Cable bent tower and construction method thereof

A cable tower and tower body technology, which is applied to bridge parts, erection/assembly bridges, bridges, etc., can solve the problems of increasing the danger of operators and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

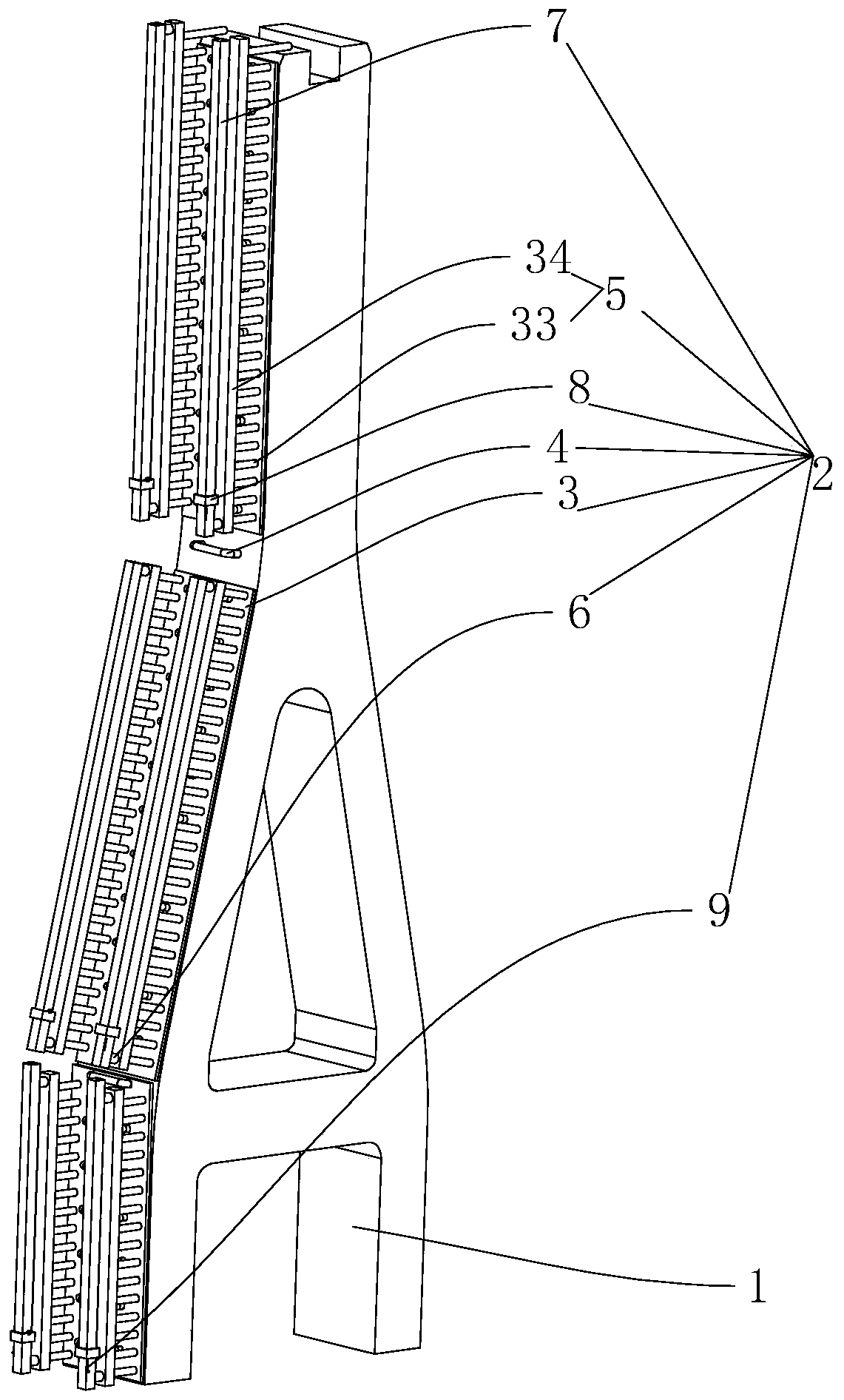

[0035] Embodiment one, such as figure 1 As shown, it is a cable tower disclosed by the present invention, which includes a tower body 1, and a climbing mechanism 2 is provided on the side wall of the tower body 1.

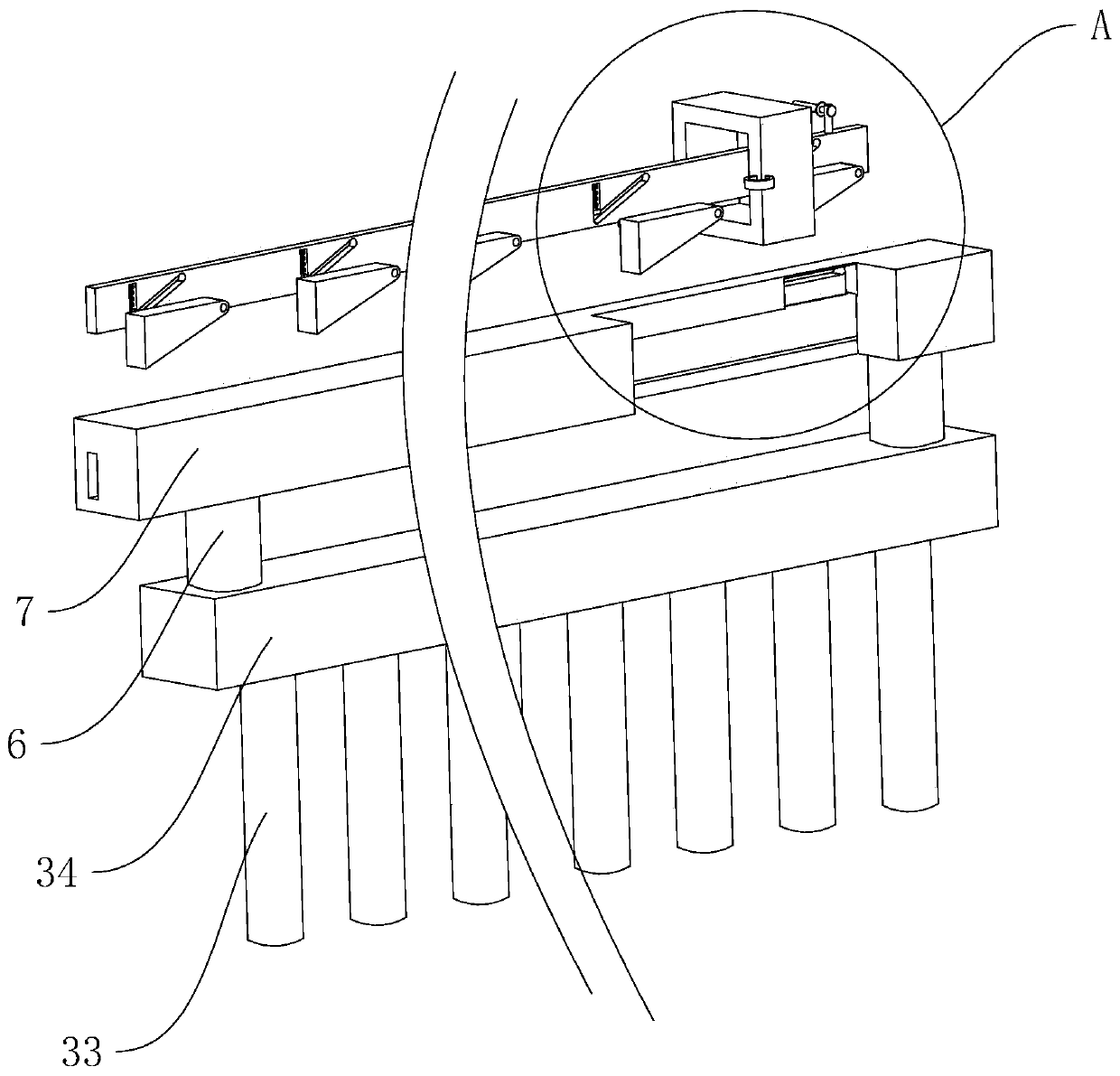

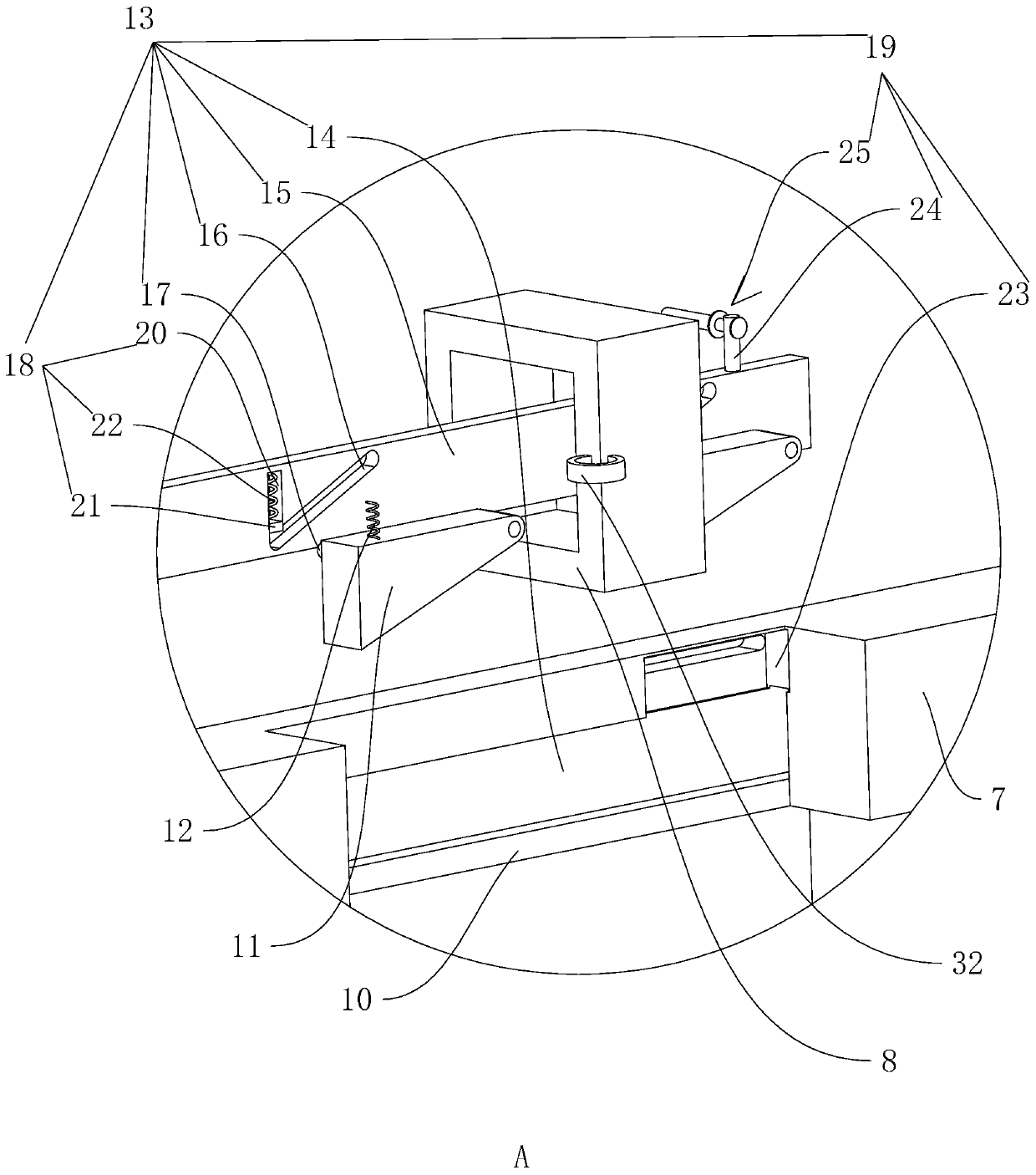

[0036] Such as figure 2 As shown, the climbing mechanism 2 includes a mounting plate 3, a pedal 4, a handrail 5, a mounting rod 6, an anti-off rod 7, an anti-off ring 8 and an anti-off piece 9, and the mounting plate 3 is fixedly connected to the outer wall of the tower body 1 by bolts. One side of the pedal 4 is fixedly connected to the mounting plate 3, several groups of pedals 4 are evenly spaced along the length direction of the mounting plate 3, and a handrail 5 is fixedly connected to both sides of the mounting plate 3, and the handrail 5 includes several groups of one end The vertical bar 33 that is fixedly connected on the mounting plate 3, the cross bar 34 that is fixedly connected on the upper surface of the vertical bar 33, one end of the mounting bar ...

Embodiment 2

[0044] Embodiment two, a kind of construction technique of cable tower, is characterized in that: comprise the following steps,

[0045] Step 1, preparation work, site preparation, raw material preparation, mechanical equipment preparation, technical calculation preparation;

[0046] Step 2: Construction of the lower tower column, measurement and setting out, skeleton installation, steel bar binding, formwork support, pouring, maintenance and formwork removal;

[0047] Step 3, lower beam construction, bracket installation, base film installation, side form installation, inner form installation, pouring, maintenance and form removal;

[0048] Step 4: Middle tower column construction, framework installation, cable conduit installation, steel bar binding, formwork installation, pouring, maintenance and formwork removal;

[0049] Step 5, construction of closing section;

[0050] Step 6, construction of the upper tower column, skeleton installation, cable conduit installation, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com