High-density polyethylene (HDPE) hollow shake-proof splicing storage box

A storage box, hollow technology, applied in container handles, packaging, transportation and packaging, etc., can solve the problems of heavy transportation and handling, no reusability, high manufacturing cost, etc., achieve light load, reusability, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] To make the technical problems solved by the present invention, the adopted technical solutions and the achieved technical effects clearer, the technical solutions of the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

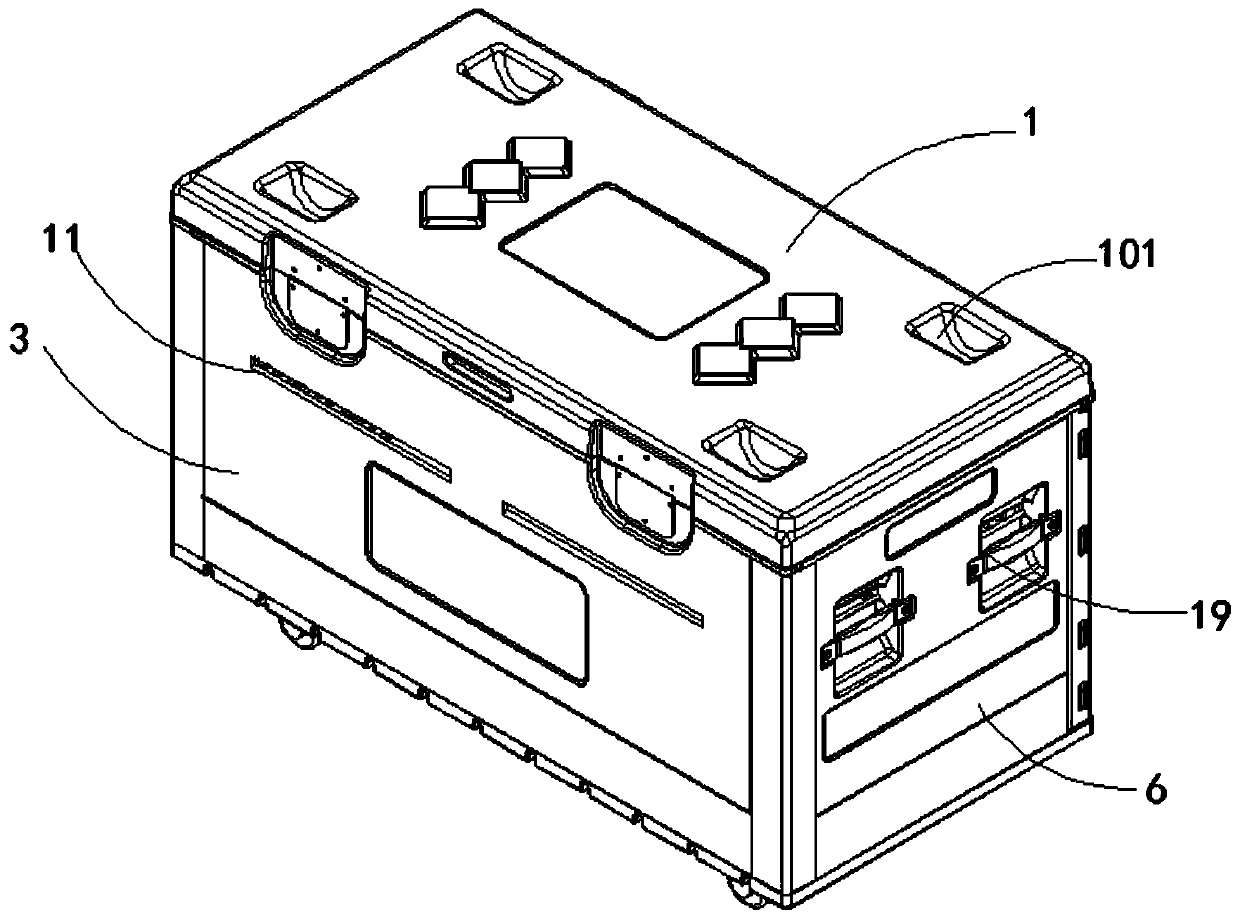

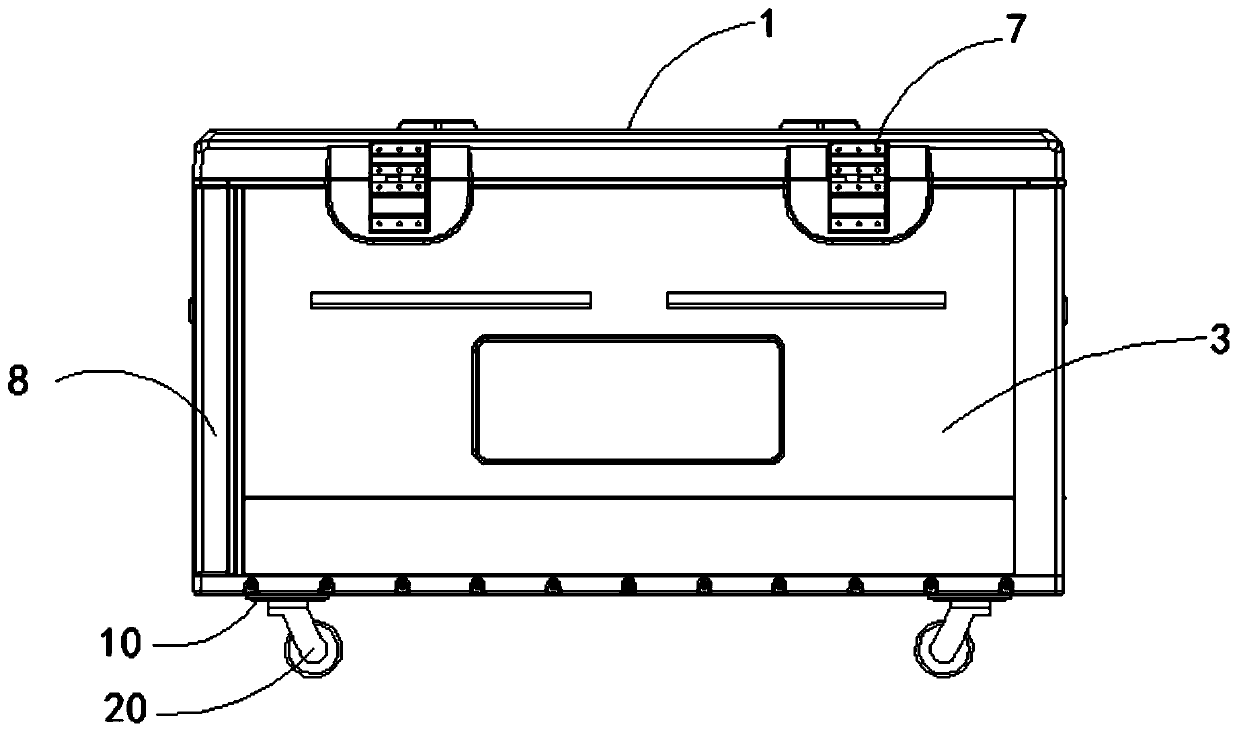

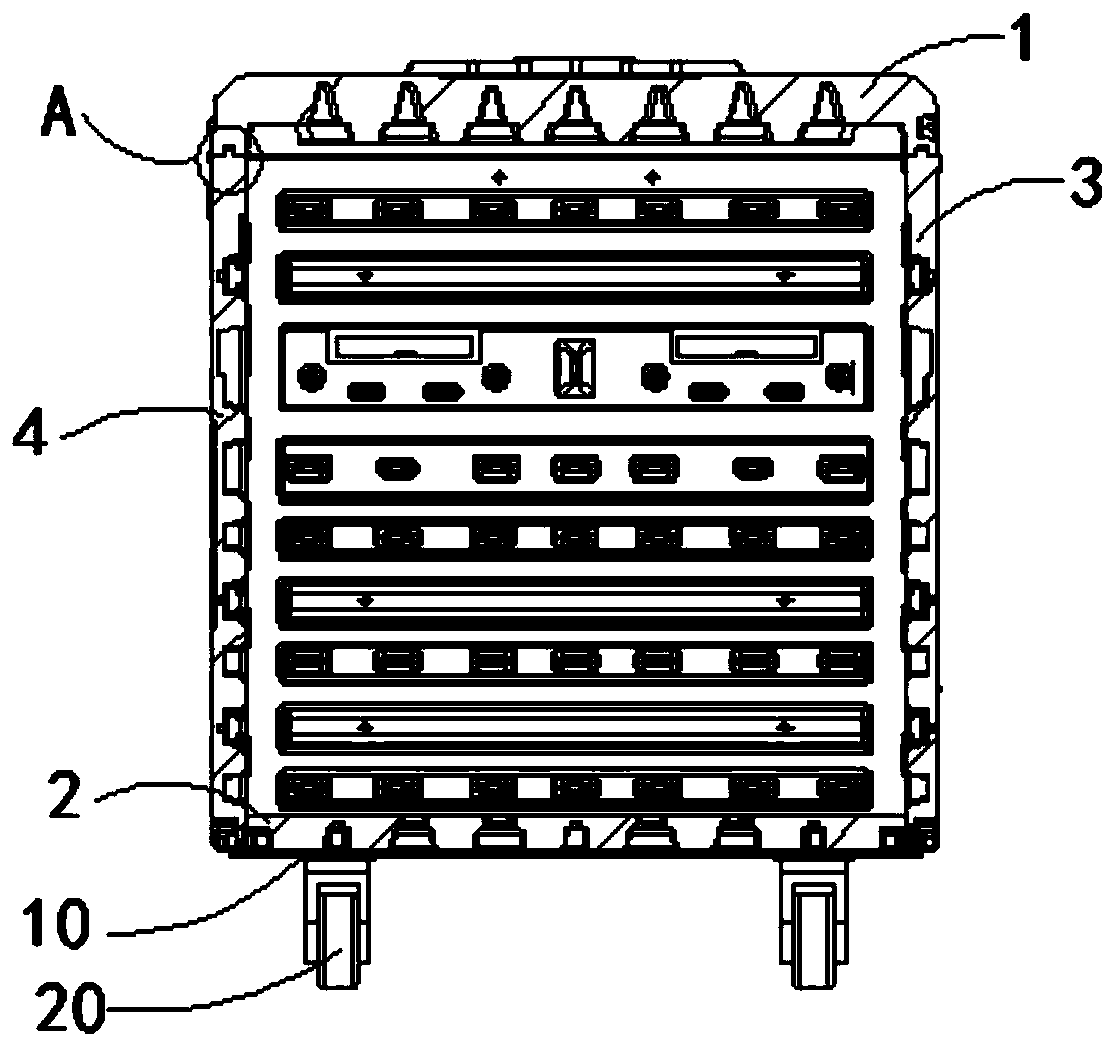

[0032] Such as Figure 1-8 A HDPE hollow anti-vibration assembled storage box shown includes an upper cover plate 1, a bottom plate 2, a front plate 3, a rear plate 4, a left side plate 5 and a right side plate 6; the front plate 3, the left side plate 5, Both the rear plate 4 and the right side plate 6 are engaged and fixed with the bottom plate 2; A storage cavity is formed on the top; the upper cover plate 1 is arranged at the opening of the storage cavity, and the upper cover plate 1 and the rear plate 4 are hinged through hinges;

[0033] The junction of the front panel 3 and the left panel 5, the junction of the front panel 3 and the right panel 6, the junction of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com