Intelligent plunger control device and method

A control device and control method technology, applied in pump control, earthwork drilling, mining fluid, etc., can solve problems such as production stoppage, cumbersome manual management work, and flooding, so as to overcome flooding and improve the efficiency of lifting and drainage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

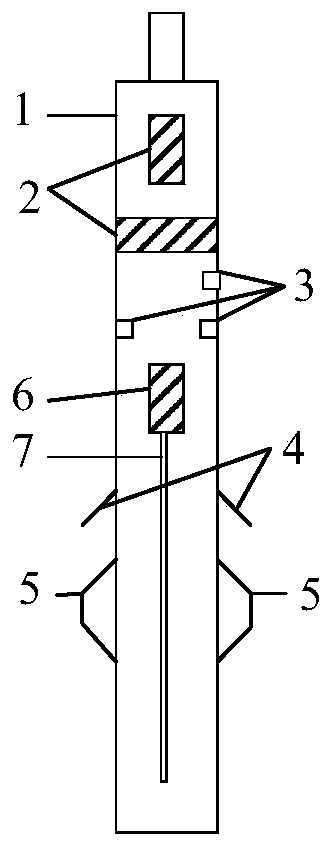

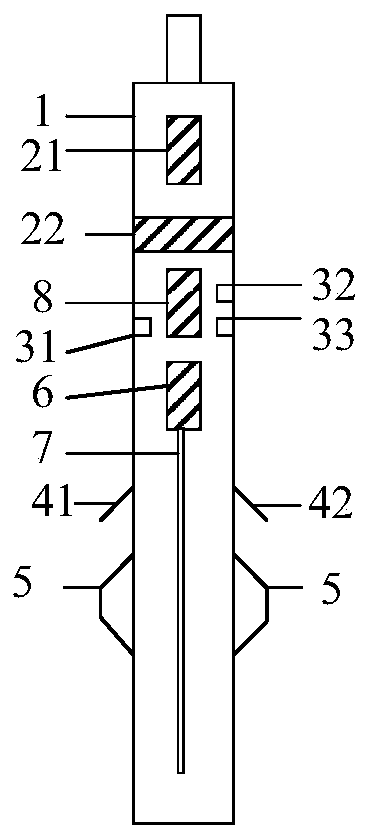

[0045] See figure 1 , 2 , figure 1 It is a schematic structural diagram of an intelligent plunger control device provided by an embodiment of the present invention, figure 2 It is a schematic structural diagram of another intelligent plunger control device provided by an embodiment of the present invention. This embodiment provides an intelligent plunger control device, which includes:

[0046] The ground controller, the smart plunger 1, the ground controller and the smart plunger 1 perform non-contact wireless communication with the smart plunger 1 through coil coupling, wherein,

[0047] The smart plunger 1 is provided with a charging communication module 2 and a sensor assembly 3. The outer wall of the smart plunger 1 is provided with a locking part 4 and a mechanical seal part 5. The mechanical seal part 5 is located below the locking part 4. The smart column The plug 1 is also provided with a motor 6 and a motor transmission rod 7 , the motor 6 is connected to the mo...

Embodiment 2

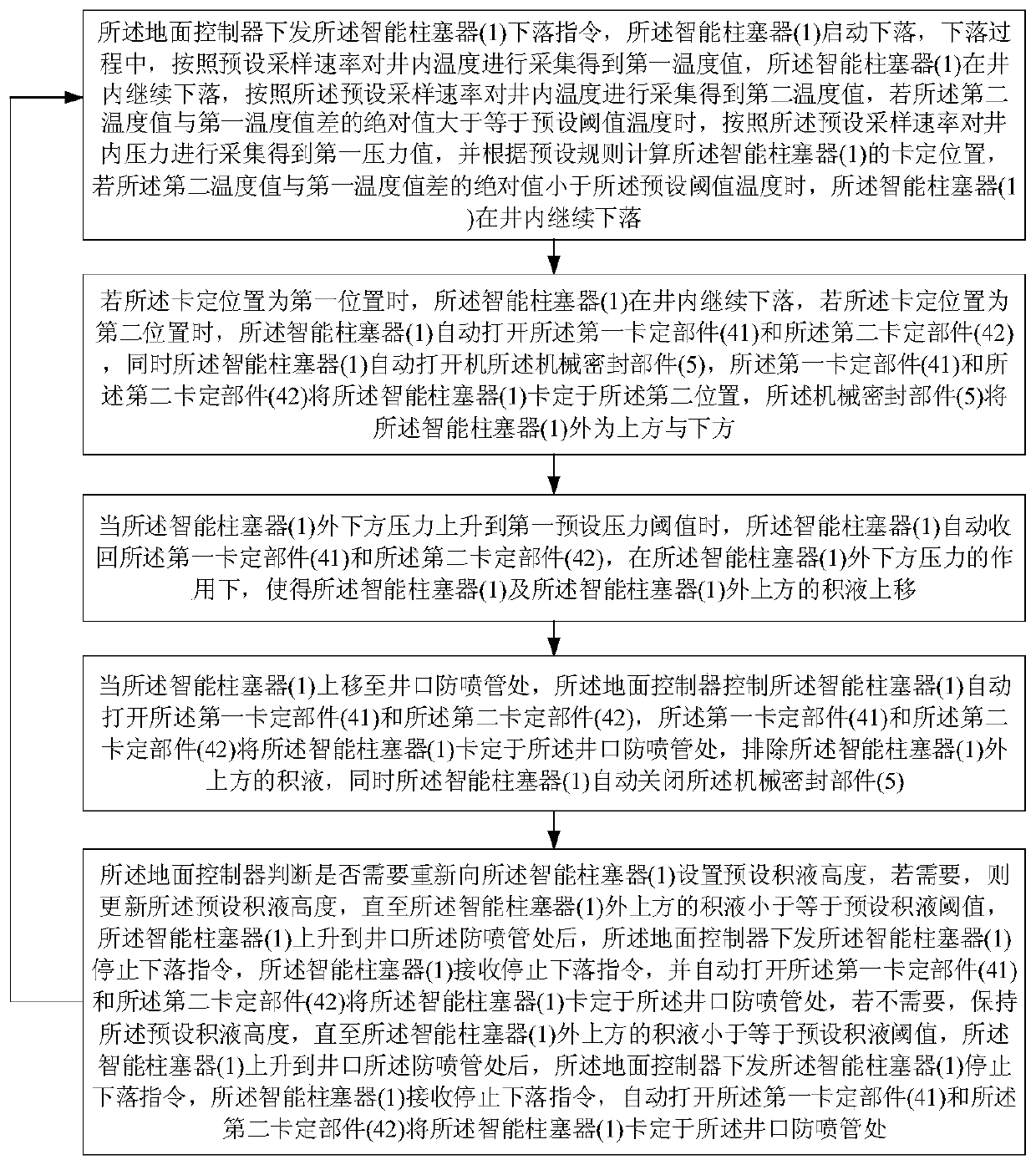

[0057] On the basis of the first embodiment above, please refer to Figure 4 , Figure 4 It is a schematic flowchart of an intelligent plunger control method provided by an embodiment of the present invention. This embodiment provides a smart plunger control method, which is implemented based on the smart plunger control device in Embodiment 1. Specifically, the smart plunger control method includes the following steps:

[0058] Step 1. The ground controller issues the whereabouts command of the smart plunger 1, and the smart plunger 1 starts to fall. During the fall, the temperature in the well is collected according to the preset sampling rate to obtain the first temperature value. The smart plunger 1 is in the The well continues to fall, and the temperature in the well is collected according to the preset sampling rate to obtain the second temperature value. If the absolute value of the difference between the second temperature value and the first temperature value is grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com