Sanding device for wood plastic plate

A wood-plastic board and sanding technology, which is applied in the direction of abrasive belt grinders, grinding/polishing equipment, grinding machines, etc., can solve the problem of inability to accurately ensure that it can be moved back to the second chute, shorten the service life of the sanding belt, and is difficult to restore to Initial position and other issues, to achieve the effect of simple mobile operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

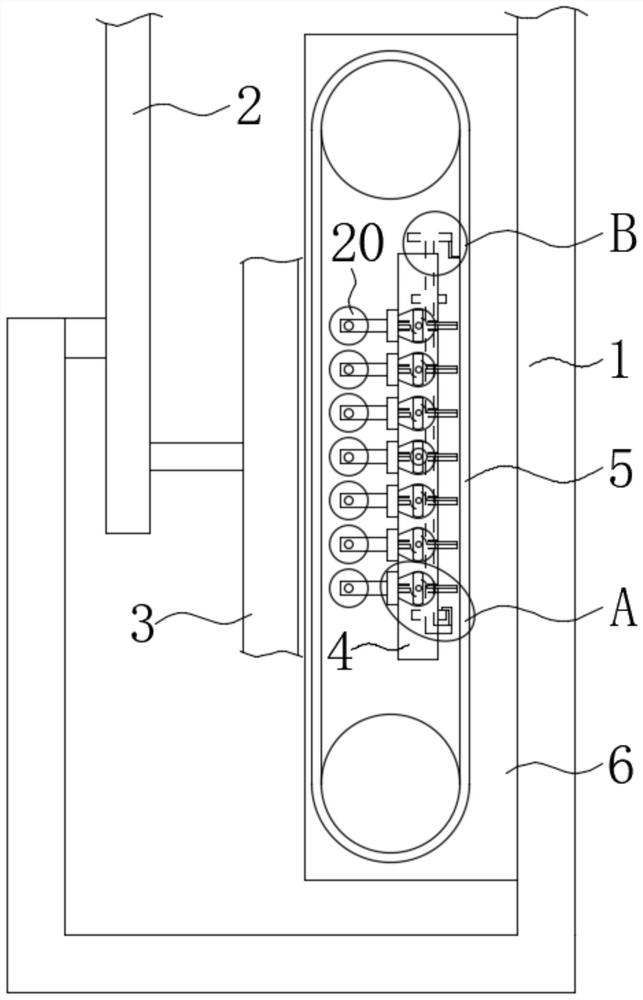

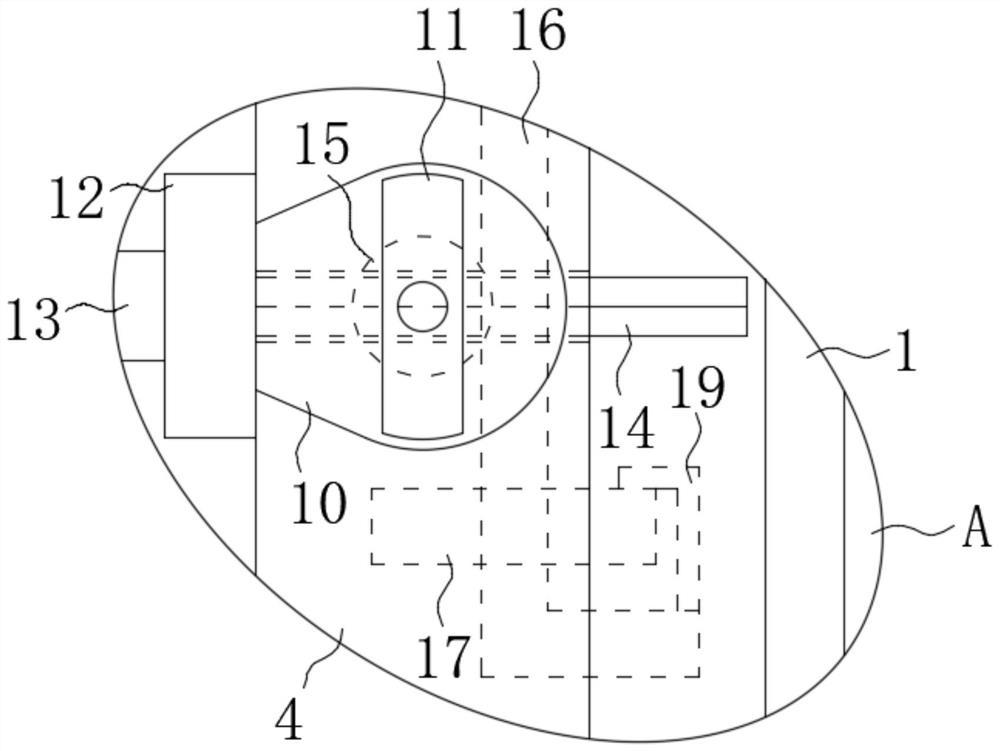

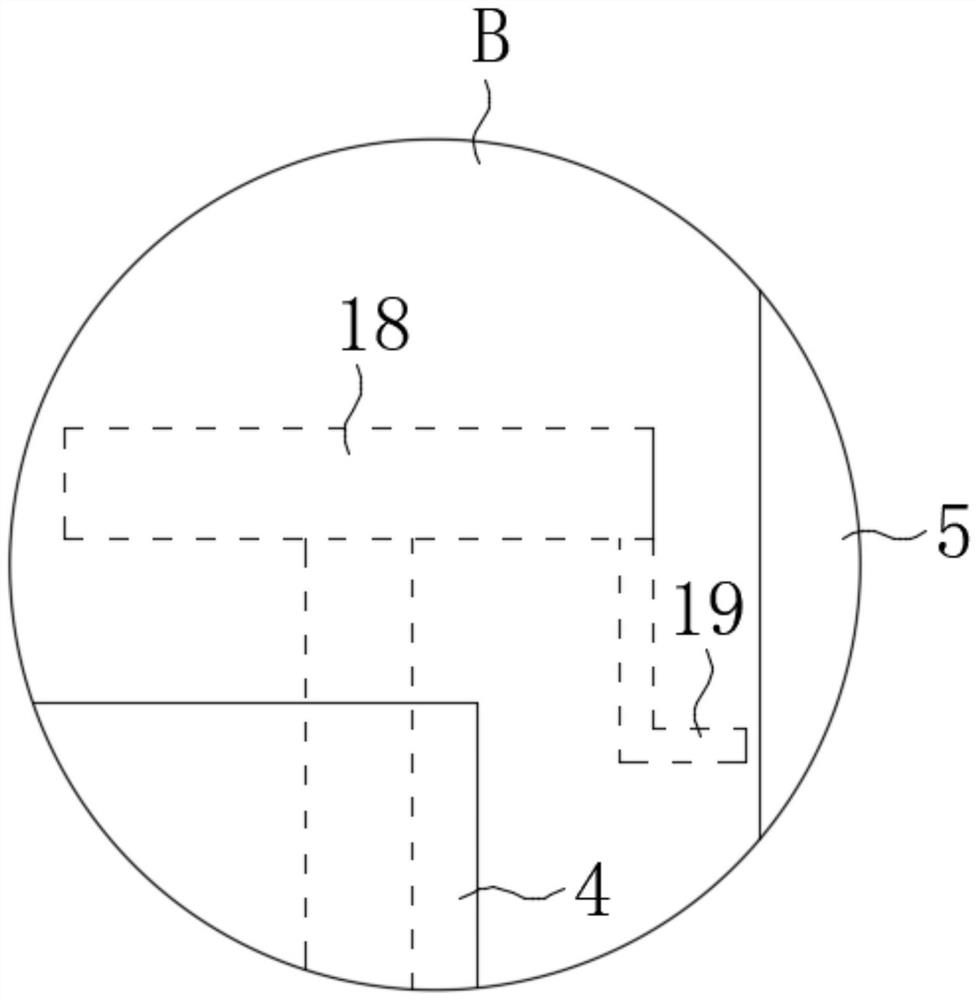

[0029] refer to Figure 1-5 , a wood-plastic board sanding device, including a frame body 1, a connecting plate 2, a wood-plastic board 3, a support beam 4, a sanding belt 5, a board body 6, a groove 7, a groove 2 8, a groove 3 9, support Be provided with a plurality of installation slots-10 on the beam 4, all in each installation slot-10, be installed with a magnetic bar 11 by rotating shaft rotation, on the sanding belt 5, be equipped with a plurality of matching with the magnetic bar 11 by supporting structure. Magnetic block one 12, each magnetic block one 12 is fixedly installed with a mounting rod 13, and a top roller 20 is installed in rotation between the corresponding two mounting rods 13;

[0030] The above points worth noting are as follows:

[0031] 1. The support structure is composed of a limit strut 14 and a square hole. A limit strut 14 is fixedly installed on the side of each magnetic block 12 away from the installation rod 13, and the end face shape of the l...

Embodiment 2

[0042] refer to Figure 4 , Figure 6, the difference between this embodiment and the first embodiment is that: a gear two 25 is installed on the rotating shaft through a one-way bearing two 24, and the self-locking direction of the one-way bearing two 24 is opposite to that of the one-way bearing one. There are chute 26, groove body one and groove body two, and groove body one communicates with chute 26 and installation groove two 21, and gear two 25 is located in the groove body, and groove body two communicates with chute 26, and chute 26 Two tooth bars 27 are slidingly installed in the interior, and a back-moving spring (not shown in the figure) is fixedly installed between the bottom wall of the chute 26 and the lower end of the tooth bar two 27, and the tooth bar two 27 is meshed with the gear two 25, A push block 28 is slidably installed in the tank body 2, and a through hole is opened in the middle part of the push block 28, a magnetic block 2 29 and a gear 3 30 are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com