A treatment method and equipment for recycling industrial waste salt

A technology of industrial waste salt and treatment method, which is applied in the field of treatment method and equipment for industrial waste salt recycling, which can solve the problems of low efficiency of high-salt wastewater and decreased oxidation effect, and achieve the effect of improving the efficiency of advanced oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

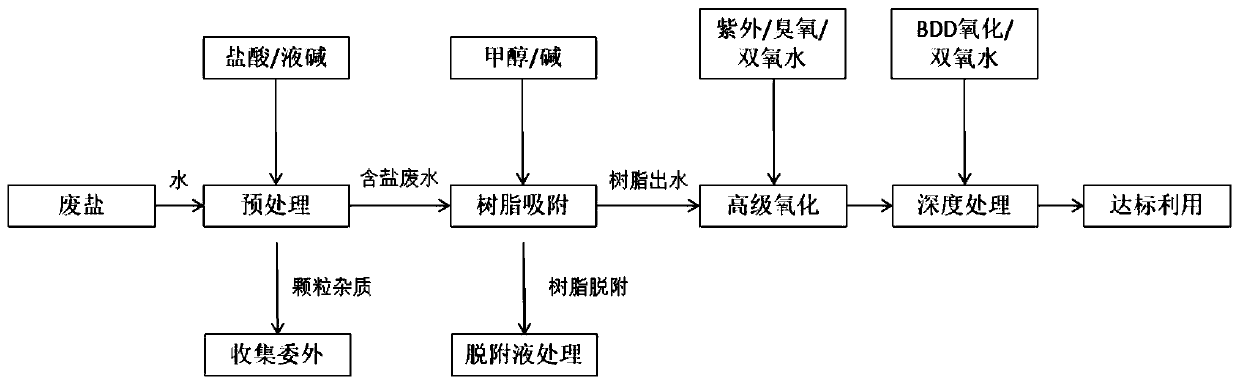

[0058] Such as figure 1 As shown, the waste salt of a chemical enterprise is firstly pretreated, and the waste salt is dissolved in water in an enameled reactor with agitation to produce high-salt wastewater. The control salt concentration is 23%wt, and TOC=800mg / L, TN=40 mg / L.

[0059] The method of the present invention is used for treatment. Firstly, the pH of the solution is adjusted to 2 by adding hydrochloric acid into the reaction kettle through the pretreatment unit, and the wastewater after the pH adjustment is passed through a bag filter to remove particulate impurities, and then resin adsorption is performed.

[0060] Using macroporous resin, after secondary adsorption by macroporous resin, TOC is reduced to 100mg / L, and TN is reduced to 31mg / L. After the macroporous resin is adsorbed and saturated, the resin is regenerated by alkali washing, and after repeated adsorption and desorption, the macroporous resin is deeply regenerated with methanol.

[0061] After th...

Embodiment 2

[0077] Waste salt from a chemical company, the control concentration is 23%wt, TOC=600mg / L, TN=40mg / L after testing.

[0078] The method of the present invention is used for treatment. Firstly, the pH of the solution is adjusted to 1.5 by adding hydrochloric acid into the reaction kettle through the pretreatment unit, and the wastewater after the pH adjustment is passed through a bag filter to remove particulate impurities, and then resin adsorption is performed.

[0079] Using macroporous resin, after secondary adsorption by macroporous resin, TOC is reduced to 50mg / L, and TN is reduced to 30mg / L. After the macroporous resin is adsorbed and saturated, the resin is regenerated by alkali washing, and after repeated adsorption and desorption, the macroporous resin is deeply regenerated with methanol.

[0080] After that, advanced oxidation unit treatment is carried out, in which the advanced oxidation unit is carried out in three ways: ozone, hydrogen peroxide and ultraviolet li...

Embodiment 3

[0096] The waste salt of a chemical company has a controlled concentration of 23%wt. After testing, TOC=400mg / L, TN=38mg / L.

[0097] Adopt the method of the present invention to process, at first through the pretreatment unit, adjust the solution pH=1.5 by adding hydrochloric acid in the reaction kettle, after the wastewater after adjusting pH is removed particle impurity through bag filter, carry out resin adsorption, adopt large-scale Porous resin, after secondary adsorption of macroporous resin, TOC is reduced to 80mg / L, and TN is reduced to 28mg / L. After the macroporous resin is adsorbed and saturated, the resin is regenerated by alkali washing, and after repeated adsorption and desorption, the macroporous resin is deeply regenerated with methanol.

[0098] After that, advanced oxidation unit treatment is carried out, in which the advanced oxidation unit is carried out in three ways: ozone, hydrogen peroxide and ultraviolet light at the same time, and the pH of the wastewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com