Broach type bridge telescopic device and construction method thereof

A telescoping device and comb-tooth-type technology, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as car crashes, large-tooth plate warping, and easy warping, so as to improve service life and reliability, Easy installation and replacement, anti-bounce and upturning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

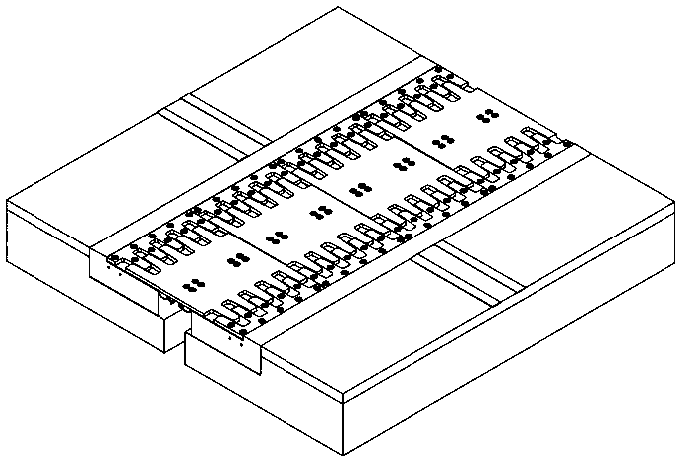

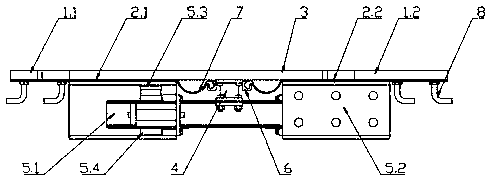

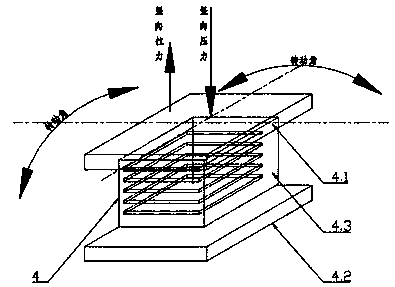

[0045] like Figure 1-6 As shown, a comb-toothed bridge telescopic device includes: middle tooth plate 3 across the seam; side tooth plate 1.1 / 1.2 The side tooth plate is symmetrically arranged on both sides of the middle tooth plate 3 across the seam; the first plate 2.1 / 2.2 , the first plate 2.1 / 2.2 is fixed under the side tooth plate 1.1 / 1.2; the displacement control assembly 5, the displacement control assembly 5 includes a displacement control beam 5.1 and a displacement control box 5.2, and the displacement control assembly 5 is set Under the first plate 2.1 / 2.2 and the middle tooth plate 3; the two sides of the middle tooth plate 3 are interlaced with the side tooth plate 1.1 / 1.2, and the middle tooth plate 3 is set on the first Above the plate 2.1 / 2.2; the elastic element 4, the elastic element 4 is composed of the upper steel plate 4.1, the lower steel plate 4.2 and the rubber body 4.3 between the upper steel plate and the lower steel plate, the rubber body 4.3 is con...

no. 2 example

[0058] The strip seat plate 6 in this embodiment is integrally formed along the length direction of the bridge telescopic device. Other structural settings are consistent with those in the first embodiment. That is, the installed bridge expansion assembly along the length direction of the bridge expansion device may include multiple middle tooth plates 3 , multiple corresponding elastic elements 4 , displacement control components 5 , side tooth plates 1 and first plates 2.1 / 2.2.

[0059] For the construction method of the comb-shaped bridge expansion device, the following steps can be used for construction and installation:

[0060] 1) Pre-assembly: The bridge telescopic device is assembled in the workshop according to the complete set of units, the rubber strip is the entire length, reassembled on site, and then transported to the construction site to wait for installation.

[0061] 2) Place the bridge expansion device on site: place the pre-assembled bridge expansion devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com