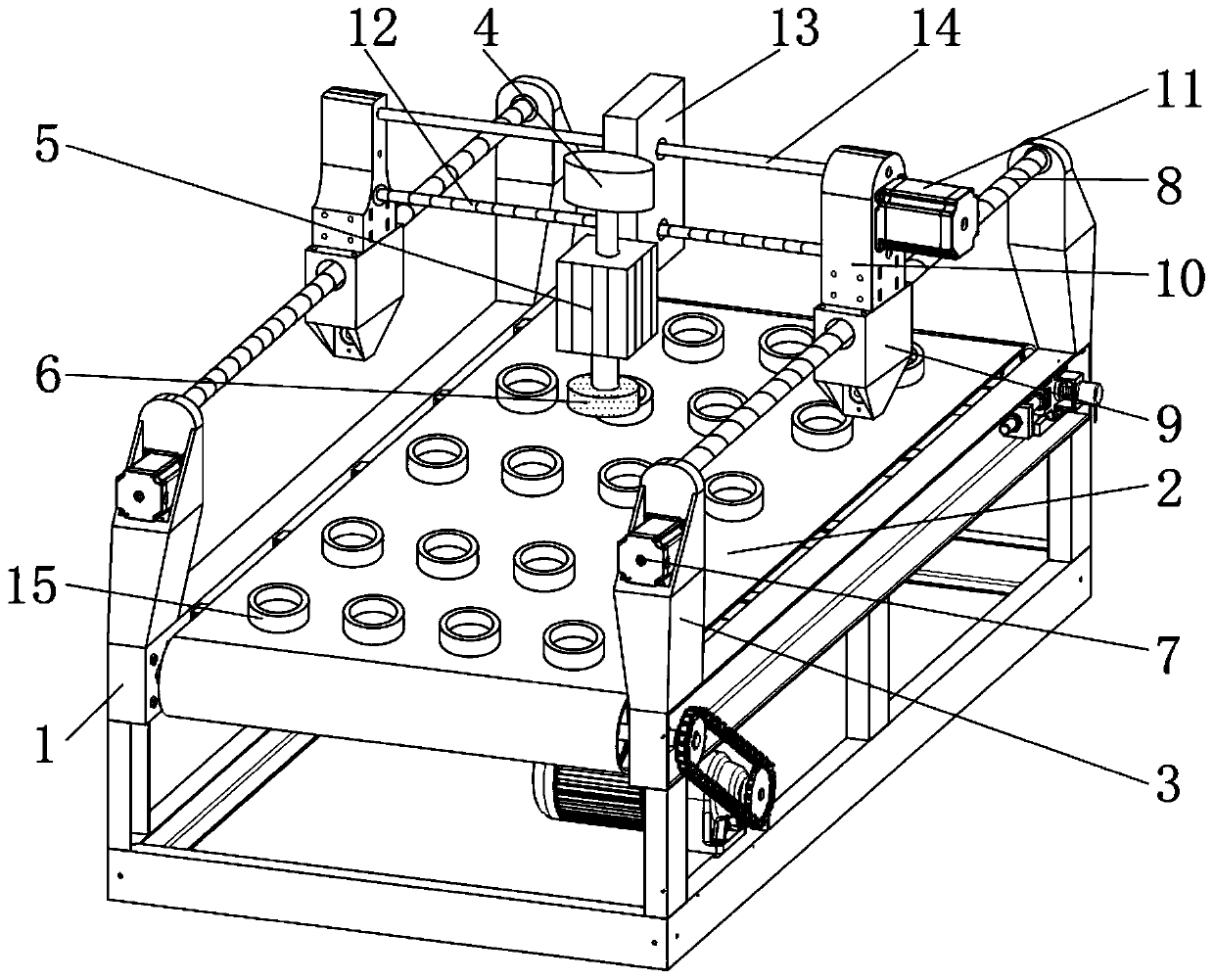

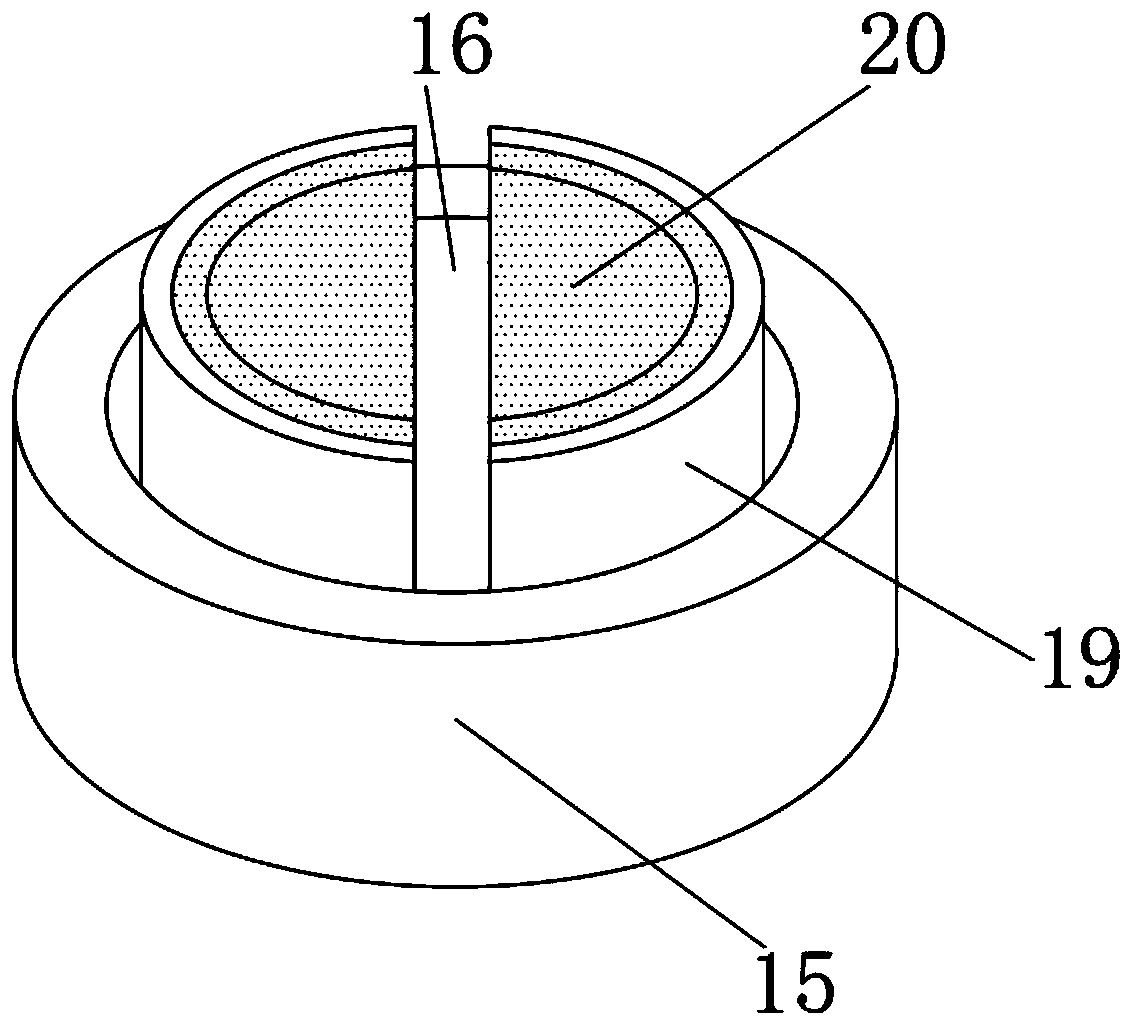

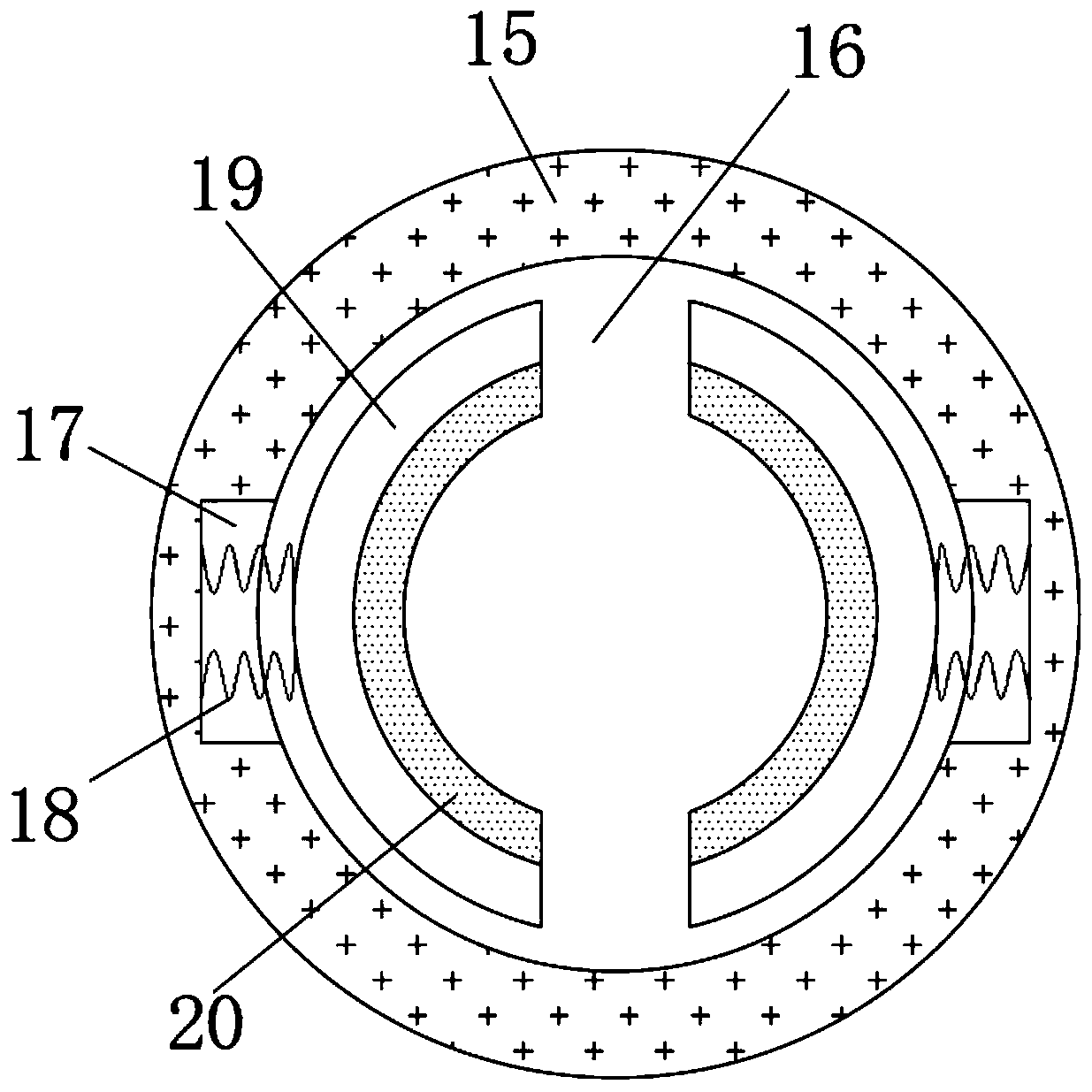

[0019] see Figure 1~3 , in the embodiment of the present invention, a kind of device that is used for polishing the rear case of electronic watch, comprises frame 1, is fixedly connected with conveyor 2 on frame 1, and conveyor 2 can also make circular seat 15 displacement, is convenient for staff Replace the back case of the watch, and the four corners of the frame 1 are respectively fixedly connected with four symmetrically arranged uprights 3, and the four uprights 3 are fixedly connected with two Y-axis slide rail devices arranged in parallel, and the Y-axis slides The X-axis slide rail device is slidably connected to the rail device to realize the multi-directional displacement of the polishing head 6, so that the polishing head 6 can continuously polish and polish the watch back cover, which solves the need for the polishing head 6 to stop working when replacing the back case In order to improve the processing efficiency, one end of the X-axis slide rail device is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com