Safety guardrail for highway construction

A technology for safety guardrails and highways, which is applied to road safety devices, roads, roads, etc., can solve the problems of poor protection effect, low protection effectiveness, and inability to use continuous protection devices, so as to reduce material and labor costs, and achieve protection effectiveness. The effect of improving and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

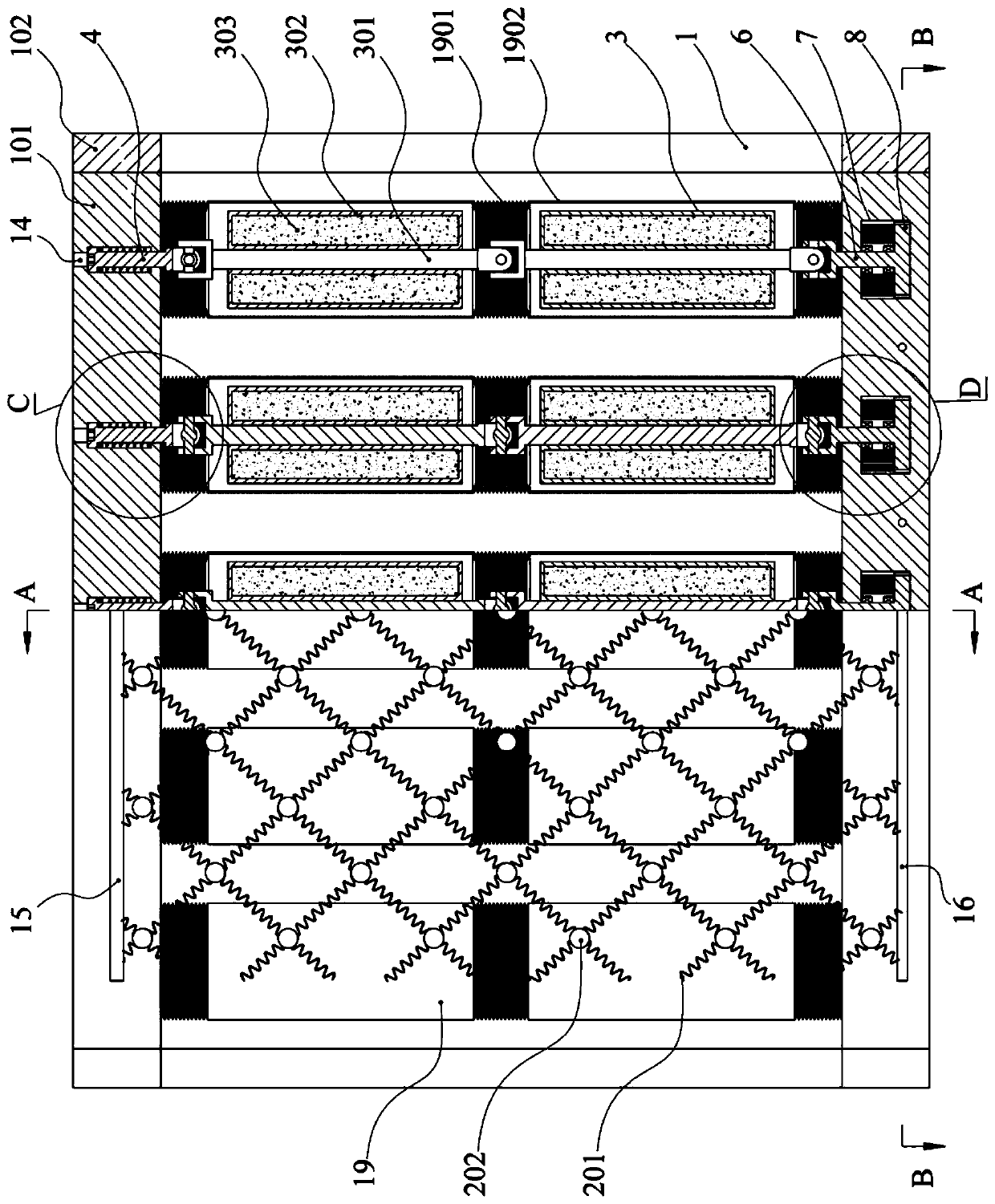

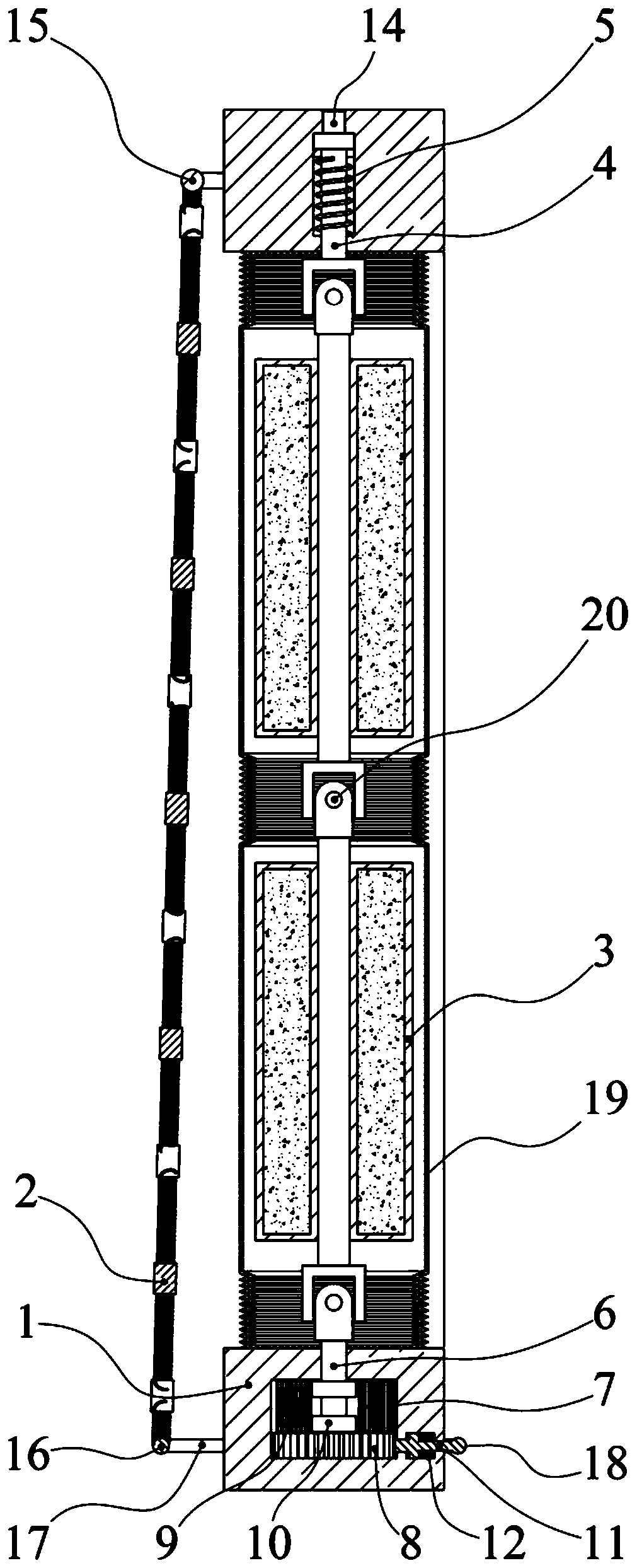

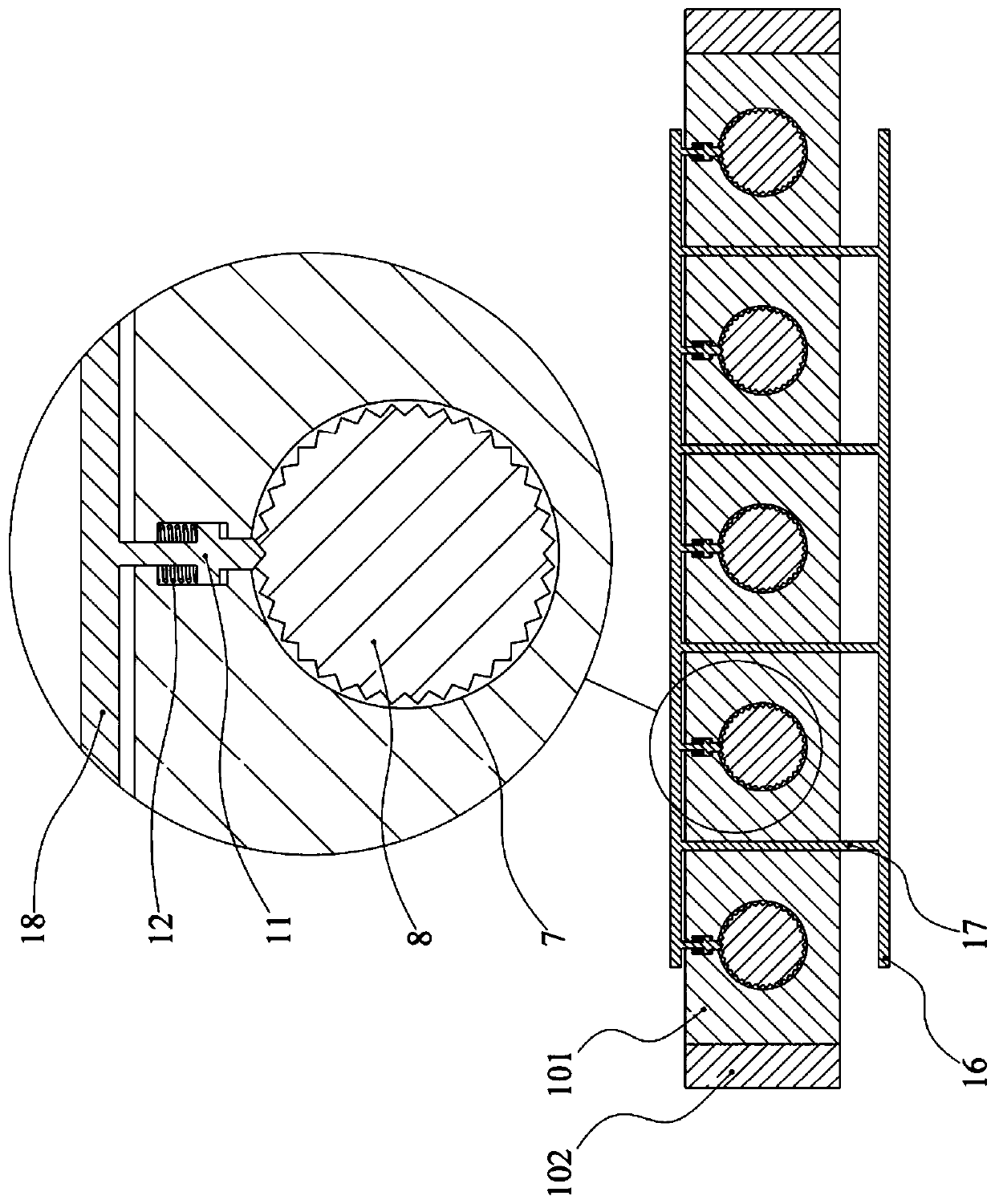

[0015] Depend on Figure 1 to Figure 7 Provided, the present invention includes a rectangular frame 1 and a steel wire mesh 2 placed on the front side of the frame 1. There are a plurality of buffer assemblies distributed horizontally on the frame 1. The buffer assemblies are formed by two rollers 3 coaxially arranged up and down. The cross shaft is composed of 20 universal hinges; the frame 1 has a plurality of vertically arranged guide rods 4 corresponding to the buffer components one by one, and the upper end of the guide rod 4 is vertically slidably connected with the frame 1 and passed through the first The spring 5 is connected, and the guide rod 4 slides upward under the elastic force of the first spring 5, and the lower end of the guide rod 4 and the upper end of the buffer assembly are hinged universally through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com