A high-salt wastewater advanced oxidation method, industrial waste salt resource treatment method and equipment

A technology for advanced oxidation and high-salt wastewater, applied in the fields of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc. High reaction efficiency and the effect of improving the efficiency of advanced oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

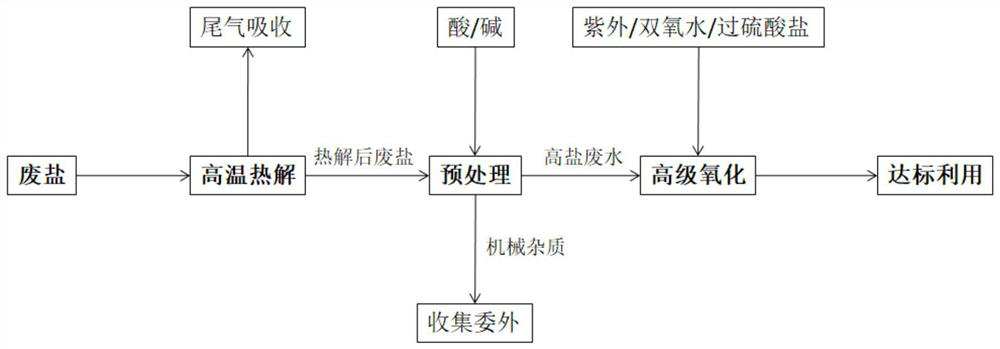

[0060] Such as figure 1 As shown, the waste salt of a certain chemical enterprise first uses a rotary heating furnace for high-temperature pyrolysis, and the waste salt after pyrolysis is dissolved in water to make high-salt wastewater, in which the mass fraction of control salt (sodium chloride) is 23%wt, After testing, compared with the waste water with the same mass fraction of the initial waste salt before pyrolysis, the TOC decreased from the initial 800.8mg / L to 33.1mg / L, and the TN decreased from the initial 40.3mg / L to 8.2mg / L , and then pass the wastewater through the pretreatment unit to remove impurities.

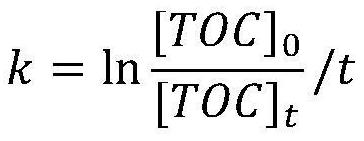

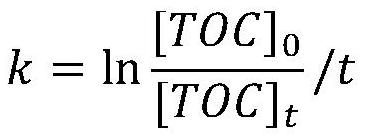

[0061] First, add hydrochloric acid to the reaction kettle to adjust the pH of the solution to 5.5. After the pH-adjusted wastewater is passed through a bag filter to remove particulate impurities, and after a small laboratory test, it is measured that the above-mentioned high-salt wastewater after pyrolysis is normal at 25°C. The first-order kinetic constant k ...

Embodiment 2

[0077] Waste salt from a chemical company first uses a multi-layer disc cracking furnace for high-temperature pyrolysis, and the pyrolyzed waste salt is dissolved in water to produce high-salt wastewater, in which the concentration of salt (sodium chloride) is controlled at 23% wt. Detect the TOC of waste salt and reduce to 29.9mg / L, TN by initial 35mg / L and reduce to 15mg / L (the TOC concentration of initial waste salt and the TN concentration are that waste salt is formulated as salt (chlorination) by initial 680mg / L Sodium) mass fraction is the corresponding concentration when 23%wt), then the high-salt wastewater is removed by the pretreatment unit.

[0078] First, through the pretreatment unit, the pH of the solution is adjusted to 5.5 by adding hydrochloric acid to the reactor. After the pH-adjusted wastewater is passed through a bag filter to remove particulate impurities, the above-mentioned pyrolyzed water is measured through a small laboratory test. The first-order ki...

Embodiment 3

[0103]Waste salt from a chemical company first uses a rotary heating furnace for high-temperature pyrolysis, and the pyrolyzed waste salt is dissolved in water to produce high-salt wastewater. The mass fraction of the control salt (sodium chloride) is 23%wt. After testing, the waste The TOC of salt reduces to 17.9mg / L by initial 450mg / L, TN reduces to 15mg / L by initial 40mg / L (TOC concentration and TN concentration of initial waste salt are that waste salt is formulated as salt (sodium chloride) The corresponding concentration when the mass fraction is 23%wt), is removed by the pretreatment unit.

[0104] First, add hydrochloric acid to the reaction kettle to adjust the pH of the solution to 5.5. After the pH-adjusted wastewater is passed through a bag filter to remove particulate impurities, and after a small laboratory test, it is measured that the above-mentioned high-salt wastewater after pyrolysis is normal at 25°C. The first-order kinetic constant k corresponding to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com