Steel bar correction device for prefabricated column of prefabricated building

A correction device and prefabricated column technology, which is applied in the mechanical field, can solve the problems of column steel bar offset and unsatisfactory hoisting, and achieve the effect of fast detection and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

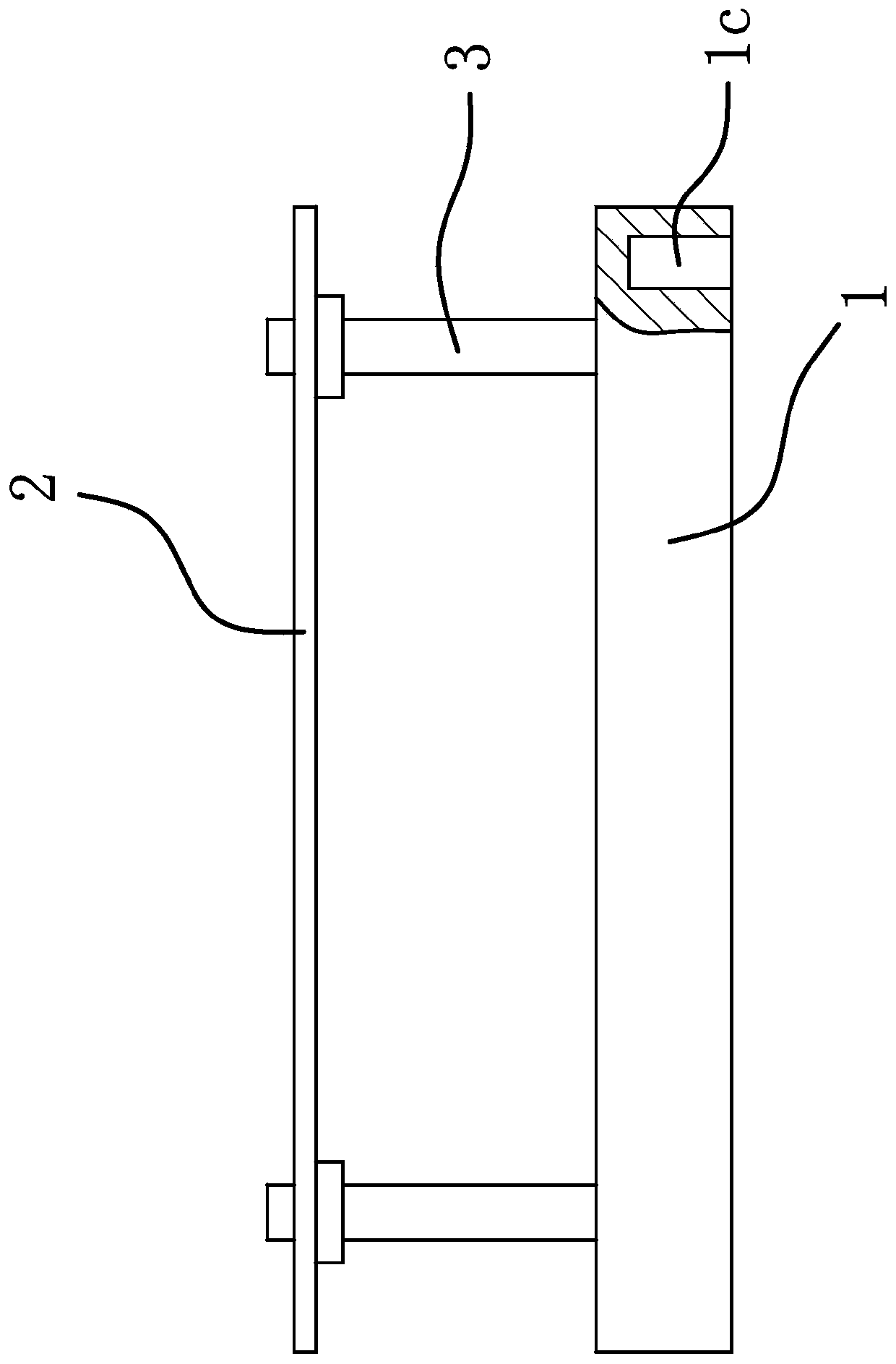

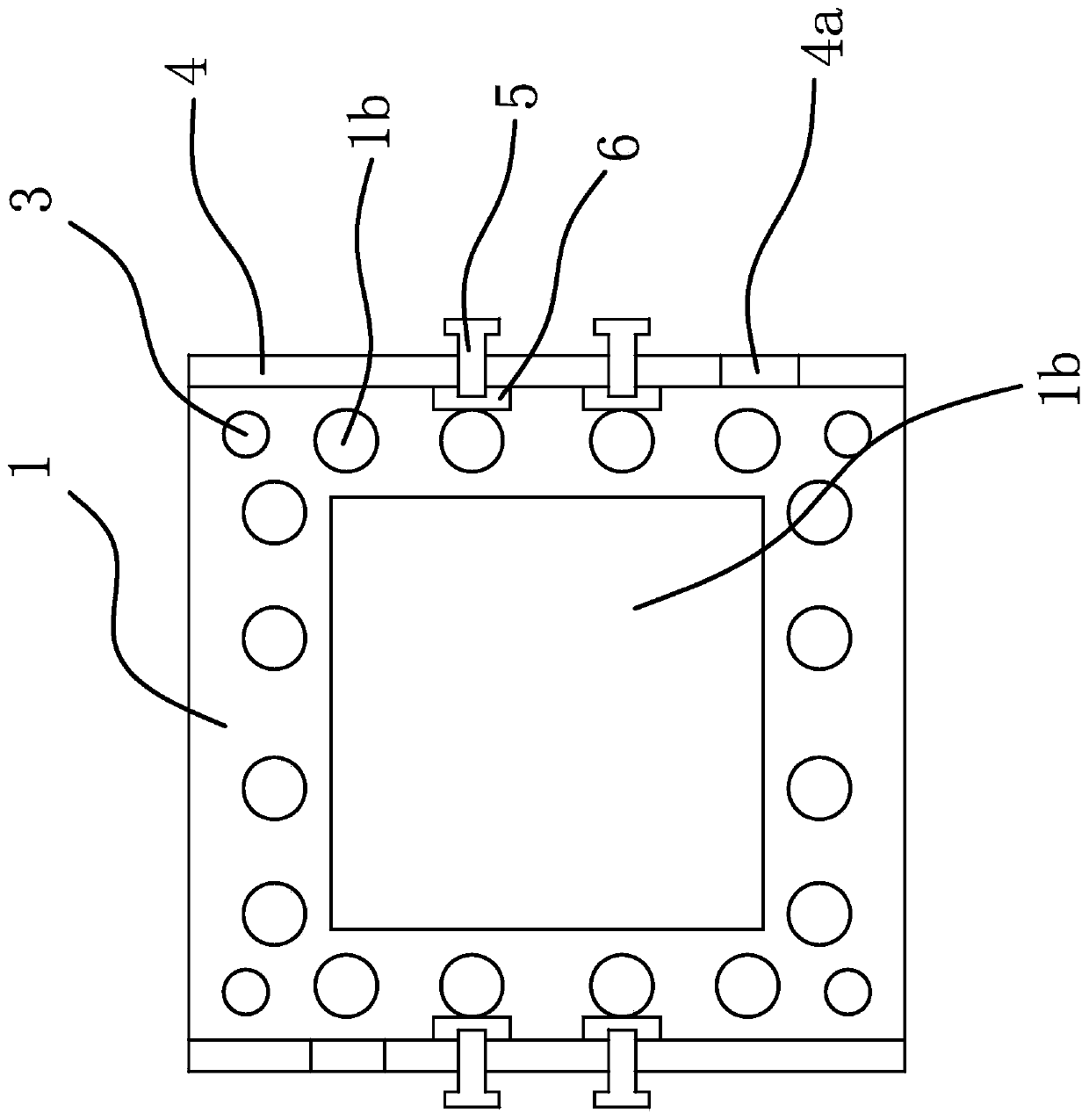

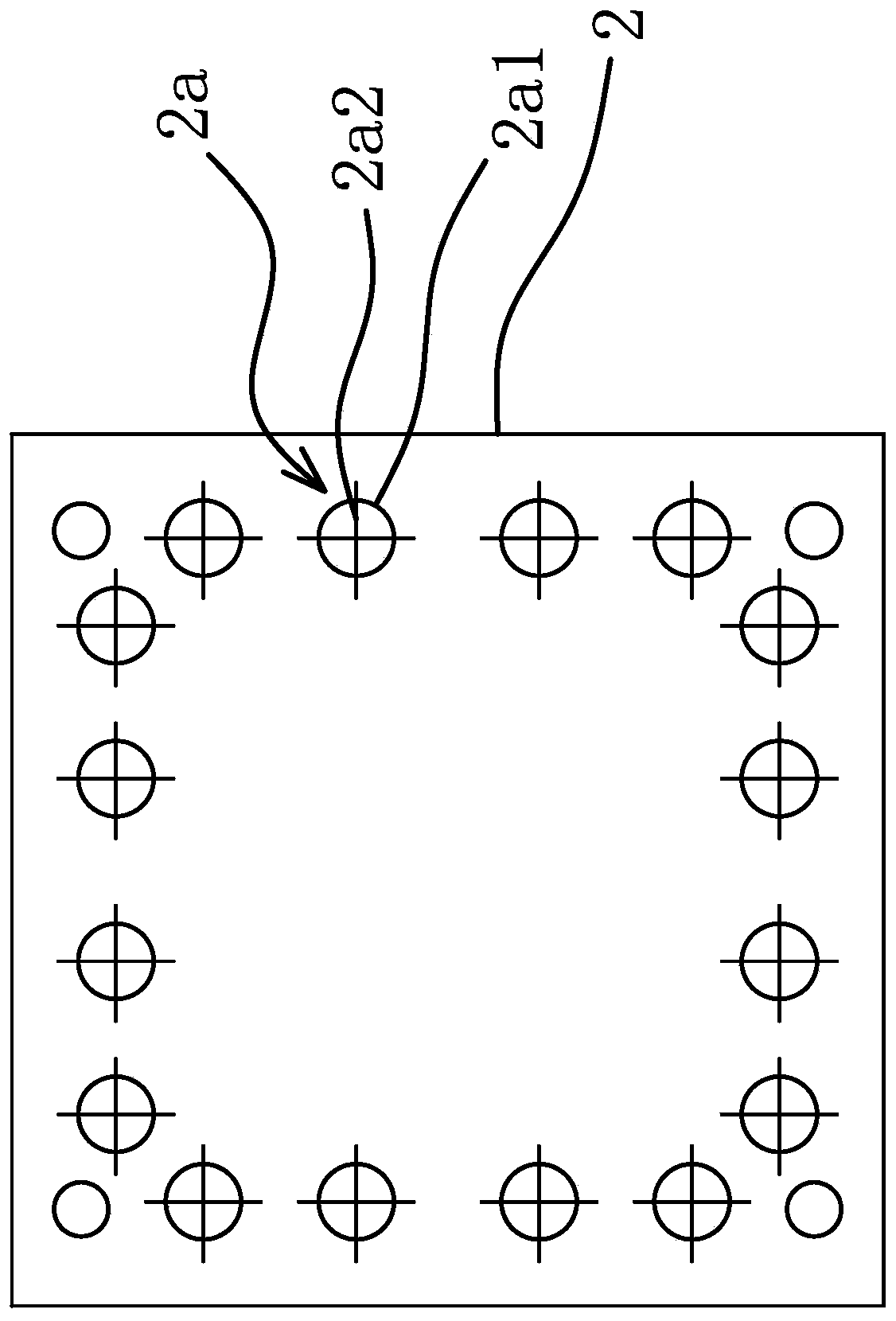

[0037] Such as figure 1 and figure 2 and image 3 As shown, the steel bar correction device of the prefabricated column of the prefabricated building includes a bottom plate 1, a correction plate 2 and a connecting rod 3, the lower end of the connecting rod 3 is connected to the bottom plate 1, and the upper end of the connecting rod 3 is connected to the correction plate 2, and the bottom plate 1 has a number of through calibration holes 1a close to its edge, the calibration plate 2 is a transparent material and has a number of calibration marks 2a on the calibration plate 2, and the calibration marks 2a are set in one-to-one correspondence with the calibration holes 1a.

[0038] The bottom plate 1 has a through hole 1b in the center, and the calibration holes 1c are distributed around the through hole 1b.

[0039] The edge of the bottom plate 1 is fixedly connected with a strip-shaped fixing strip 4, and the fixing strip 4 has a positioning structure. When the steel bar o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com