Ampoule bottle washing, wetting, filling and sealing integrated device

An ampoule bottle, moisturizing and filling technology is applied in the field of ampoule bottle washing, moisturizing, filling and sealing integrated device field, which can solve the problems of loss of packaged samples, high cost, and inability to guarantee the same heating time and temperature of the ampoules bottle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

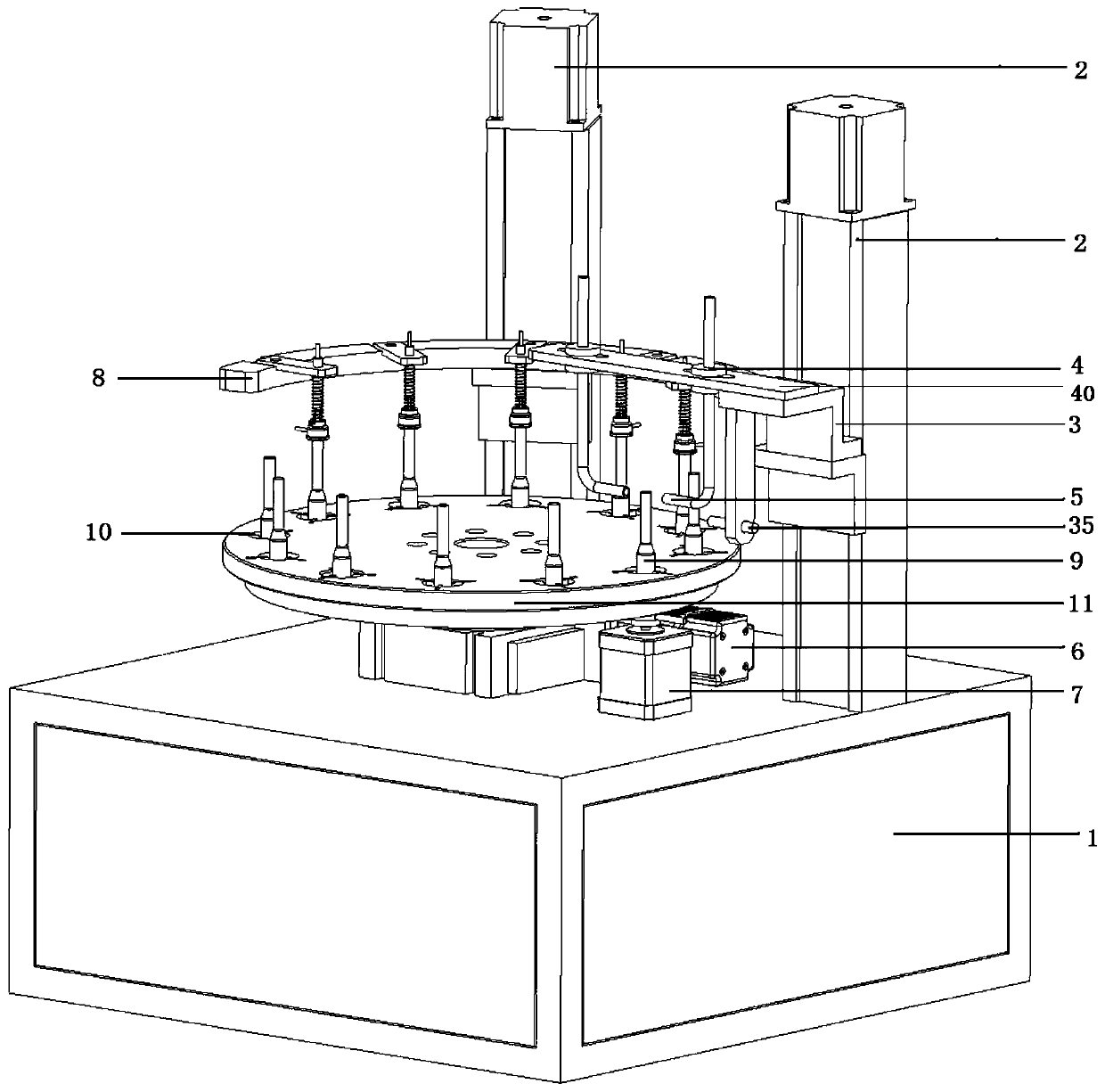

[0052] Such as Figure 1-Figure 6 As shown, an ampoule bottle washing, moisturizing, filling and sealing integrated device includes a main machine casing 1, an annular fixed disk 24, a disk-shaped turntable 11, a turntable drive motor 6, and washing and moisturizing devices arranged in sequence along the rotation direction of the turntable 11. Filling system and rotary fusing sealing system, two stepping motor screw slides 2 for installing the integrated washing and filling system and rotary fusing sealing system respectively.

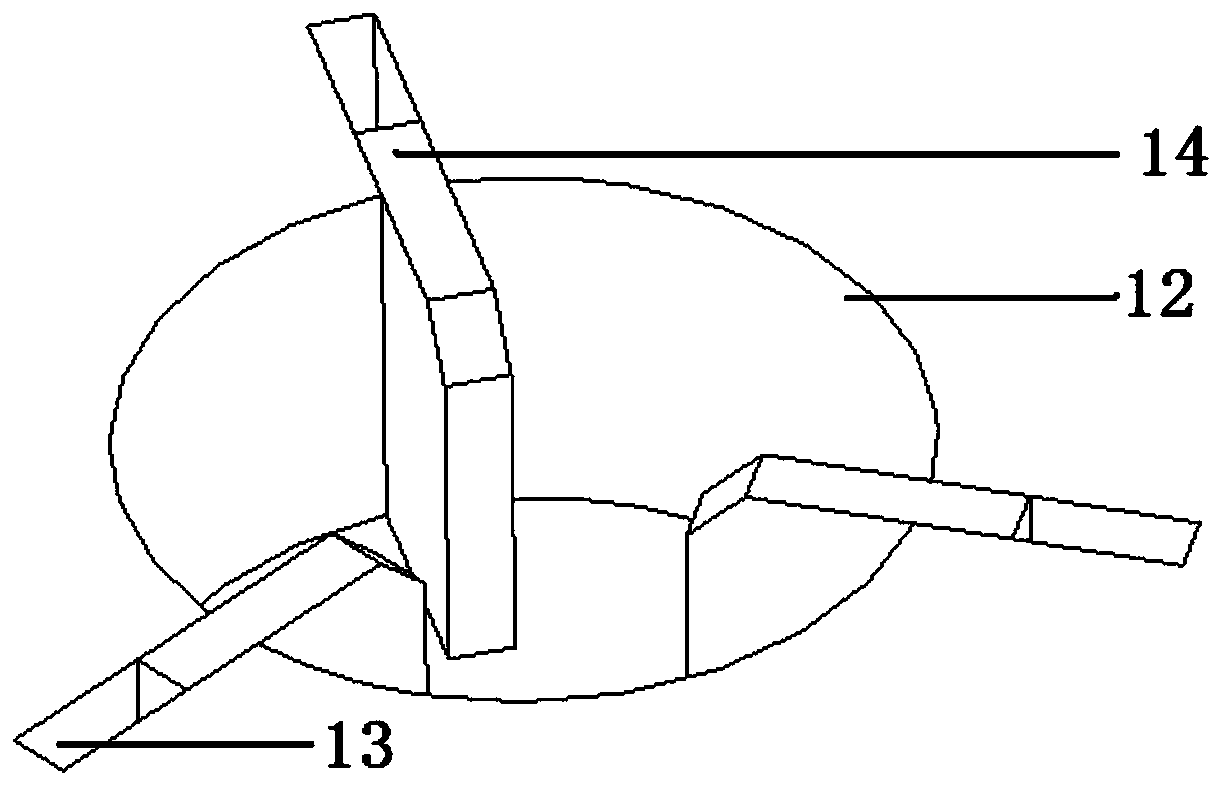

[0053] The fixed disk 24 is fixed on the main machine casing 1 by pillars; the rotating disk 11 is located above the fixed disk 24, and several adaptive clamping mechanisms 10 for placing ampoules 9 are provided along the circumferential direction of the rotating disk 11 , the self-adaptive clamping mechanism 10 includes an ampoule hole 12 that runs through the turntable 11, three slider grooves 13 are uniformly arranged on the turntable 11 along the r...

Embodiment 2

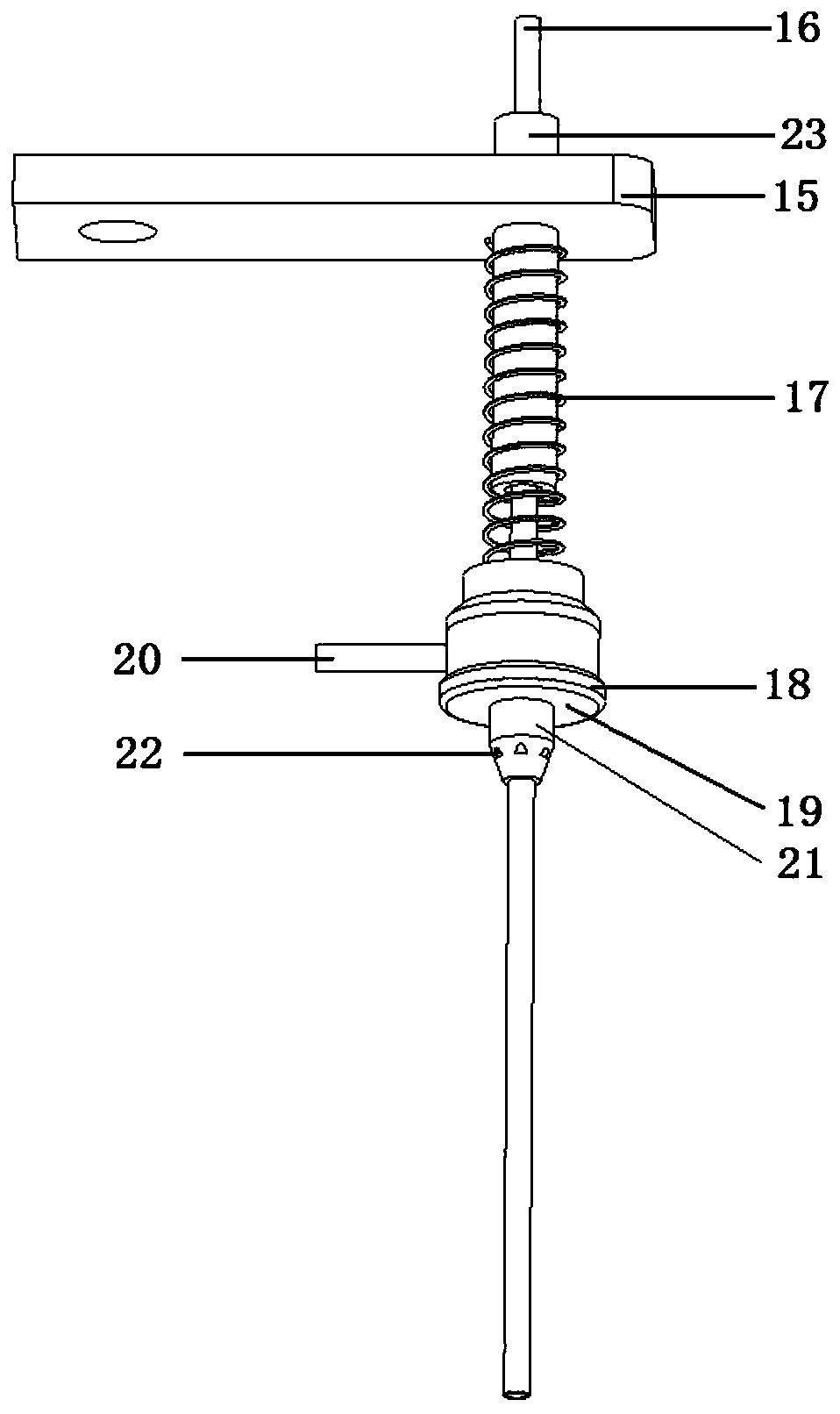

[0067] In order to be suitable for the filling of sensitive medicinal liquid, on the basis of embodiment 1, an inflatable tube 37 is set outside between the liquid feeding tube 36 and the pressure plate 18, and the inflatable tube 37 is connected to the inert gas storage tank through the air inlet tube 38. Connected, the lower end of the inflation tube extends out of the pressure plate 18 and is tapered, and a plurality of gas injection ports 39 are provided at the tapered end of the inflation tube. When filling, the liquid filling port can be filled with inert gas into the ampoule.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com