Method and system for controlling casting blank of slab casting machine

A slab continuous casting and slab technology, which is applied in the field of slab casting machine slab control, can solve problems such as slab retention, production, operation, equipment, quality, and cost impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

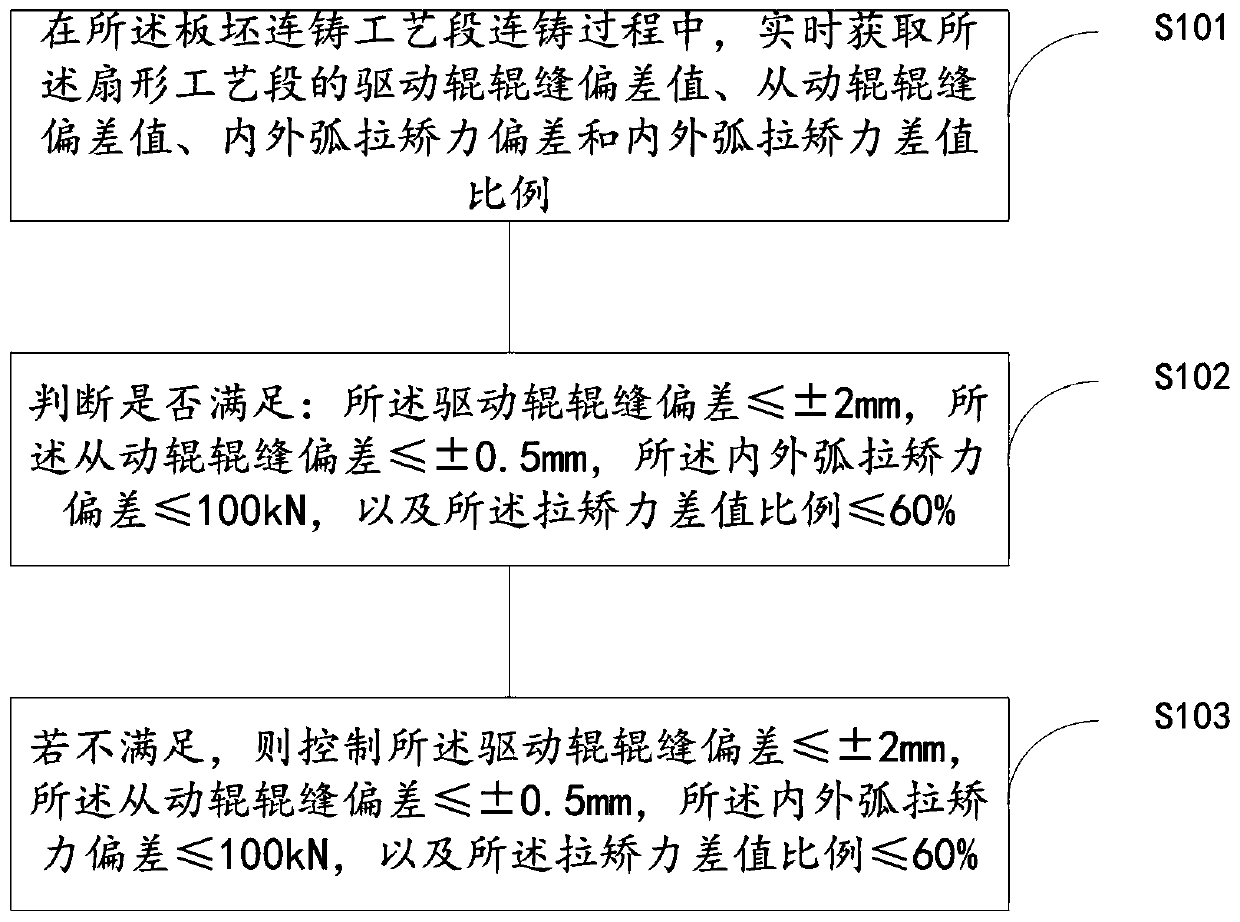

[0040] This embodiment provides a slab caster control method for the slab continuous casting process section, the slab continuous casting process section includes a fan-shaped process section, and the inner and outer arcs of the fan-shaped process section exist at the same time tension leveling machine, see figure 1 , the method includes:

[0041] S101. During the continuous casting process of the slab continuous casting process section, obtain in real time the roll gap deviation value of the driving roll, the roll gap deviation value of the driven roll, the deviation of the inner and outer arc tension correction force, and the difference between the inner and outer arc tension correction force of the sector-shaped process section value ratio;

[0042] S102. Judging whether it is satisfied: the gap deviation of the driving roller is ≤±2mm, the gap deviation of the driven roller is ≤±0.5mm, the deviation of the inner and outer arc tension correction force is ≤100kN, and the ra...

Embodiment approach

[0061] It should be noted that, even if the control is carried out according to the method of this embodiment, if the monitoring fault exceeds the control fault, etc., it may still lead to the occurrence of the stagnation phenomenon. Therefore, it is necessary to carry out early warning of the stagnation phenomenon. The method also includes:

[0062] Real-time monitoring of the deviation between the length measurement of the tension leveler and the length measurement of the measuring wheel;

[0063] If the deviation between the measured length of the tension leveling machine and the measured length of the measuring wheel is ≥0.5m or the running length of the slab measured by the slab measuring wheel is 0 within 30s, it is judged that the slab caster is stuck.

[0064] When slab stagnation occurs, the following measures can be taken for emergency treatment to prevent the slab from lying: (1) after the slab is stagnant, cancel the equal distribution function of the tension and s...

Embodiment 2

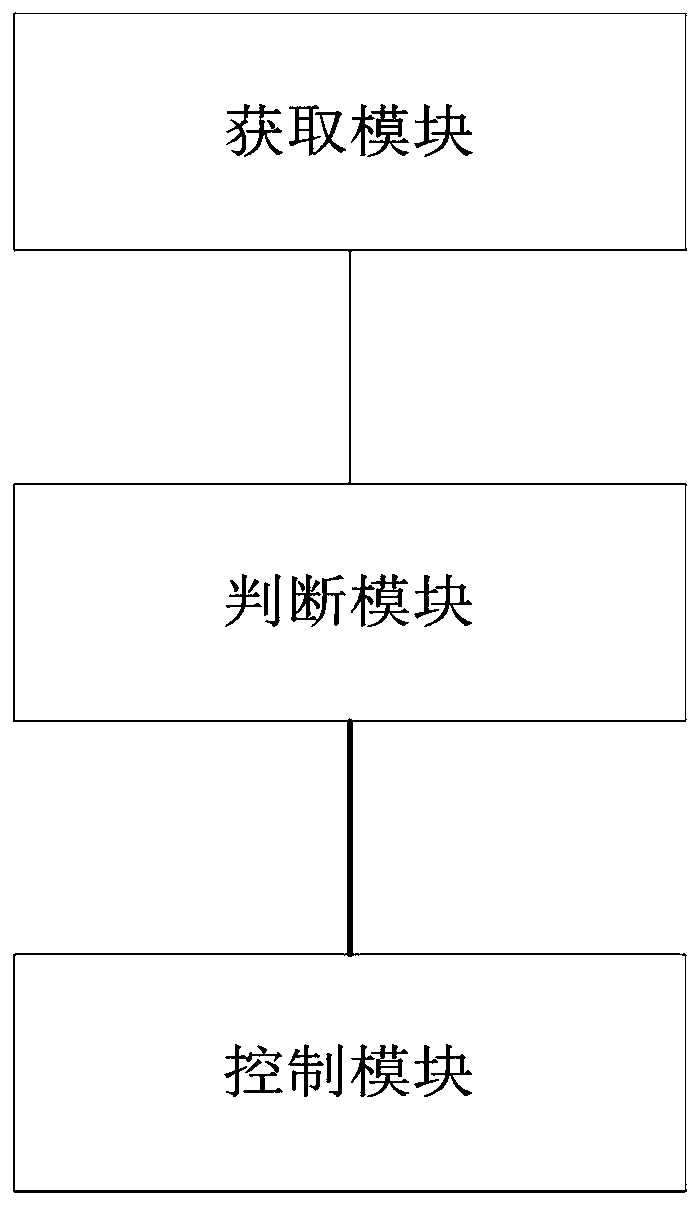

[0069] Based on the same inventive concept as in Embodiment 1, this embodiment provides a slab caster control system for the slab continuous casting process section. The slab continuous casting process section includes a fan-shaped process section. There are tension levelers in the inner and outer arcs of the fan-shaped process section at the same time, see figure 2 , the system includes:

[0070] The acquisition module is used to acquire the driving roll gap deviation value, the driven roll roll gap deviation value, the inner and outer arc tension correction force deviation and the inner and outer arc tension deviation of the fan-shaped process section in real time during the continuous casting process of the slab continuous casting process section. Corrective force difference ratio;

[0071] A judging module, used to judge whether the following requirements are met: the gap deviation of the driving roller ≤ ± 2mm, the gap deviation of the driven roller ≤ ± 0.5mm, the devia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com