Mounting method of large storage tank floating tray guide pipe flexible sealing device

A technology for flexible sealing and large storage tanks, applied in protection devices, large containers, packaging, etc., can solve problems such as oil and gas leakage, and achieve the effect of eliminating static electricity accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

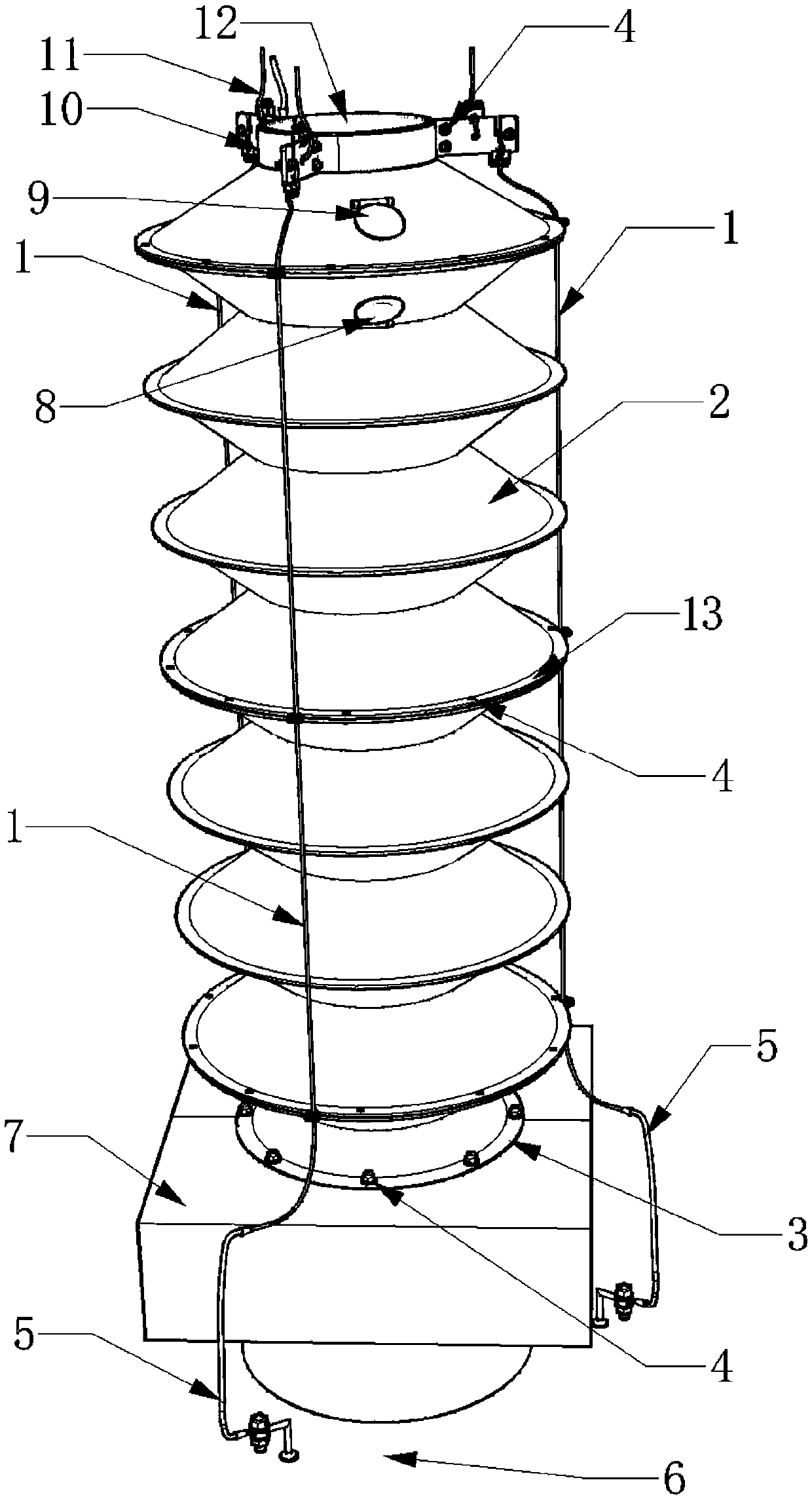

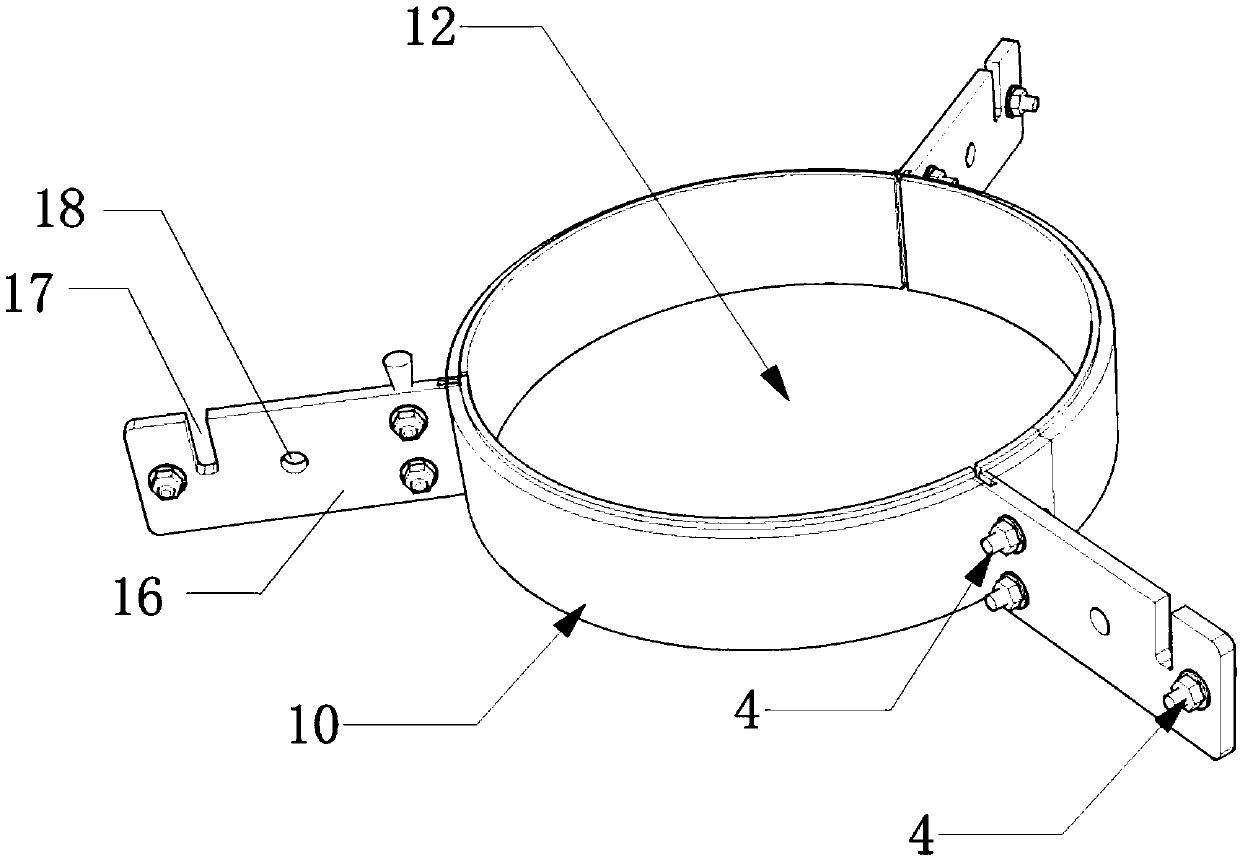

[0040] Embodiment 1 of the present invention describes a flexible sealing device for a floating plate guide pipe of a large storage tank.

[0041] Such as figure 1 As shown, the flexible sealing device for the guide tube of the floating plate of the large storage tank includes a base 7, a flexible sealing tube 2, a sealing ring 10 and other components. in:

[0042] The base 7 is installed on the position above the floating plate 6 where the guide tube 12 passes, and surrounds the perforation on the guide tube 12 .

[0043] Preferably, the installation method of the base 7 can be welded connection, for example.

[0044] A through hole (not shown) through which the guide tube 12 passes upward is provided on the top of the base 7 .

[0045] The flexible sealing tube 2 is set on the guide tube 12 . in:

[0046] The bottom of the flexible sealing tube 2 is fixed on the base, and the fixing method is, for example:

[0047] A first reinforcement ring 3 is provided at the bottom...

Embodiment 2

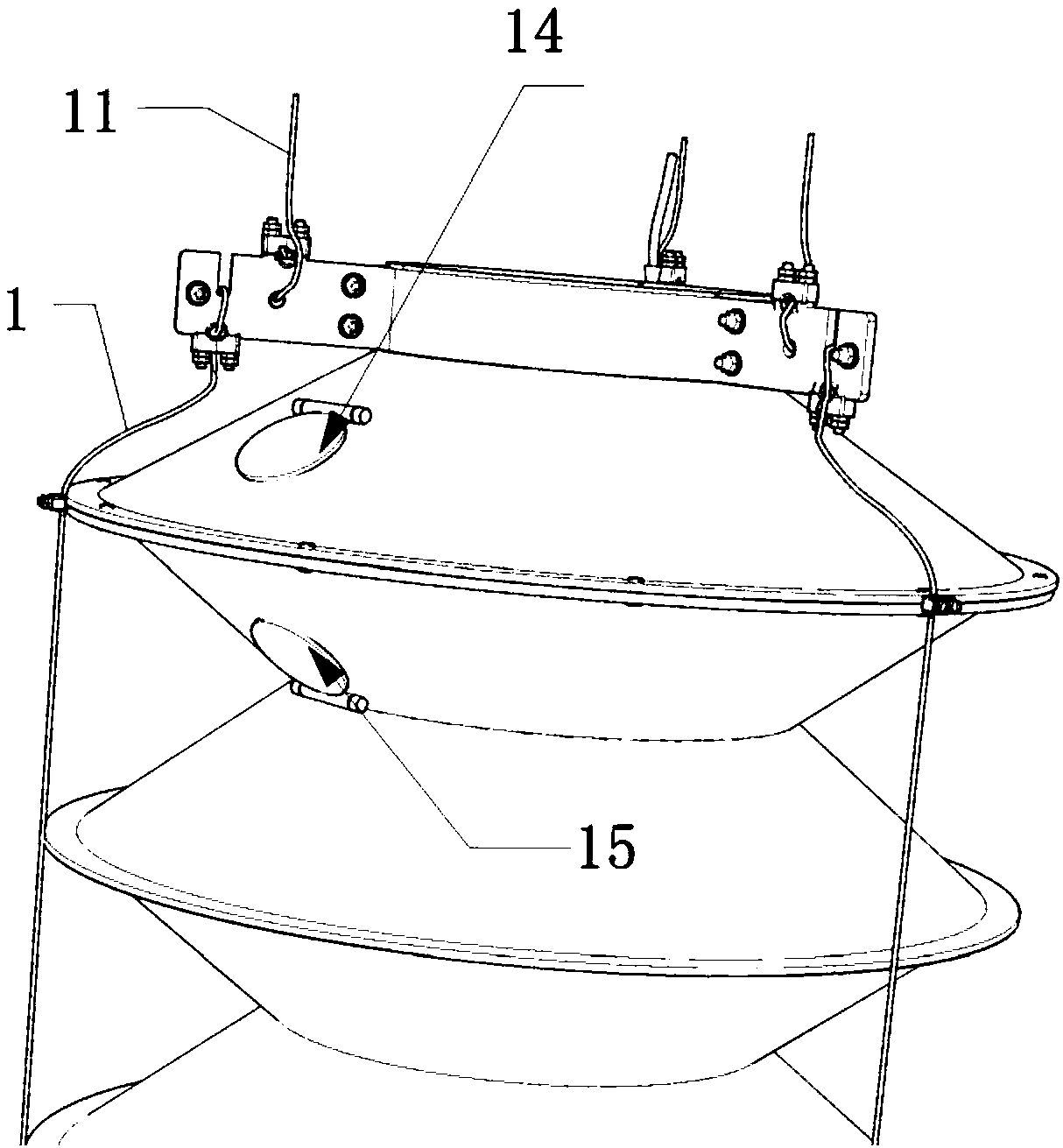

[0057] This embodiment 2 also refers to a flexible sealing device for the guide pipe of the floating plate of a large storage tank. The flexible sealing device is different from the above-mentioned embodiment 1 in the following technical features, and other technical features can refer to the above-mentioned embodiment 1.

[0058] The top of the flexible sealing tube 2 in Embodiment 2 is provided with an outer self-closing hole 9 and an inner self-closing hole 8 .

[0059] When the pressure in the flexible sealing tube 2 increases to the first set threshold, the outer self-closing hole 9 exhales, and the inner self-closing hole 8 is sealed; when the pressure in the flexible sealing tube 2 decreases to the second setting threshold, The inner self-closing hole 8 sucks air, and the outer self-closing hole 9 is airtight.

[0060] Through the above-mentioned outer self-closing hole 9 and inner self-closing hole 8, the pressure adjustment can be automatically realized when the press...

Embodiment 3

[0070] This embodiment 3 also describes a flexible sealing device for the guide pipe of the floating plate of a large storage tank. Except for the following technical features that are different from the above-mentioned embodiment 2, other technical features of the flexible sealing device can refer to the above-mentioned embodiment 2.

[0071] A second reinforcing ring 13 is arranged on the flexible sealing tube 2 at intervals from top to bottom.

[0072] The second reinforcing ring 13 is connected with the flexible sealing tube 2 (for example, connected with bolts 4 ).

[0073] The flexible sealing device also includes several reinforcing ropes 1 .

[0074] Wherein, the top of the reinforcing rope 1 is fixed on the sealing ring 10 , and the bottom of the reinforcing rope 1 is connected with the floating disc 6 .

[0075] The circumference of each second reinforcing ring 13 is respectively provided with several U-shaped slots (not shown) for fixing the reinforcing rope.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com