High-salinity wastewater advanced oxidation method,industrial waste salt resourceful treatment method, and equipment

A technology for advanced oxidation and high-salt wastewater, which is applied in the fields of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., and can solve the problems of inability to practically solve organic pollutants, high treatment costs, and insufficient incineration, etc. Achieve the effect of improving advanced oxidation efficiency and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

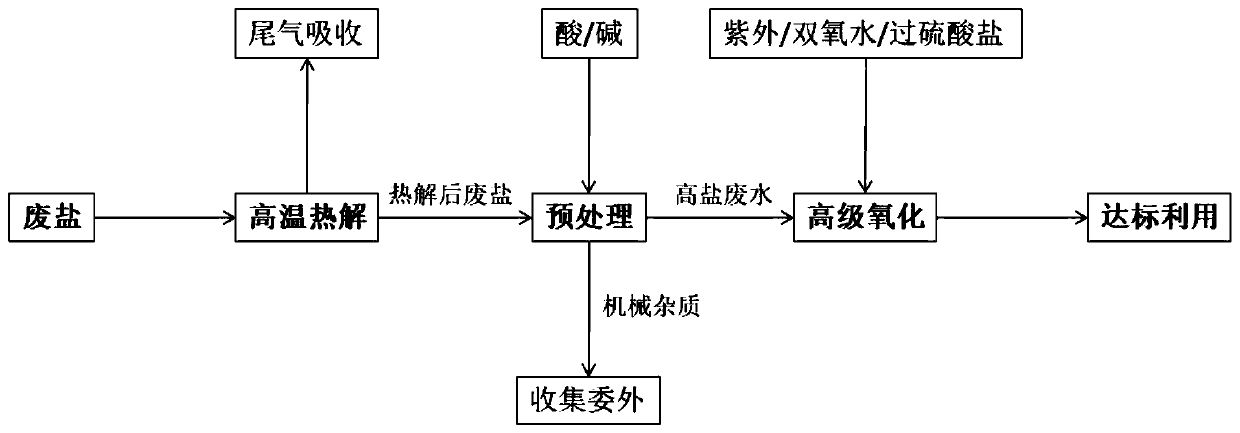

[0060] Such as figure 1 As shown, the waste salt of a certain chemical enterprise first uses a rotary heating furnace for high-temperature pyrolysis, and the waste salt after pyrolysis is dissolved in water to make high-salt wastewater, in which the mass fraction of control salt (sodium chloride) is 23%wt, After testing, compared with the waste water with the same mass fraction of the initial waste salt before pyrolysis, the TOC decreased from the initial 800.8mg / L to 33.1mg / L, and the TN decreased from the initial 40.3mg / L to 8.2mg / L , and then pass the wastewater through the pretreatment unit to remove impurities.

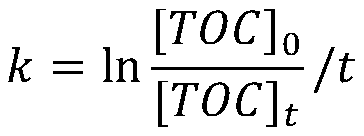

[0061] First, add hydrochloric acid to the reaction kettle to adjust the pH of the solution to 5.5. After the pH-adjusted wastewater is passed through a bag filter to remove particulate impurities, and after a small laboratory test, it is measured that the above-mentioned high-salt wastewater after pyrolysis is normal at 25°C. The first-order kinetic constant k ...

Embodiment 2

[0077] Waste salt from a chemical company first uses a multi-layer disc cracking furnace for high-temperature pyrolysis, and the pyrolyzed waste salt is dissolved in water to produce high-salt wastewater, in which the concentration of salt (sodium chloride) is controlled at 23% wt. Detect the TOC of waste salt and reduce to 29.9mg / L, TN by initial 35mg / L and reduce to 15mg / L (the TOC concentration of initial waste salt and the TN concentration are that waste salt is formulated as salt (chlorination) by initial 680mg / L Sodium) mass fraction is the corresponding concentration when 23%wt), then the high-salt wastewater is removed by the pretreatment unit.

[0078] First, through the pretreatment unit, the pH of the solution is adjusted to 5.5 by adding hydrochloric acid to the reactor. After the pH-adjusted wastewater is passed through a bag filter to remove particulate impurities, the above-mentioned pyrolyzed water is measured through a small laboratory test. The first-order ki...

Embodiment 3

[0103]Waste salt from a chemical company first uses a rotary heating furnace for high-temperature pyrolysis, and the pyrolyzed waste salt is dissolved in water to produce high-salt wastewater. The mass fraction of the control salt (sodium chloride) is 23%wt. After testing, the waste The TOC of salt reduces to 17.9mg / L by initial 450mg / L, TN reduces to 15mg / L by initial 40mg / L (TOC concentration and TN concentration of initial waste salt are that waste salt is formulated as salt (sodium chloride) The corresponding concentration when the mass fraction is 23%wt), is removed by the pretreatment unit.

[0104] First, add hydrochloric acid to the reaction kettle to adjust the pH of the solution to 5.5. After the pH-adjusted wastewater is passed through a bag filter to remove particulate impurities, and after a small laboratory test, it is measured that the above-mentioned high-salt wastewater after pyrolysis is normal at 25°C. The first-order kinetic constant k corresponding to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com