Base oil and lubricating oil

A technology of base oils and monoalcohols, applied in the field of base oils and lubricating oils containing ester compounds, can solve the problem of high pour point, low base oil extreme pressure, and inability to meet low viscosity, high flash point, low pour point and high pole oil at the same time Problems such as pressure characteristics, to achieve the effect of low viscosity, high flash point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053]

[0054]The preparation method of the base oil of the present invention comprises an esterification step. The esterification step is to carry out esterification reaction between the fatty acid component and the unit alcohol component. The detailed description (or reaction conditions) of the fatty acid component, the unit alcohol component and the esterification reaction is the same as the description (or reaction condition) of the fatty acid component, the unit alcohol component and the esterification reaction in the previous .

[0055] Preferably, the preparation method of the present invention also includes a purification step after the esterification reaction. The purification step is to remove water, catalyst and impurities in the product obtained after the esterification reaction.

Embodiment 1

[0058] The base oils of Example 1 and Comparative Examples 1-6 were prepared by the following esterification steps and purification steps respectively.

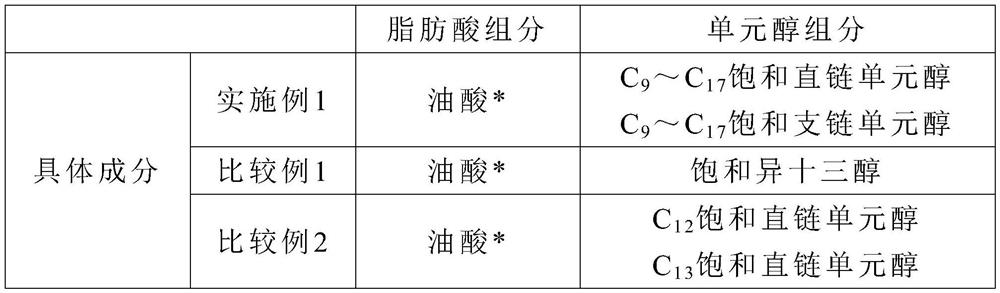

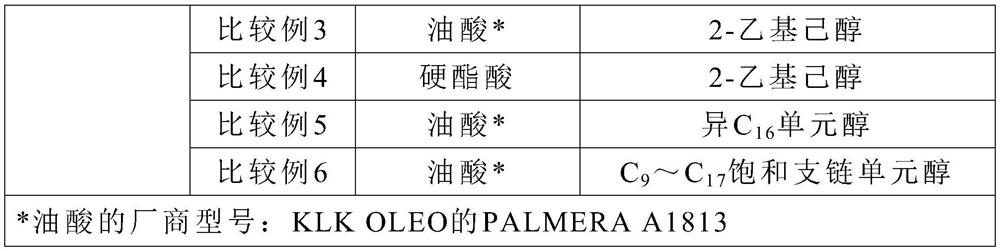

[0059] Step (1)-esterification step: In the presence of stannous oxalate (catalyst), the fatty acid component and the unit alcohol component are subjected to esterification reaction (reaction temperature is 200-230°C) until the hydroxyl value is below 1mgKOH / g Afterwards, an unpurified base oil is obtained. The specific components of the unit alcohol component and the fatty acid component are arranged in the following table 1, and the ratio of the unit alcohol component and the fatty acid component is based on the hydroxyl value of the unpurified base oil to be obtained Adjust, and the concentration of the stannous oxalate in the reaction is 250-500ppm.

[0060] Table 1

[0061]

[0062]

[0063] More specifically for the unit alcohol component of Example 1 in Table 1 above, the unit alcohol component is composed of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com