Plunger lifting drainage gas recovery downhole device for horizontal shale gas well and working method

A drainage gas recovery, horizontal well technology, applied in wellbore/well parts, pumps with flexible working elements, components of pumping devices for elastic fluids, etc., can solve the problems of inability to effectively discharge wellbore fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]In order to make the objects, technical solutions and advantages of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

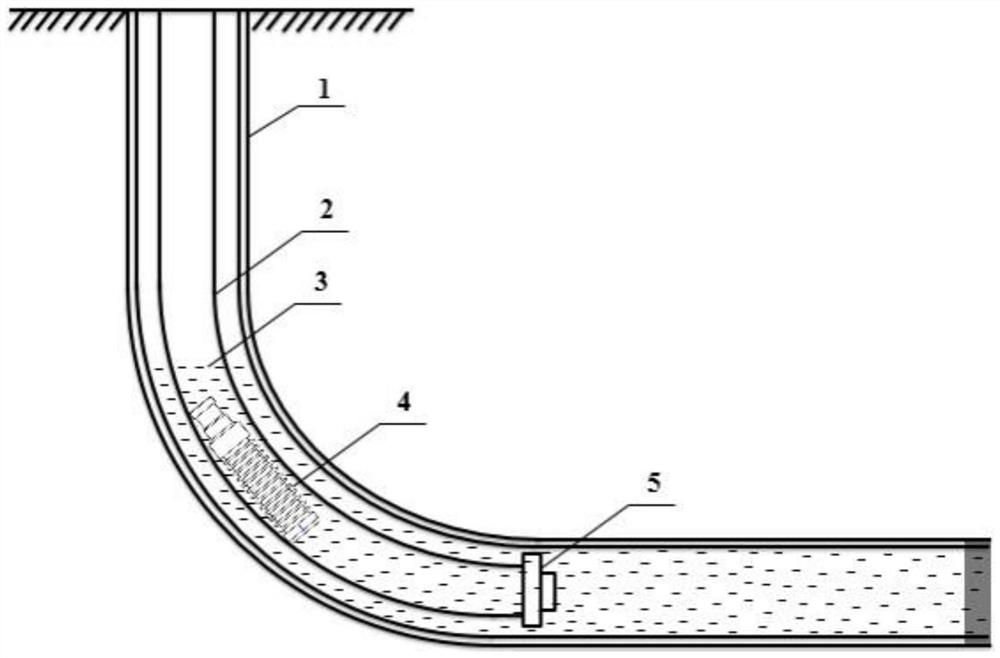

[0013]Such asfigure 1As shown, a shale gas horizontal well plunger lifting drainage gas cooling device, including: sleeve 1, tubing 2, plunger 4 and restricted short contact 5;

[0014]The top of the sleeve 1 is fixed to the wellbore; the tubing 2 is placed in the sleeve 1, and the upper end of the tubing is fixed to the wellhead by the wellhead; the plunger 4 is in the tubing 2, for the lift column, can be in the oil pipe 2 Up and down, the restricted resin is shorted 5 at the bottom of the tubing 2, and the tubing 2 is sleeved, and the limit is shorter than the plunger 4, preventing the plunger 4 from falling out of the oil pipe 2.

[0015]The method of working in the above device, including: After the well, the plunger 4 depends on the wellhead on the wellhead, and the downstream spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com