Built-in humidifier for pharmaceutical production equipment

A technology for pharmaceutical production and humidifiers, which is applied in mechanical equipment, air humidification systems, lighting and heating equipment, etc. It can solve problems such as increasing hidden dangers in use, shortening the service life of humidifiers, and being unable to respond to emergencies in time to achieve safe operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

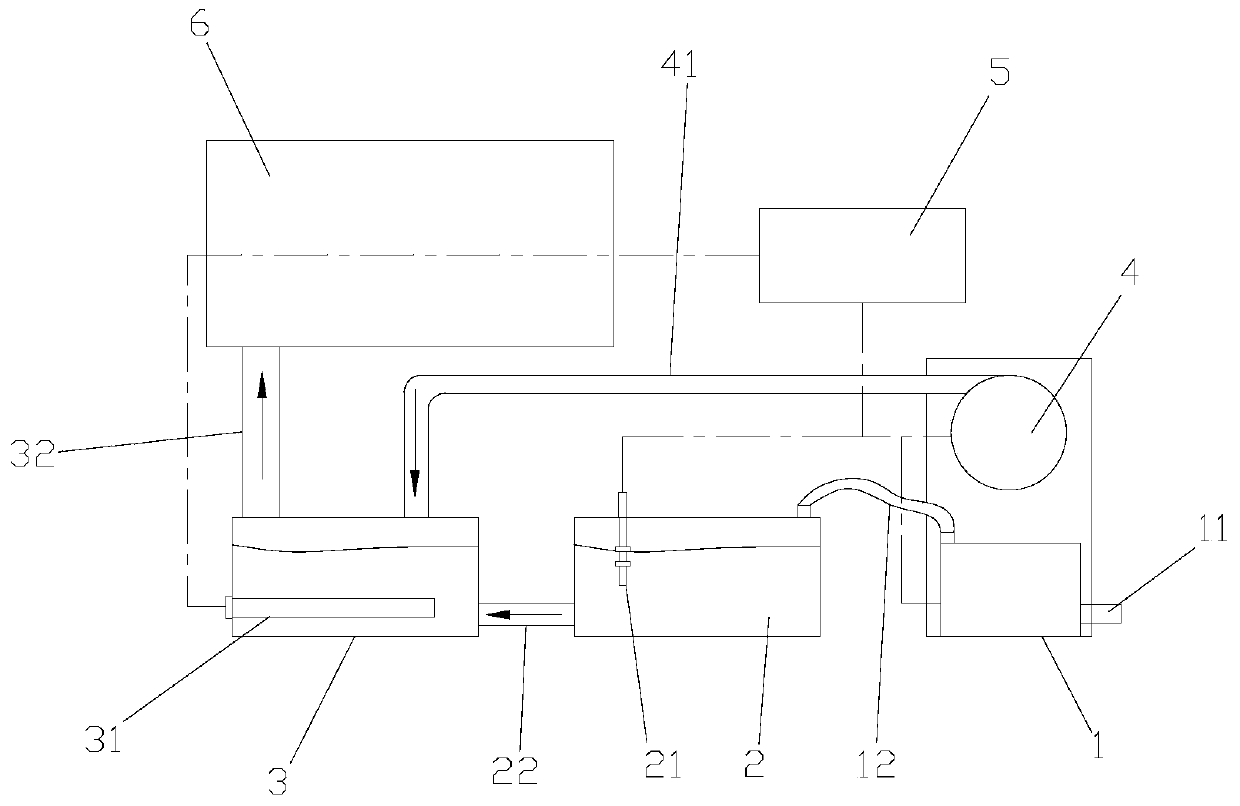

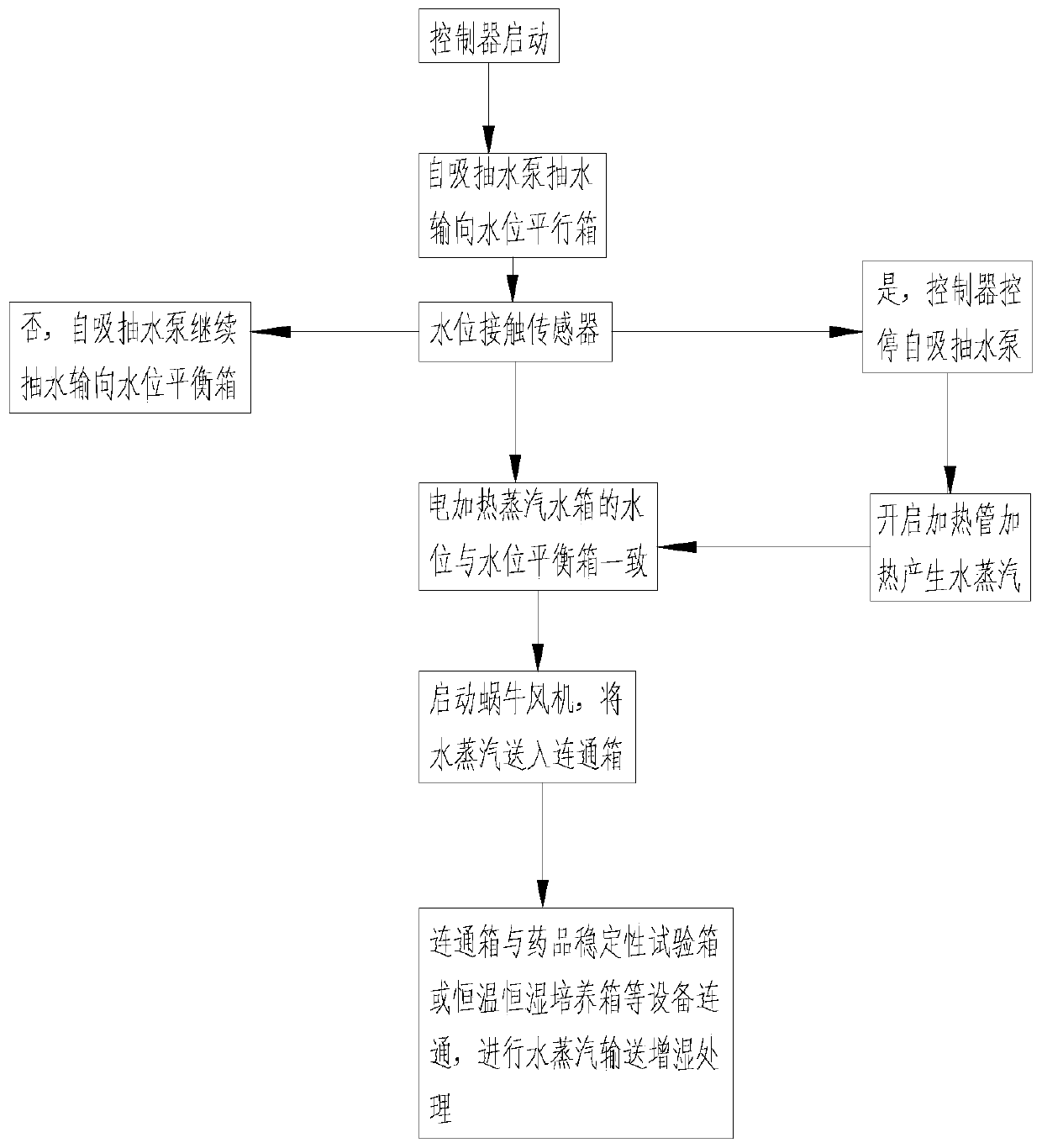

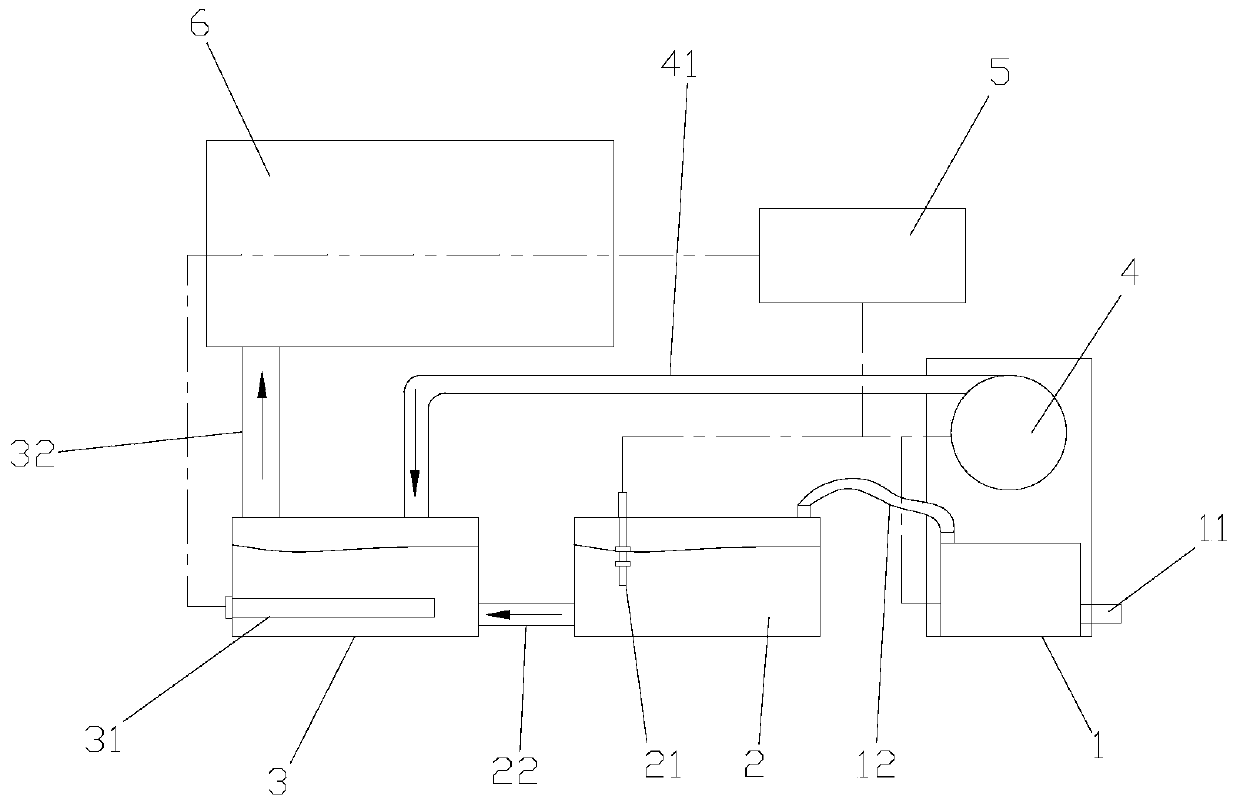

[0022] A built-in humidifier for pharmaceutical production equipment such as figure 1 As shown, the self-priming water pump 1 connected to the external water storage tank, the water level balance tank 2 fixed and communicated with the self-priming water pump 1, and the electric heating steam fixed and communicated with the water level balance tank 2 Water tank 3, the snail blower 4 fixed and communicated with the electric heating steam water tank 3 is used to electrically connect and control the water level height in the water level balance box 2, control the heating temperature of the electric heating steam water tank 3, and the control of the rotation air intake of the snail blower 4 device 5, and a communication box 6 connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com