Vernier type high-precision welding fixture and measuring tool with seat

A welding fixture, high-precision technology, applied in the direction of auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problem that the welding plate or welding fixture or marking line cannot meet the requirements of frequent changes in technical status, and achieve easy use , the effect of quantitative measures of economic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

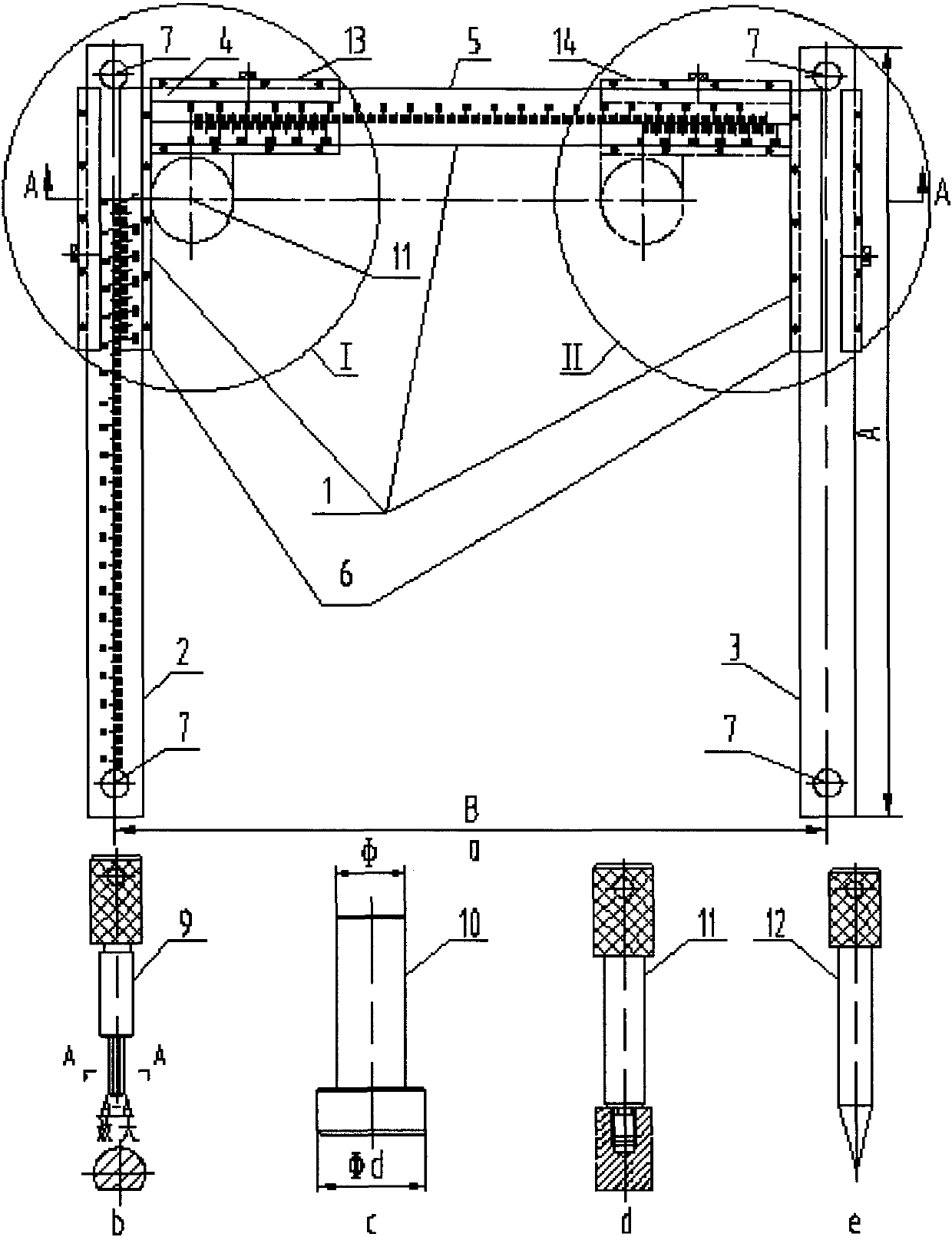

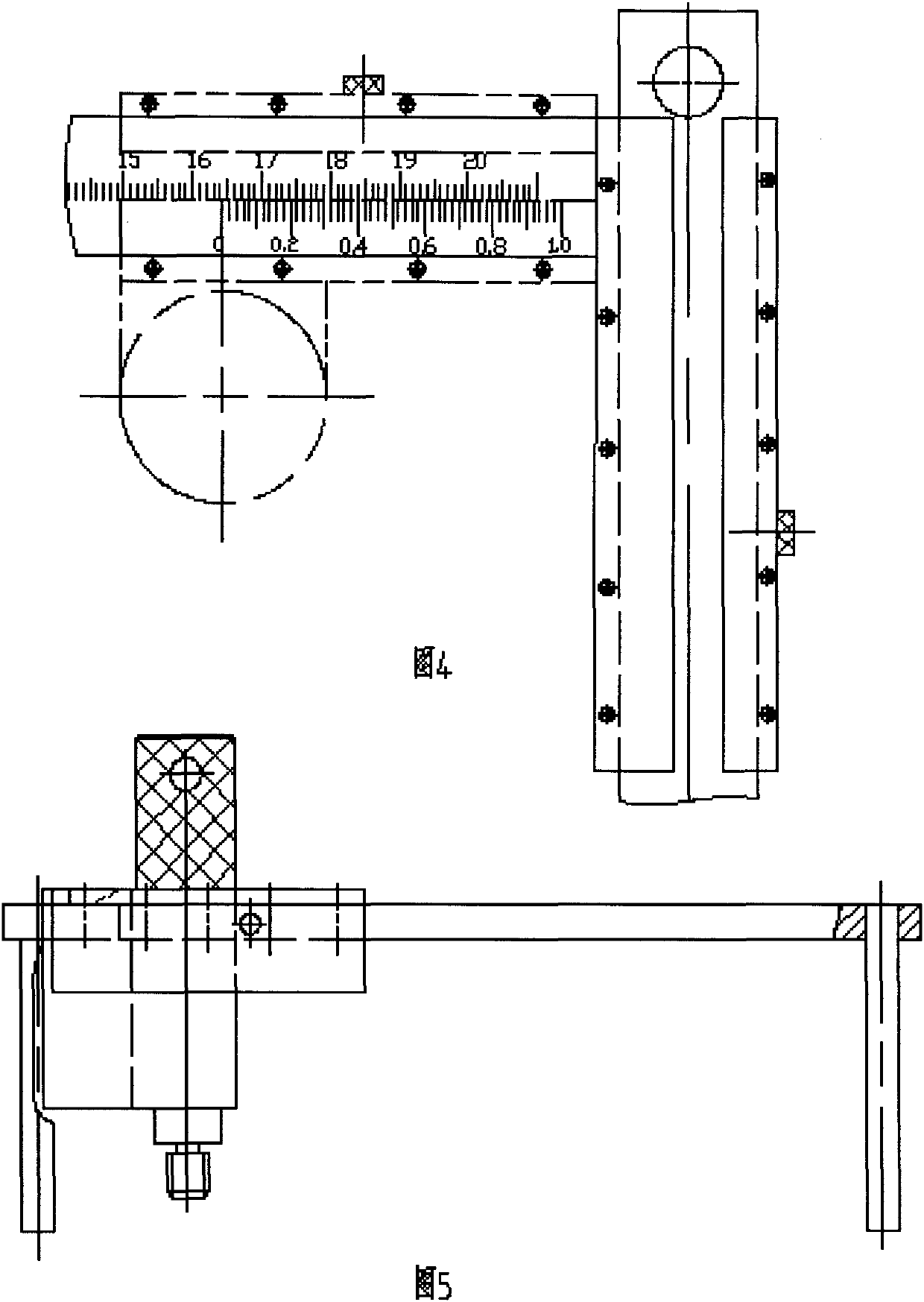

[0056] Such as Figure 12 As shown, on a certain welding plane, there are 25 auxiliary seats evenly distributed on the indexing circle based on the center of the hole ФD and there are position requirements. The implementation steps are as follows:

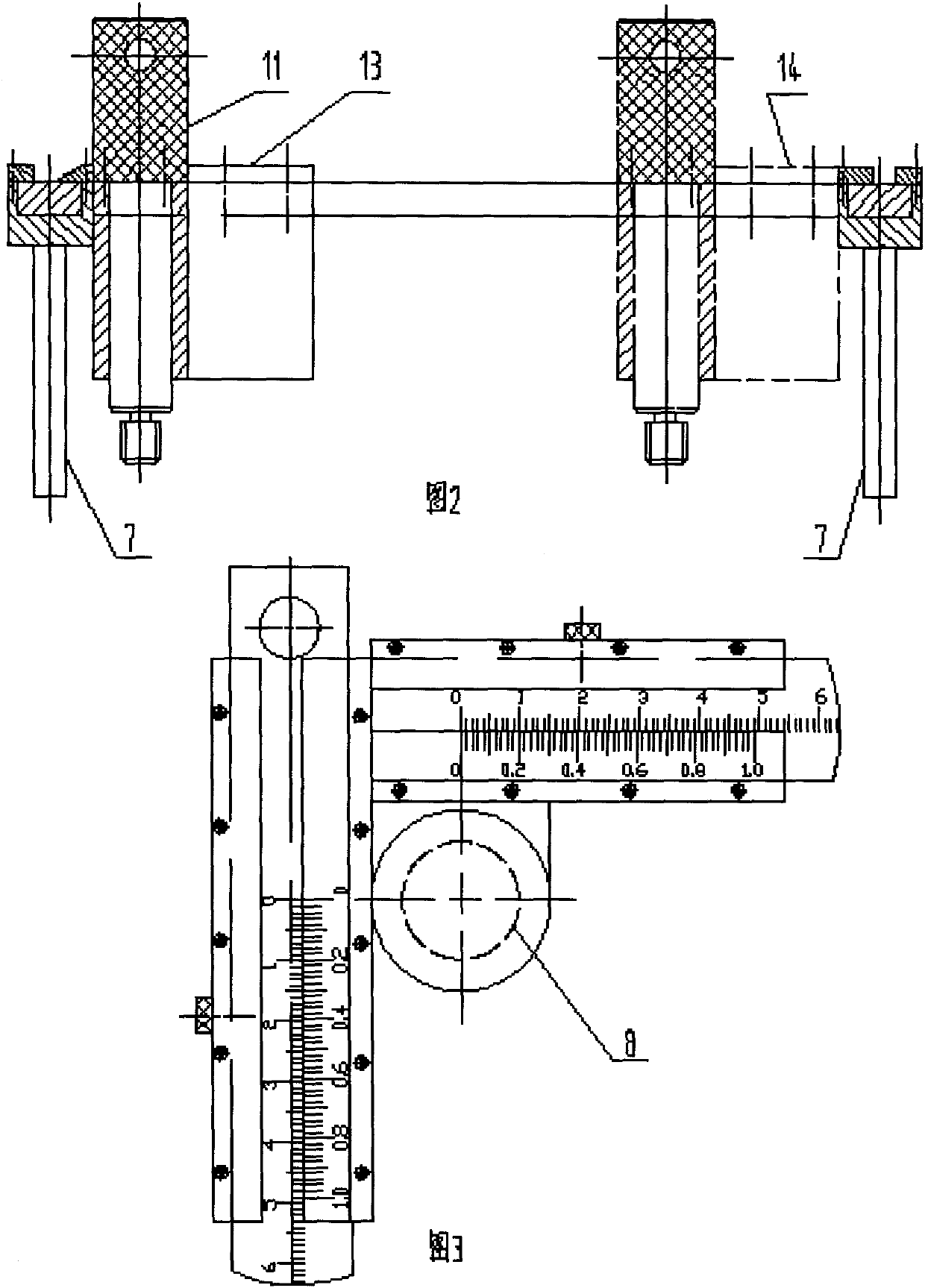

[0057] (1) Adjust the position of the fixture so that the overall beam ruler 1 is parallel to the horizontal centerline of the reference hole ФD, and the longitudinal beam ruler 2 and longitudinal beam 3 are parallel to the vertical centerline of the reference hole ФD at the same time. When the location hole 8 is at the starting position, the center position of 13 is the coordinate origin, and its horizontal centerline is the horizontal axis, and the vertical centerline is the vertical axis, and a plane Cartesian coordinate system is established, so that the location pin 11, the location pin 9, the location mandrel 10 or datum positioning pin 12 can reach any point in the plane Cartesian coordinate system of fixture itself.

[00...

Embodiment 2

[0066] Such as Figure 13 As shown, on a certain welding plane, there are 36 attachments that are evenly distributed. They not only have positional requirements relative to reference plane A and reference plane B, but also have positional requirements between two adjacent attachments. The implementation steps are as follows:

[0067] (1) Take the intersection of datum plane A and datum plane B as the coordinate origin, the horizontal direction as the horizontal axis, and the vertical direction as the vertical axis to establish a plane Cartesian coordinate system.

[0068] (2) Convert the positional dimensions between two pairs of 36 attached seats into plane Cartesian coordinates and record them.

[0069] (3) After passing the reference positioning pin 12 through the positioning hole 8 on the vernier ruler 4 from top to bottom (the matching relationship is H7 / g6), by sliding the vernier ruler 4 and the overall beam ruler 1 at the same time, the position of the reference posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com