Installation method for stainless steel anti-explosion and fireproof all-welded honeycomb core inner floating disc

An installation method and honeycomb core technology, which is applied to the installation field of stainless steel explosion-proof, fire-proof and fully welded floating discs in the honeycomb core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 of the present invention describes a floating disk module.

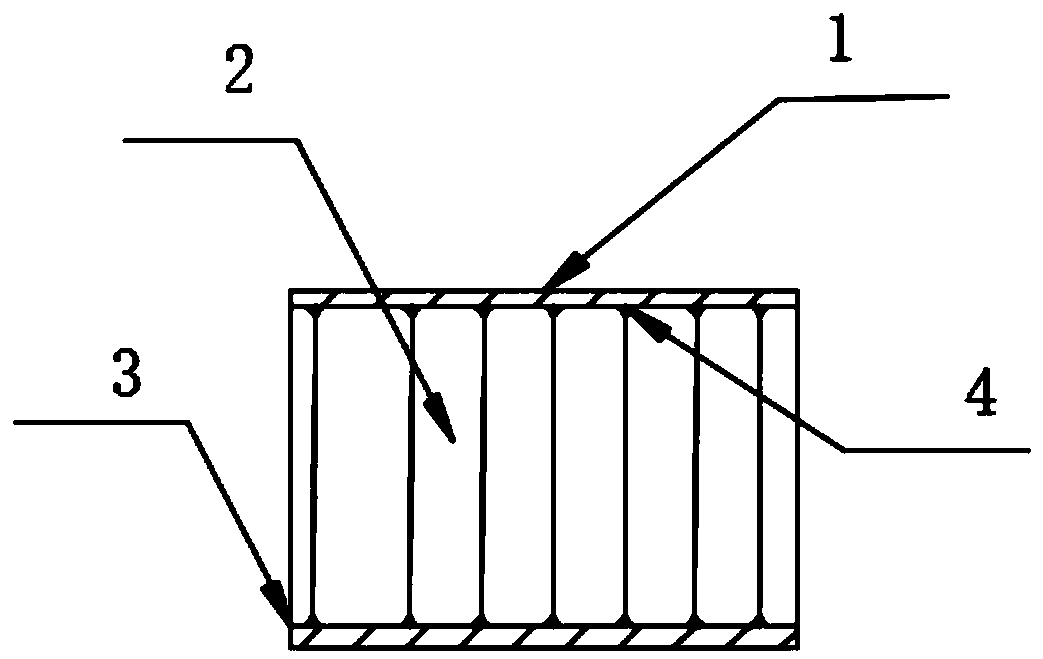

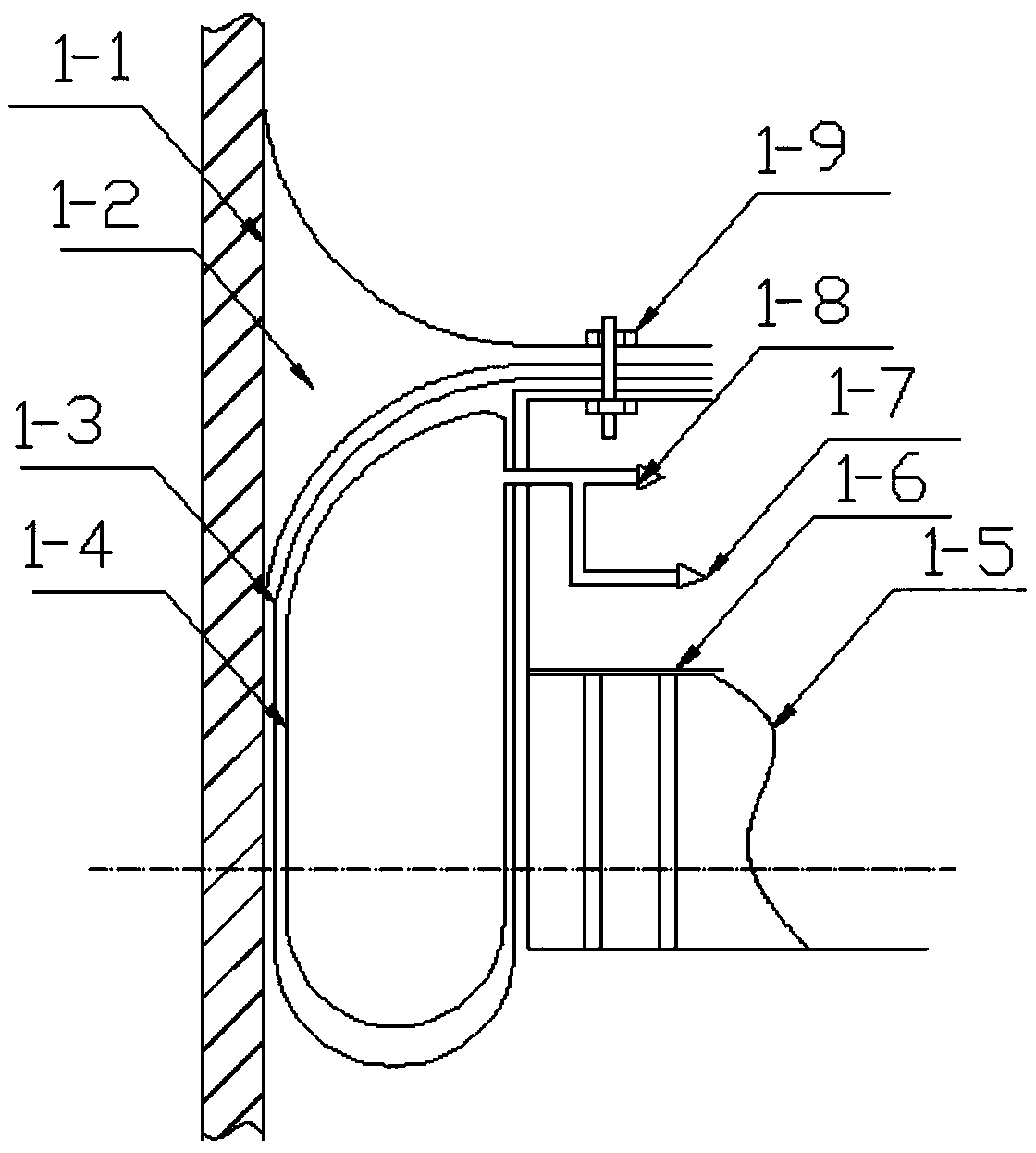

[0032] Such as figure 1 As shown, the floating disk module includes components such as an upper cover 1 , a honeycomb core 2 and a lower cover 3 .

[0033] Wherein, the honeycomb core 2 is located between the upper cover plate 1 and the lower cover plate 3 .

[0034] The honeycomb core 2 is, for example, a hexagonal honeycomb core.

[0035] A plurality of evenly distributed, independent and discontinuous honeycomb holes are arranged on the hexagonal honeycomb core 2 .

[0036] Each honeycomb hole is a buoyancy unit.

[0037] Both the upper cover plate 1 and the lower cover plate 3 in this embodiment 1 are made of stainless steel, so they have fire and explosion-proof properties.

[0038] The honeycomb core 2 in this embodiment 1 is made of aluminum alloy material, which is light in weight and high in structural strength.

[0039] The upper cover plate 1 is welded to the top of the honeycomb c...

Embodiment 2

[0044] Embodiment 2 of the present invention describes a stainless steel explosion-proof and fire-proof all-welded honeycomb core inner floating plate.

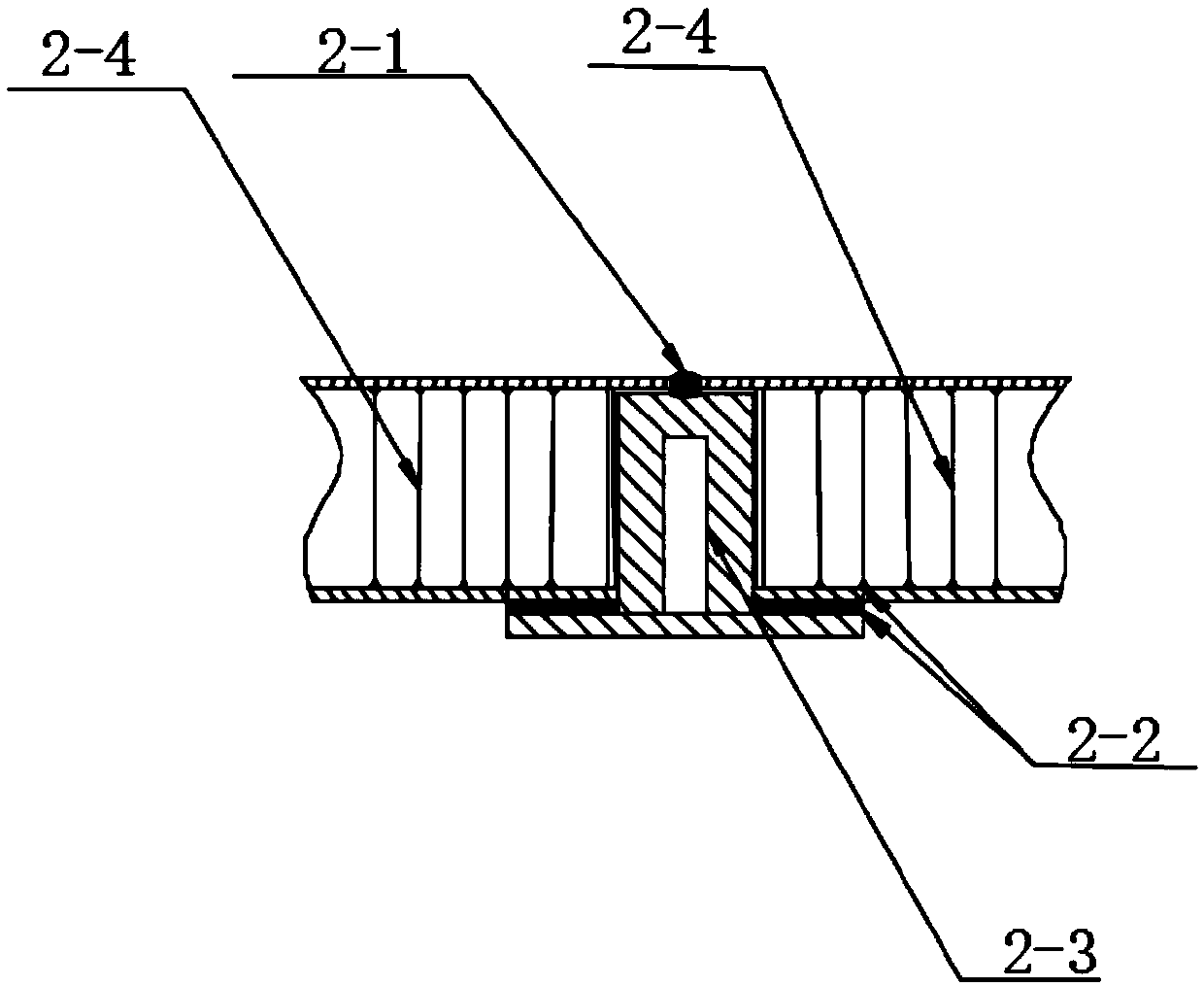

[0045] Stainless steel explosion-proof and fire-proof all-welded honeycomb core inner floating plate, including the main beam and multiple floating plate modules. Wherein, the floating disk module in the second embodiment adopts the floating disk module in the above-mentioned embodiment 1.

[0046] Wherein, two adjacent floating disc modules are connected by welding to form a seal.

[0047] The main beam is in the shape of "Ji"; the main beam and the floating plate module are connected by welding to form a seal.

[0048] Embodiment 2 of the present invention reduces VOCs emissions from the source and achieves energy saving and environmental protection by performing targeted transformation on the leakage points inside the floating disc module, between the floating disc modules, and at the connection between the floating disc ...

Embodiment 3

[0074] This embodiment 3 describes a method for installing a stainless steel explosion-proof and fire-proof all-welded inner floating plate of the honeycomb core.

[0075] This installation method is aimed at the stainless steel explosion-proof and fire-proof all-welded honeycomb core inner floating plate as in the above-mentioned embodiment 2.

[0076] Described installation method comprises the steps:

[0077] The sealed connections between adjacent floating disc modules 2-4 and between the floating disc modules 2-4 and the main beam 2-3 are realized in sequence.

[0078] In Example 3, through the above-mentioned installation method, the installation of the floating plate in the stainless steel explosion-proof and fire-proof all-welded honeycomb core is well realized, and at the same time, it can ensure that the gaps between the floating plate modules are sealed, thereby preventing oil and gas from escaping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com