Test device and method for testing material damage

A material damage and testing device technology, applied in measuring devices, using repetitive force/pulse force to test the strength of materials, analyzing materials, etc. High sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

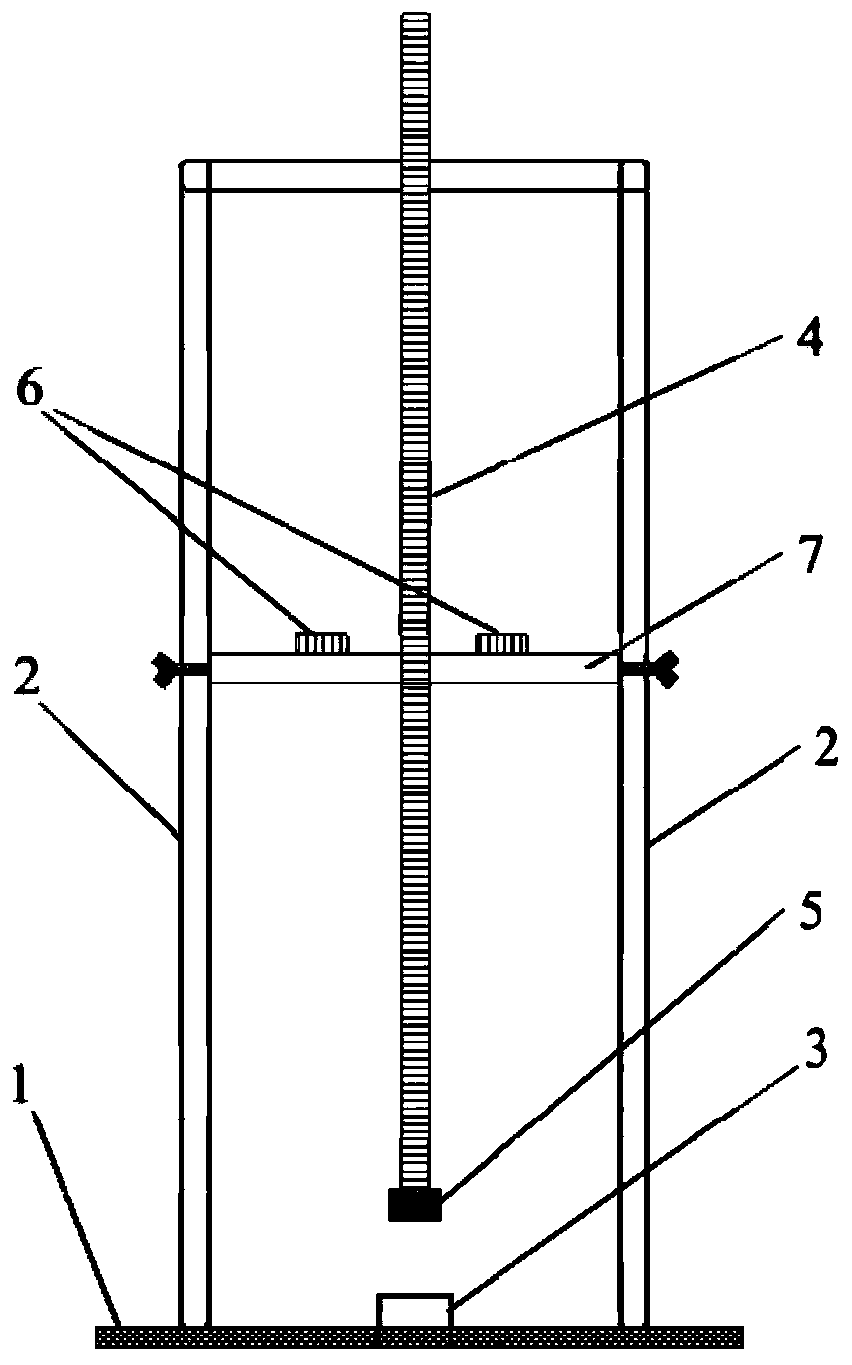

[0049] In this embodiment, the research density is 2960kg / m 3, a granite specimen with an elastic modulus of 63.6GPa and a Poisson's ratio of 0.2 as an example, a test method and device for testing material damage are given. The operation process includes the following steps:

[0050] Step 1: prepare 9 groups of granite specimens, the specimen height is 100mm, and the standard cylindrical sample with a diameter of 50mm;

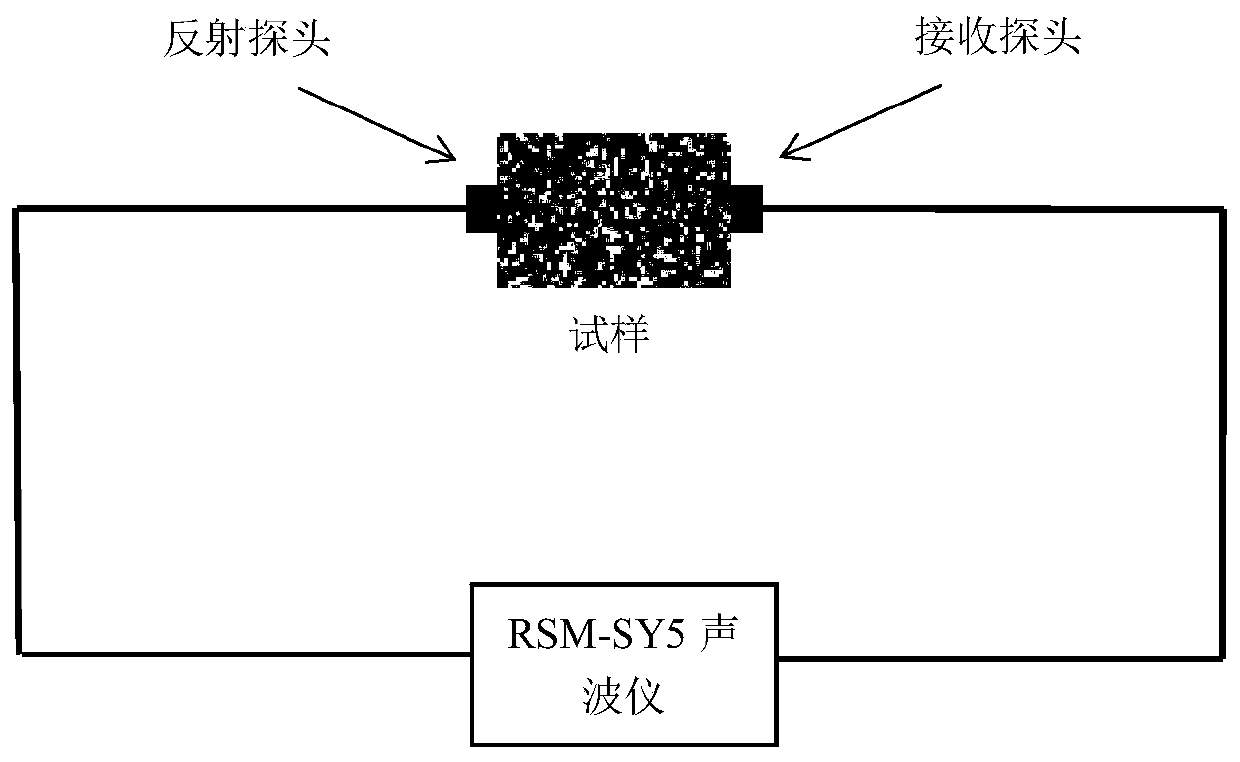

[0051] Step 2: Use the RSM-SY6 acoustic wave detector to measure the ultrasonic velocity of the prepared granite specimen before impact loading;

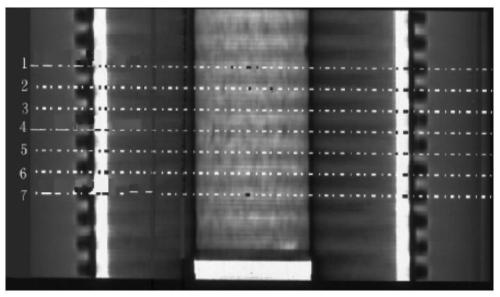

[0052] Step 3, use Philips Brilliance 16-slice high-end spiral CT machine to scan the prepared granite specimen before impact load;

[0053] Step 3: Use three different impact heights: 60cm, 80cm, and 100cm, and three different weights: 200g, 400g, and 600g to impact the concrete samples produced by the drop hammer impact device, and the cycle impact times are 1, 2, 3, 4, 5, 6 times, each trial repeated 3 times; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com