A kind of imitation rabbit plush fiber fabric

A technology of rabbit plush and fiber, applied in the field of textile fabrics, to achieve the effect of warm, delicate and smooth hand feeling, good texture and rich fluff texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

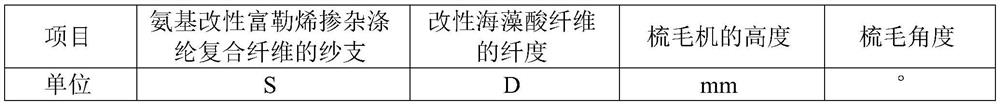

preparation example Construction

[0019] Further, the preparation method of the amino-modified fullerene-doped polyester composite fiber comprises the following steps:

[0020] Step S1. Mix the amino-modified fullerene and polyester slices evenly to obtain a mixture, and then add the mixture to a twin-screw extruder to extrude and pelletize to obtain amino-modified fullerene-polyester masterbatch ;

[0021] Step S2, melt-spinning the amino-modified fullerene-polyester masterbatch prepared in step S1 to prepare the amino-modified fullerene-doped polyester composite fiber.

[0022] Further, the extrusion granulation temperature in step S1 is 190-230°C.

[0023] Further, the mass ratio of the amino-modified fullerene to the polyester chips in step S1 is 1:(15-25).

[0024] Preferably, the diameter of the spinneret hole of the melt spinning spinneret is 0.05-0.15 mm.

[0025] Further, the modified alginic acid fiber is made by spraying an aqueous solution of 1,3-dimethylimidazole chloride with a mass fraction o...

Embodiment 1

[0030] This example provides a kind of imitation rabbit plush fiber fabric, including velvet texture and bottom thread texture, which is formed by needle warp knitting on a double-needle bed warp knitting machine by velvet silk and bottom thread; The mass percentage is 30%, and the velvet forming the velvet structure is 75D-300D polyester full-dull or semi-dull flat, and the bottom thread forming the velvet structure is 75D FDY;

[0031] The preparation method of imitation rabbit plush fiber fabric comprises the steps:

[0032] (1) Weaving: Select 75D-300D full-dull or super-dull flat polyester yarn as the pile yarn, 75D FDY as the bottom yarn, and knit it into a fabric blank according to the set needle process on the double-needle bed warp knitting machine ;

[0033] (2) cutting width: the fabric blank woven in the step (1) is carried out cutting width processing on the width cutting machine;

[0034] (3) pre-treatment: carry out blank carding, scalding and pre-setting proc...

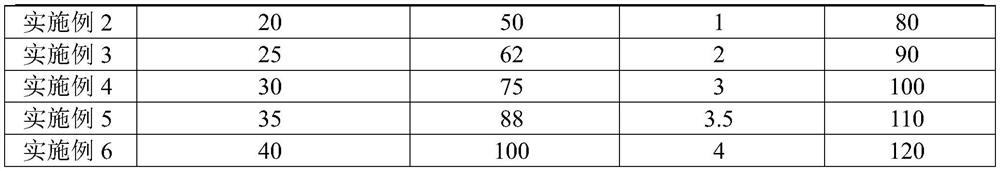

Embodiment 2

[0038] This example provides a kind of imitation rabbit plush fiber fabric, including velvet texture and bottom thread texture, which is formed by needle warp knitting on a double-needle bed warp knitting machine by velvet silk and bottom thread; The mass percentage is 30%, and the fleece forming the fleece structure is amino-modified fullerene-doped polyester composite fiber, and the bottom filament forming the bottom filament structure is modified alginic acid fiber.

[0039] The preparation method of described amino-modified fullerene-doped polyester composite fiber, comprises the steps:

[0040] Step S1. Mix the amino-modified fullerene and polyester slices evenly to obtain a mixture, and then add the mixture to a twin-screw extruder to extrude and pelletize to obtain amino-modified fullerene-polyester masterbatch ;

[0041] Step S2, melt-spinning the amino-modified fullerene-polyester masterbatch prepared in step S1 to prepare the amino-modified fullerene-doped polyester...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com